Natural silk-reinforced hydroxyapatite/chitosan composite film and preparation method thereof

A technology of hydroxyapatite and nano-hydroxyapatite, which is applied in medical formula, medical science, surgery, etc., can solve the problems of low mechanical properties and fast degradation, and achieve simple preparation methods, accelerated bone growth, and improved mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

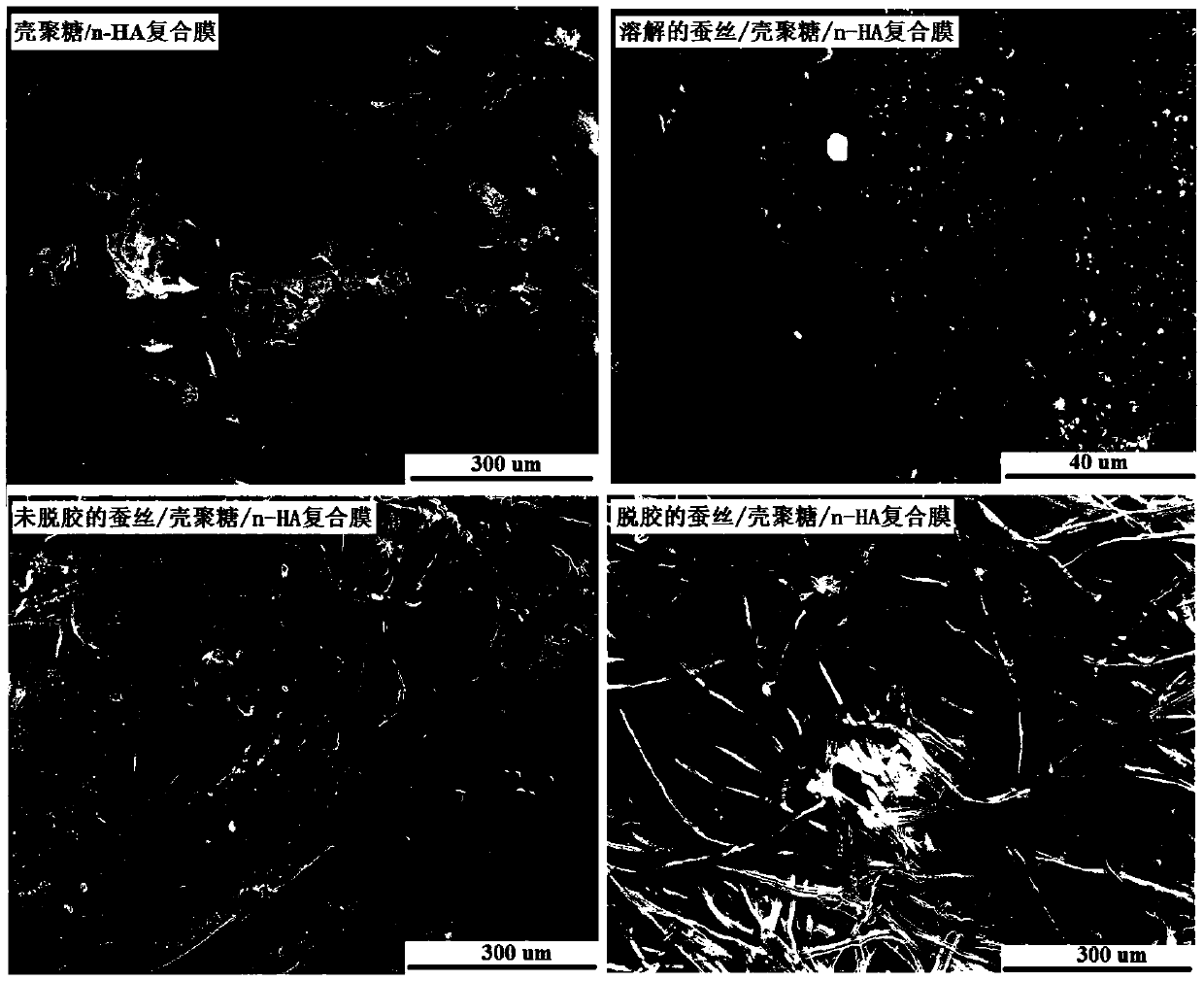

[0013] Example 1: Dissolve 1.0 g of chitosan in 50 ml of 2% glacial acetic acid to obtain light yellow transparent mucus, add 0.2 g of nano-hydroxyapatite powder (average particle size is 25 nm) and add 10 ml of deionized water for ultrasonic After dispersing for 20 minutes, add dropwise to the chitosan solution under high-speed stirring, continue to stir at room temperature for 4 hours, let it stand for defoaming, take half of the above compound solution and cast it on a smooth and dry glass plate to form a film, and then spread it on it Straighten and spread 1.0 g of undegummed silk, then cast the remaining half of the above compound solution on the silk, and dry it naturally to obtain a smooth and dense film. The tensile strength of the composite film was 33 MPa, and the elongation at break was 20%. The film was soaked in simulated body fluid for 24 hours, and the surface of the film was completely covered by bone-like apatite as observed by SEM; the film stretched until 8 w...

Embodiment 2

[0014] Example 2: Dissolve 1.0 g of chitosan in 50 ml of 2% glacial acetic acid to obtain light yellow transparent mucus, add 0.1 g of nano-hydroxyapatite powder (average particle size is 25 nm) and add 20 ml of deionized water for ultrasonic After dispersing for 25 minutes, add dropwise to the chitosan solution under high-speed stirring, continue to stir at room temperature for 4 hours, let it stand for defoaming, take half of the above compound solution and cast it on a smooth and dry glass plate to form a film, and then spread it on it Straighten and spread 1.5 g of undegummed silk, then cast the remaining half of the above compound solution on the silk, and dry it naturally to obtain a smooth and dense film. The tensile strength of the composite film was 36 MPa, and the elongation at break was 27%. The film was soaked in simulated body fluid for 24 hours, and most of its surface was covered by bone-like apatite as observed by SEM; the film stretched until 8 weeks. The tens...

Embodiment 3

[0015] Example 3: Dissolve 1.0 g of chitosan in 50 ml of 2% glacial acetic acid to obtain light yellow transparent mucus, add 0.2 g of nano-hydroxyapatite powder (average particle size is 25 nm) and add 10 ml of deionized water for ultrasonic After dispersing for 25 minutes, add dropwise to the chitosan solution under high-speed stirring, continue to stir at room temperature for 4 hours, let it stand for defoaming, take half of the above compound solution and cast it on a smooth and dry glass plate to form a film, and then spread it on it Straighten and spread 0.5 g of undegummed silk, then cast the remaining half of the above compound solution on the silk, and dry naturally to obtain a smooth and dense film. The tensile strength of the composite film was 29 MPa, and the elongation at break was 24%. The film was soaked in simulated body fluid for 24 hours, and its surface was completely covered by bone-like apatite as observed by SEM; the film stretched until 8 weeks. The tens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com