Gas liquid eddy flow type highly efficient downcomer

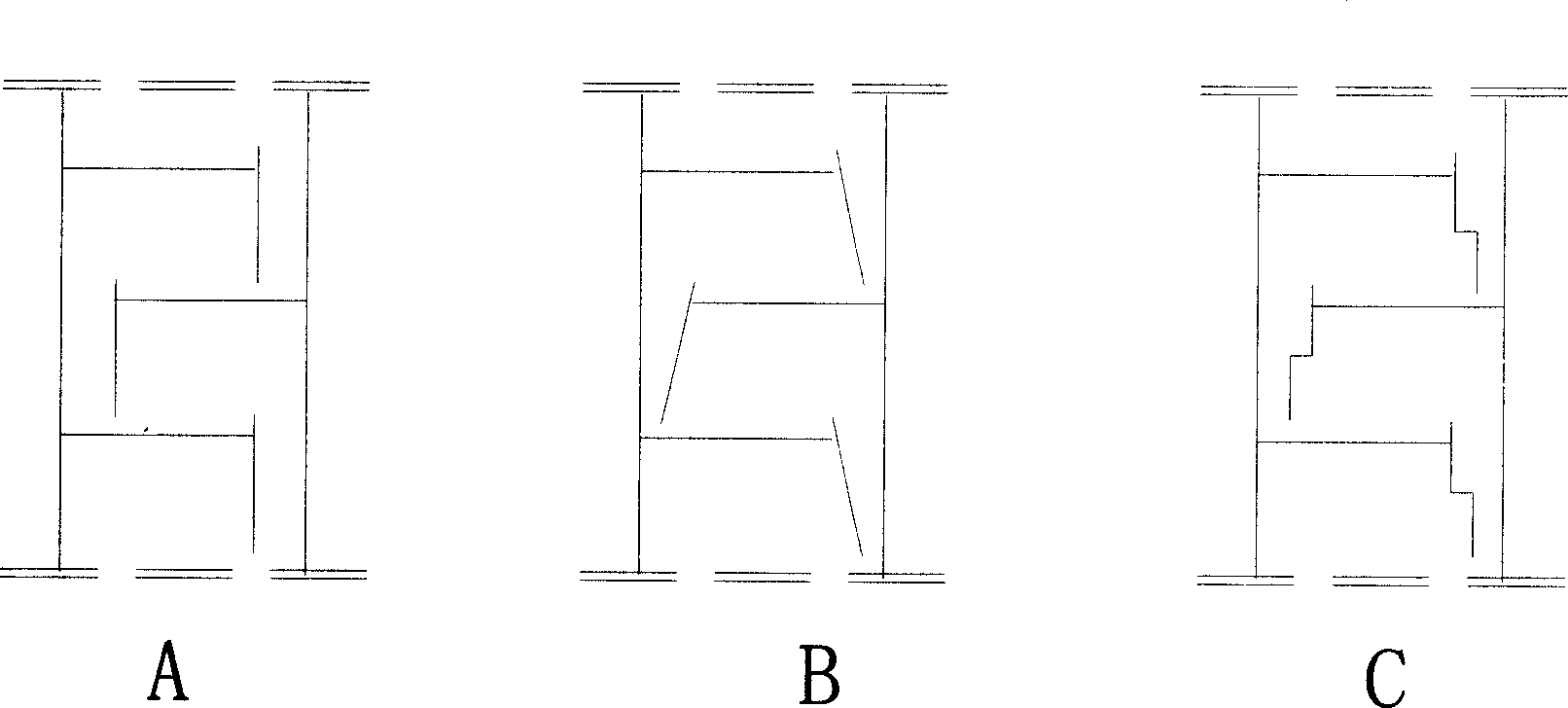

A downcomer and swirl technology, which is applied in the field of high-efficiency gas-liquid swirl downcomers, can solve the problem that the plate area occupied by the downcomer cannot be significantly reduced, the area of the effective area cannot be significantly increased, and the liquid handling capacity cannot be solved. Improvement and other issues to achieve the effect of increasing the area of the effective area, increasing the flux, and avoiding secondary entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

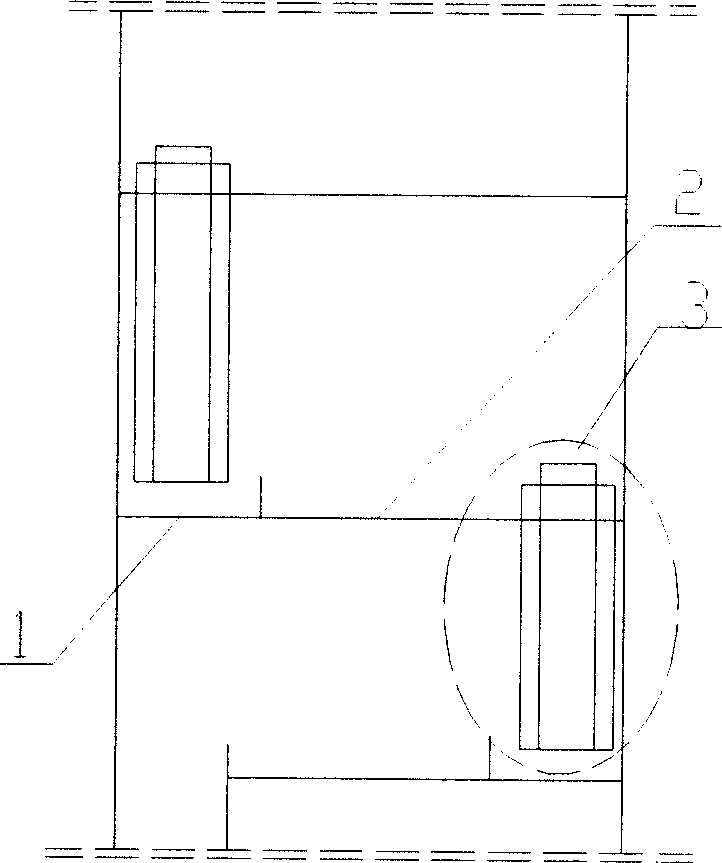

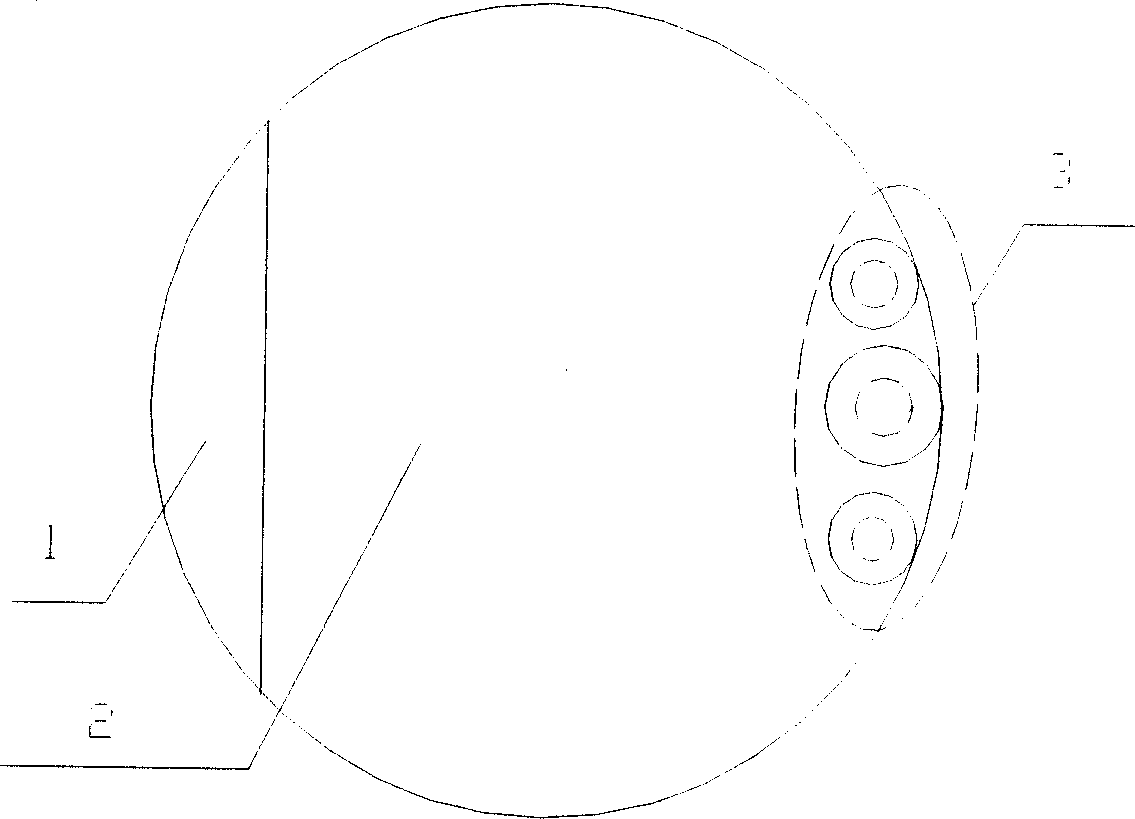

[0018] The present invention is further described in conjunction with accompanying drawing:

[0019] Now take the F-1 float valve tray with a tower diameter of 2500mm and a plate spacing of 550mm, and use the downcomer of the present invention to transform the old standard downcomer as an example, and describe the present invention in detail: arrange 2 side by side in the downcomer area A downcomer of the present invention, the diameter of the outer pipe is 400 mm, the upper port of the outer pipe is flat, the diameter of the inner pipe is 150 mm, the height of the inner and outer pipes is 450 mm, the upper port of the inner pipe is set to be 150 mm higher than the upper port of the outer pipe, and on the wall of the inner pipe There are 4 rows of 8 rectangular holes with a width of 50 mm and a height of 60 mm evenly arranged along the axial direction, with a total of 32 air holes, and the angle between the tongue and the axial direction is 60 degrees; Two layers of swirl guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com