Rotary gas-liquid separator

A gas-liquid separator, rotary technology, applied in the separation method, dispersed particle separation, chemical method of reacting liquid and gas medium, etc., can solve the problem of affecting separation efficiency, long residence time, secondary entrainment of droplets, etc. problem, to achieve the effect of high separation efficiency, convenient application and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

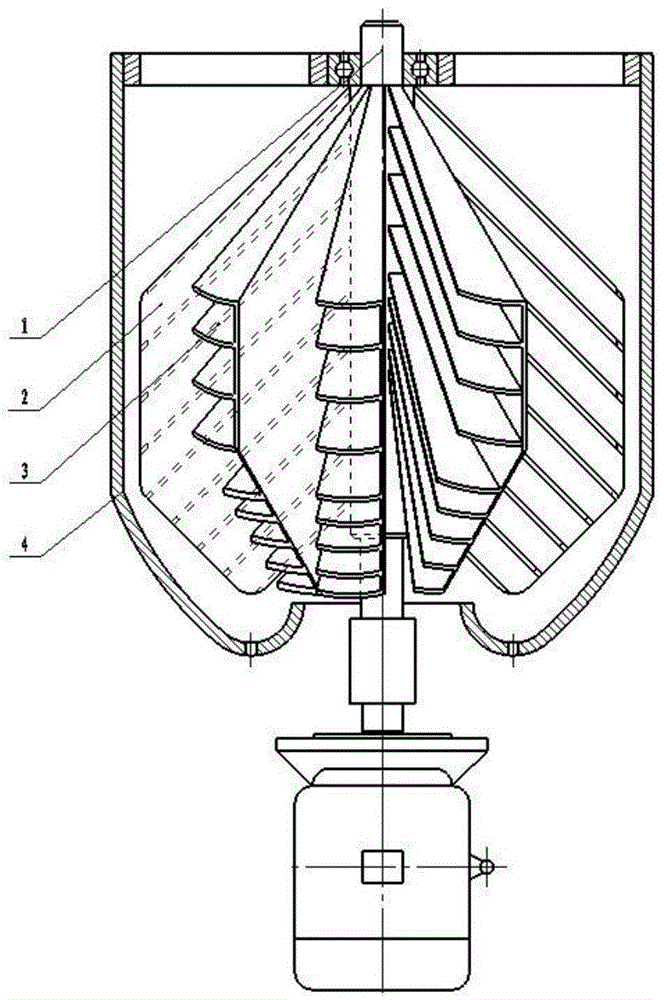

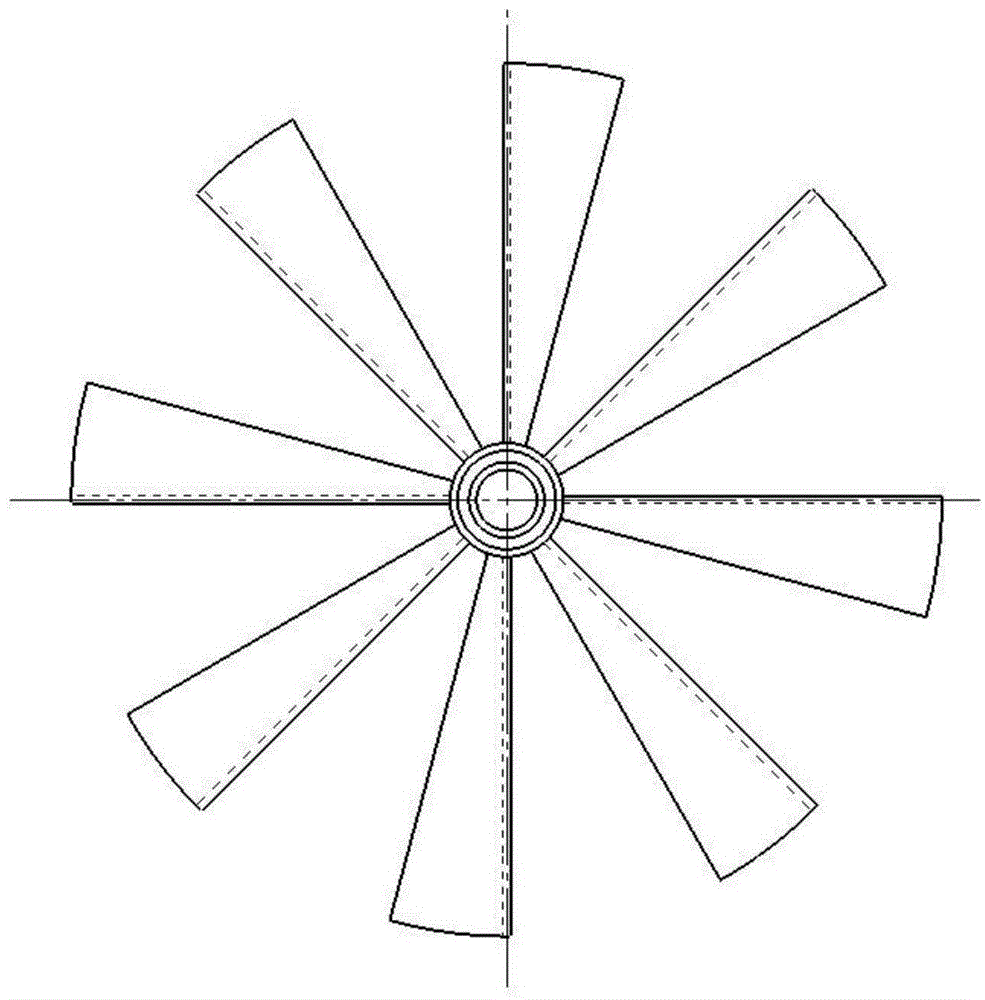

[0031] The present invention will be described in detail below with a typical embodiment, but not limited to this embodiment. See attached figure 1 , The rotary separator device of the present invention includes a rotating shaft, a separation vane, a guide vane and a gas-liquid separator main body.

[0032] The rotating shaft of the rotary gas-liquid separation device rotates at a constant speed driven by the motor, and the separation blades and guide vanes fixed on the rotating shaft rotate synchronously with the rotating shaft. When the gas-liquid mixture enters from the lower port of the main body of the gas-liquid separator, under the action of the rotation of the separation blade and the guide vane, the liquid droplets in the gas phase adhere to the separation vane to form a liquid film, and under the action of centrifugal force, the liquid moves along the guide vane. The sheet moves in the flow direction, and finally attaches to the wall of the main body of the gas-liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com