A Ring Swirl Plate Separator

A swirl plate and separator technology, which is applied in the field of ring-enclosed swirl plate separators, can solve the problems of reduced operating pressure drop and low separation efficiency of small particle size particles, and achieves reduced pressure drop, simple structure, and low difficulty in construction. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

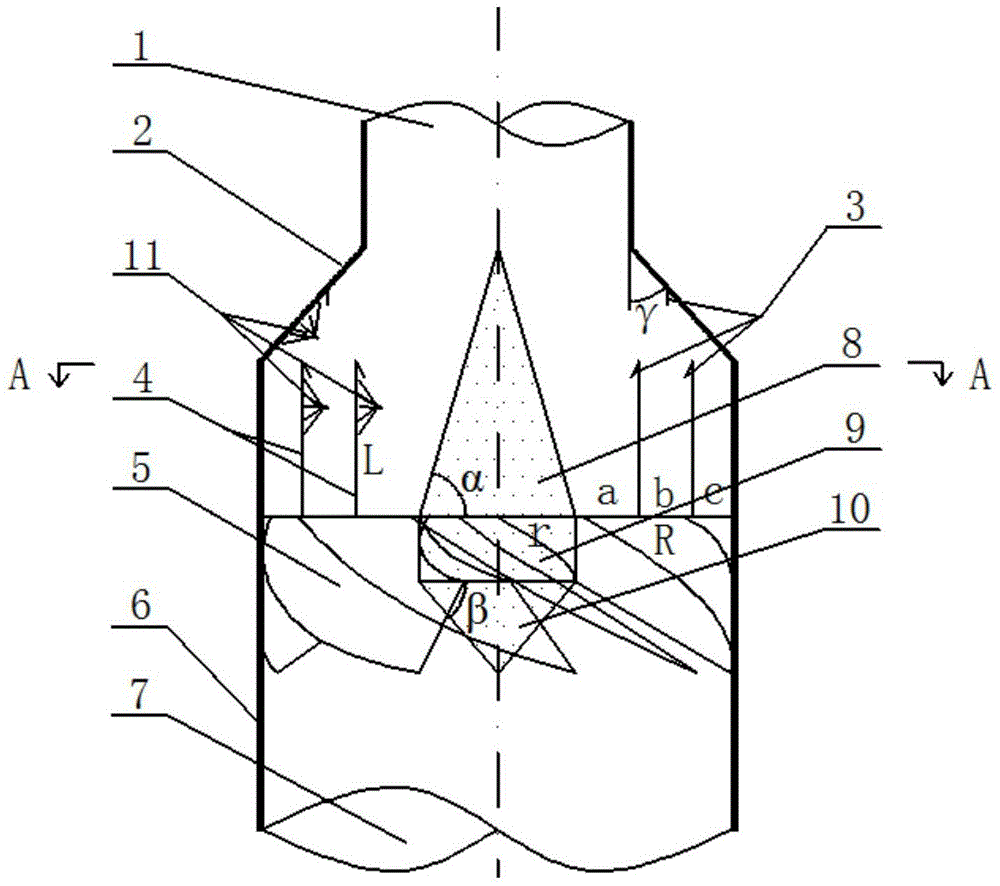

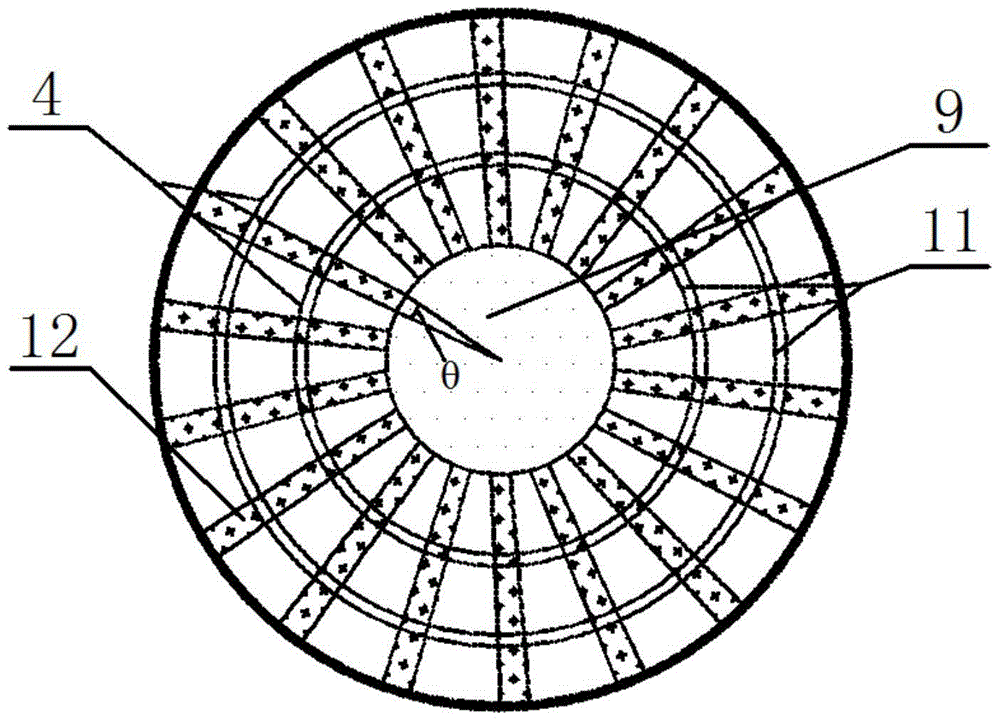

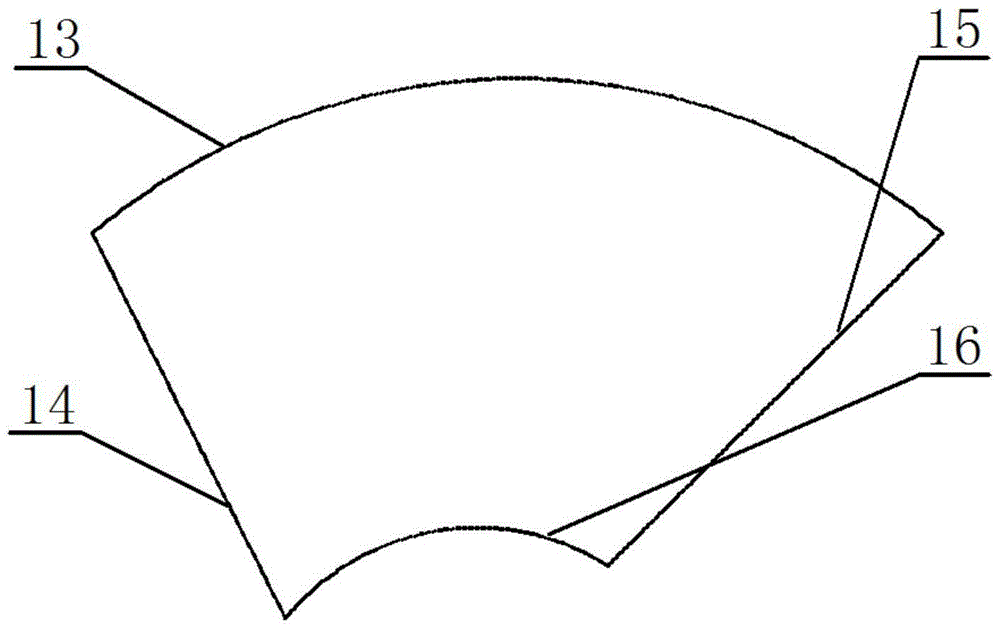

[0039] A ring-encircled swirl plate separator, such as figure 1As shown, a ring-added swirl plate separation device includes a swirl plate 5, a separation ring 4 fixed on the swirl plate 5, a contraction wall 2, an annular cover 11 on the separation ring 4 and the contraction wall 2, and a flushing nozzle 3 , the lower cone 10, the middle cylinder 9 and the upper cone 8. The swirl plate 5 is composed of a plurality of swirl plate blades, which are welded and fixed between the middle cylinder 9 and the outer wall 6. The inclination angle of the swirl plate blades is designed to be between 45°-60°, and the width of the blade overlapping area 12 is consistent inside and outside. , the θ angle is about 5°-15°, and its upper boundary 14 can be horizontal or inclined, but the points with the same radius on all blades are all on the same height, which is convenient for welding and fixing the separation ring 4, the lower boundary of the swirl plate 5 15 is inclined, so as to guide th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com