Preparation method of anti-aging foamed styrene-butadiene rubber

A technology of styrene-butadiene rubber and anti-aging, applied in the field of preparation of foamed styrene-butadiene rubber, can solve problems such as affecting the performance of foamed materials, and achieve the effects of improving anti-aging performance, improving activity and excellent anti-aging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

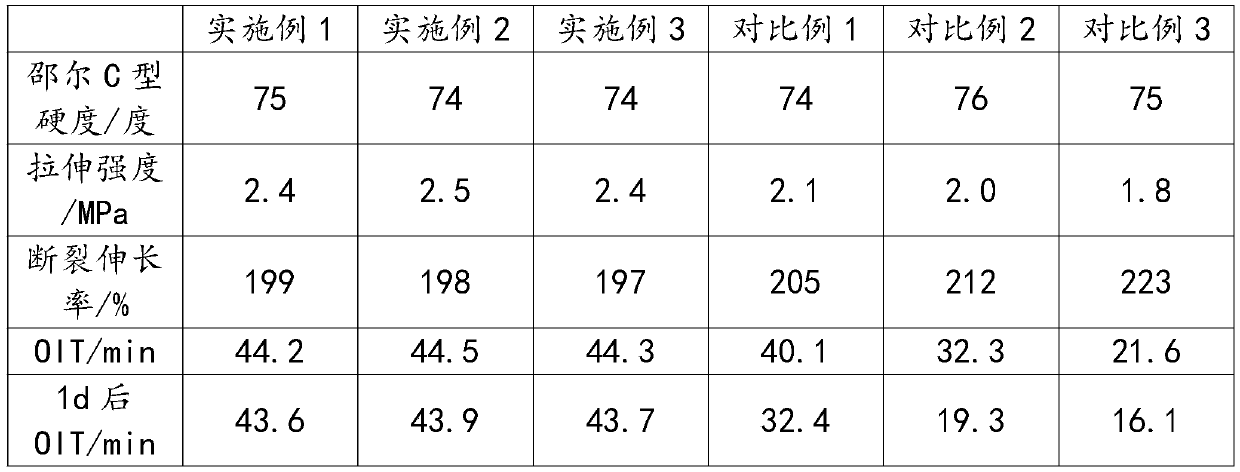

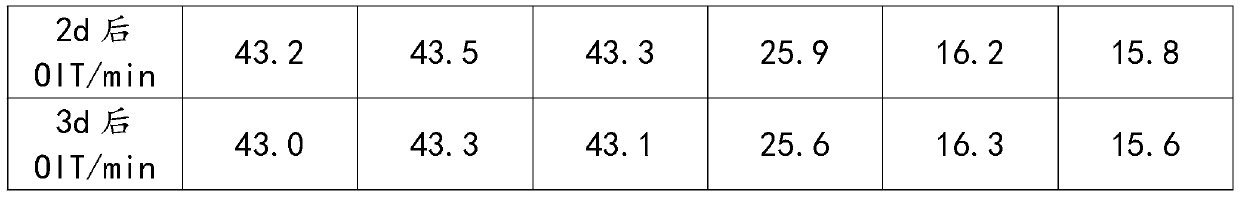

Examples

preparation example Construction

[0023] A preparation method of aging-resistant foamed styrene-butadiene rubber, comprising the steps of:

[0024] The first step is to prepare the raw materials according to the following parts by weight: 90-100 parts of styrene-butadiene rubber, 45-50 parts of modified white carbon black, 8-10 parts of carbon black, 1.6-2 parts of zinc oxide, 12-2 parts of coupling agent 15 parts, accelerator 3-4 parts, sulfur 1.8-2 parts, foaming agent 2.7-3 parts;

[0025] The coupling agent is silane coupling agent Si-69; the accelerator is accelerator TMTD; the foaming agent is OBSH-75;

[0026] The second step is to turn on the internal mixer and set the temperature to 100°C. When the temperature of the instrument reaches the temperature, add styrene-butadiene rubber to the internal mixer for 13-15 minutes, and then add modified white carbon black, zinc oxide and Mixing with coupling agent for 5-6 minutes, then adding foaming agent, sulfur and accelerator to continue mixing for 5-6 minu...

Embodiment 1

[0038] A preparation method of aging-resistant foamed styrene-butadiene rubber, comprising the steps of:

[0039] The first step, prepare each raw material according to the following parts by weight: 90 parts of styrene-butadiene rubber, 45 parts of modified silica, 8 parts of carbon black, 1.6 parts of zinc oxide, 12 parts of coupling agent, 3 parts of accelerator, 1.8 parts of sulfur part, foaming agent 2.7 parts;

[0040] The second step is to turn on the internal mixer and set the temperature to 100°C. When the temperature of the instrument reaches the temperature, add styrene-butadiene rubber to the internal mixer for 13 minutes, and then add modified white carbon black, zinc oxide and coupling Compound mixing for 5 minutes, then add foaming agent, sulfur and accelerator to continue banburying for 5 minutes to obtain the blended rubber;

[0041] Step 3: After the blended rubber is parked at room temperature for 24 hours, set the temperature of the mill to 80°C, mill the ...

Embodiment 2

[0044] A preparation method of aging-resistant foamed styrene-butadiene rubber, comprising the steps of:

[0045] The first step, prepare each raw material according to the following parts by weight: 95 parts of styrene-butadiene rubber, 48 parts of modified silica, 9 parts of carbon black, 1.8 parts of zinc oxide, 13.5 parts of coupling agent, 3.5 parts of accelerator, 1.9 parts of sulfur part, foaming agent 2.8 parts;

[0046] The second step is to turn on the internal mixer and set the temperature to 100°C. When the temperature of the instrument reaches the temperature, add styrene-butadiene rubber to the internal mixer for 14 minutes, and then add modified white carbon black, zinc oxide and coupling Compound mixing for 5.5 minutes, then adding foaming agent, sulfur and accelerator to continue banburying for 5.5 minutes to obtain a blended rubber;

[0047] Step 3: After the blended rubber is parked at room temperature for 24 hours, set the temperature of the mill to 80°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com