Device for preparing 3D printing oriented steel fiber reinforced cement-based composite material

A composite material and reinforced cement technology, which is applied in the direction of clay preparation equipment, cement mixing equipment, additive processing, etc., can solve the problems of poor compactness, steel fiber cannot fully play its due role, etc., to improve smoothness, Improve compactness and uniform distribution of steel fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

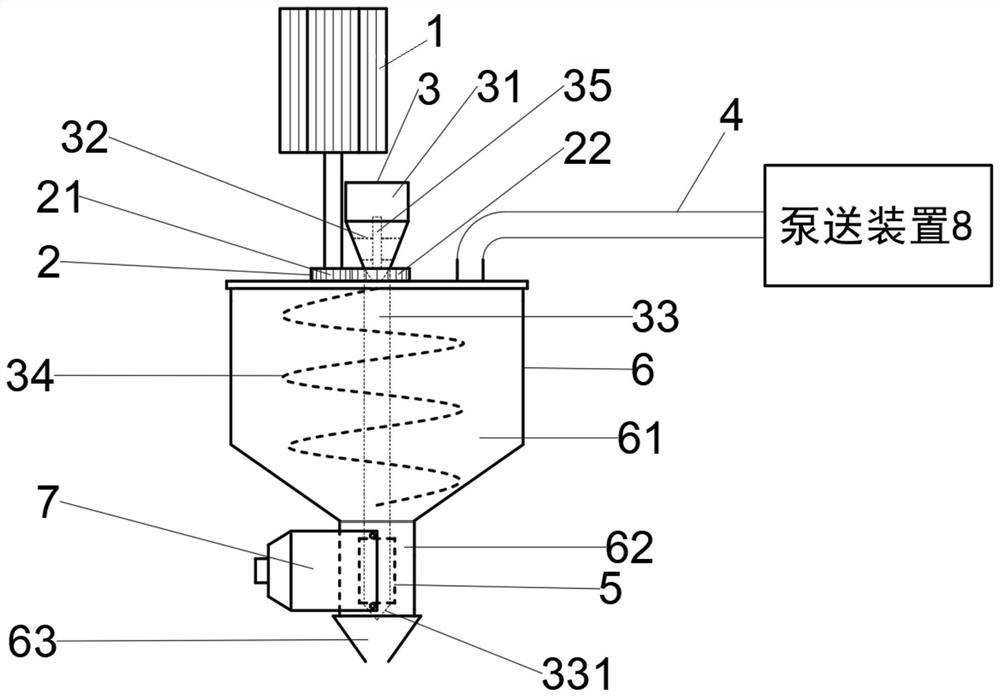

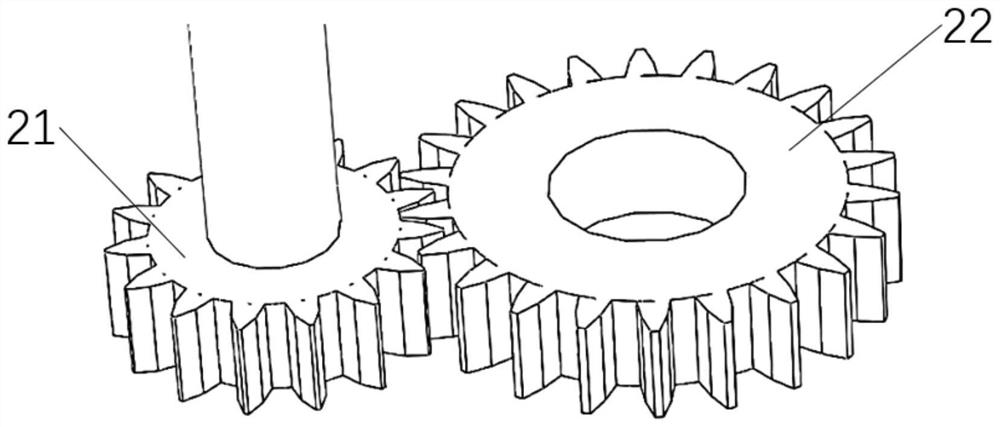

[0048] In this embodiment, the 3D printing device used is the device for preparing 3D printing oriented steel fiber reinforced cement-based composite materials of the present invention: the central axis of the vertical rod 35 is collinear with the central axis of the vertical rotating shaft 33 . The secondary steel fiber orientation unit 5 is a cylindrical AlNiCo or NdFeB permanent magnet; the wall thickness of the cylindrical permanent magnet is 10 mm, and the height is 180 mm. 6 propulsion type stirring blades 32, γ=45°. The upper end surface of the vertical rotation shaft 33 is a conical concave surface, α=40°. β=60°. Twelve steel fiber hole channels 331 with a diameter of 9 mm are opened on the rotating vertical shaft 33 . The diameter of the extrusion port 63 was 30 mm. Steel fiber length is 25mm, diameter is 0.4mm, density is 7.8g / mm 3 , the water-binder ratio of the cement-based composite material mixture is 0.41.

[0049] The preparation process is:

[0050] (1) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com