Pre-pressing forming and intensified sintering method of fine iron ore concentrate

A technology of pre-pressing and strengthening sintering, which is applied in the field of iron and steel metallurgy, and can solve the problems of air permeability of sintering material layer, sinter strength, adverse effects on output and energy consumption, and high production cost that affect the granulation effect of sintering mixture, and achieve broad Promote the value and application prospects, broaden the source of iron-making raw materials, and increase production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

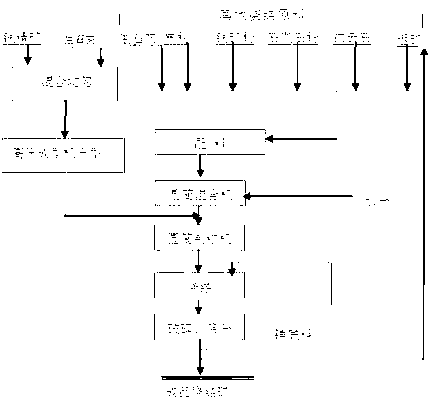

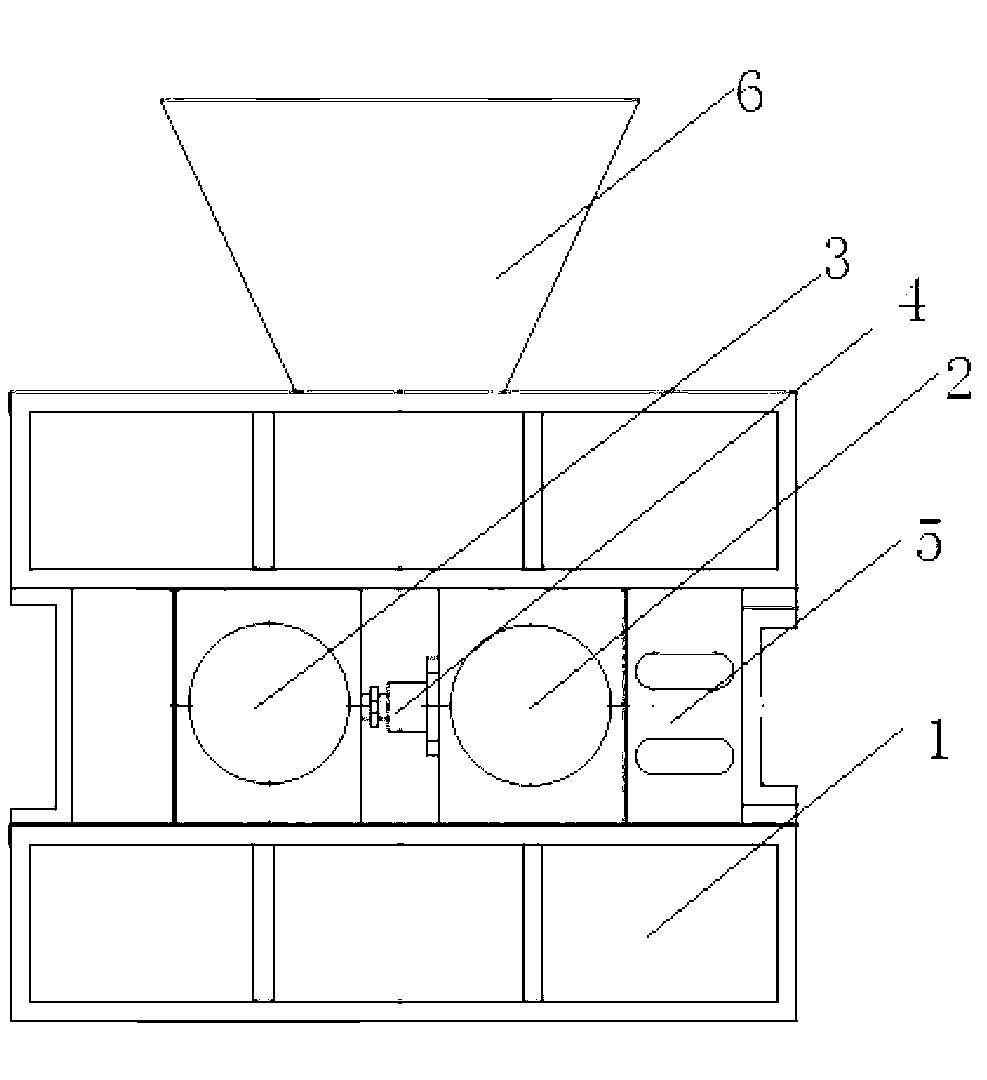

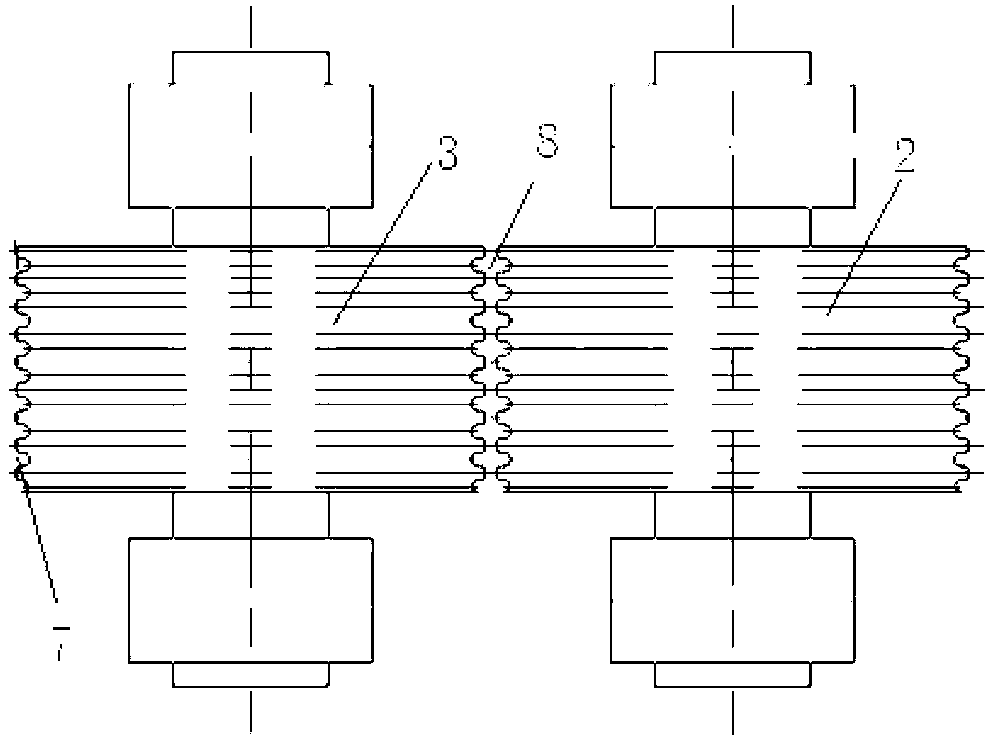

Method used

Image

Examples

Embodiment 1

[0033] The proportion of magnetite fine powder in the total iron raw material is 30%, add 3% quicklime to the magnet fine powder and mix well, the water content of the mixture is 8.4%, and the rolling pressure is 8×10 4 N / mm is pressed into a 3-12mm agglomerate by a high-pressure roller forming machine, and then mixed with other sintering raw materials. The ratio of raw materials is controlled according to the chemical composition of sinter (iron grade 57-58%, basicity CaO / SiO2=2.0, MgO1.5%, SiO2 25.8%) are added after calculation. After the mixture is mixed and granulated by the secondary cylinder, the water content of the mixed pellets is 8.3%, and then sintered. The 3-12mm particle size content in the granulation mixture is 89.3%, and the air permeability resistance of the material layer is reduced to 70mmH 2 O, the yield of sintered ore is 70.14%, and the utilization factor is 1.42t / m 2 h, drum strength 62.45%, sintered solid fuel consumption 64.6kg / t.

Embodiment 2

[0037] The proportion of magnetite concentrate powder in the total iron raw material is 40%, and 5% quicklime is added to the magnetite concentrate powder to mix evenly. The moisture content of the mixture is 8.7%. 4 Under N / mm, it is pressed into a 3-12mm agglomerate by a high-pressure roll forming machine, and then mixed with other sintering raw materials. The ratio of other sinter raw materials is controlled according to the chemical composition of sinter ore (iron grade 57-58%, basicity CaO / SiO2=2.0, MgO1.5%, SiO2 2 5.8%) are added after calculation. The mixture is mixed and granulated by a secondary cylinder, the moisture content of the mixed pellets is 8.4%, and then the mixed pellets are sintered. The 3-12mm particle size content in the granulation mixture is 77.2%, and the air permeability resistance of the material layer is reduced to 100mmH 2 O, the yield of sintered ore is 70.74%, and the utilization factor is 1.30t / m 2 h, drum strength 62.78%, sintered solid fue...

Embodiment 3

[0041] The proportion of magnetite fine powder in the total iron raw material is 50%. After adding 10% quicklime to the magnet fine powder, mix evenly. The water content of the mixture is 9.2%. 4 Under N / mm, it is pressed into a 3-12mm agglomerate by a high-pressure roll forming machine, and then mixed with other sintering raw materials. The ratio of sintering raw materials is controlled according to the chemical composition of sintering ore (iron grade 57-58%, basicity CaO / SiO2=2.0, MgO1.5%, SiO2 2 5.8%) are added after calculation. The mixture is mixed and granulated by the secondary cylinder, the moisture of the mixed pellets is 8.7%, and then the mixed pellets are sintered. The 3-12mm particle size content in the granulation mixture is 65.3%, and the air permeability resistance of the material layer is reduced to 110mmH 2 O, the yield of sintered ore is 65.21%, and the utilization factor is 1.33t / m 2 h, drum strength 61.09%, sintered solid fuel consumption 65.62kg / t.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drum strength | aaaaa | aaaaa |

| Drum strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com