Injection molding process for continuous fiber composite material

An injection molding process and continuous fiber technology, which is applied in the field of continuous fiber composite injection molding process and fiber reinforced composite parts manufacturing, can solve the problems of poor mechanical properties of components and increase of continuous fibers, etc., to achieve strong manufacturing flexibility and production The effect of fast speed and flexible and adjustable process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

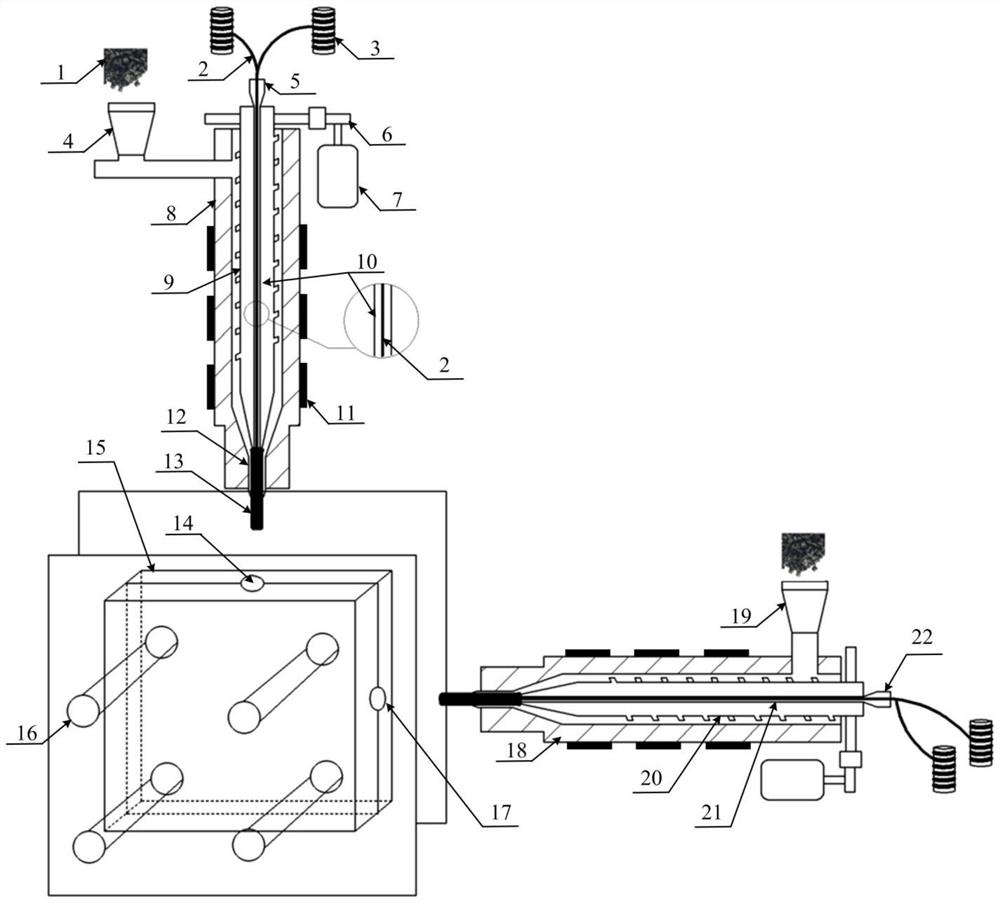

[0030] Below in conjunction with accompanying drawing, the embodiment of the present invention is described in further detail:

[0031] as attached figure 1 As shown, a continuous fiber composite material injection molding process of the present invention, the main materials and parts include: injection material 1, continuous fiber 2, fiber frame 3, vertical hopper 4, vertical continuous fiber feed port 5, gear Box 6, motor 7, vertical barrel 8, vertical screw 9, vertical fiber tube 10, heater 11, nozzle 12, injection beam 13, horizontal injection port 14, mold 15, mold opening and closing device 16, vertical Type injection molding port 17, horizontal barrel 18, horizontal hopper 19, horizontal screw 20, horizontal fiber tube 21, horizontal continuous fiber feed port 22.

[0032] The injection material 1 can be nylon (PA), nylon 6 (PA6), nylon 66 (PA66), polypropylene (PP), polyethylene (PE), polystyrene (PS), polyphenylene sulfide (PPS) ), polycarbonate (PC), acrylonitrile-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com