Gas-liquid separation device

A gas-liquid separation device and airflow technology, applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of increased resistance of liquid flowing through the drain hole, decreased efficiency of gas-liquid separation, and decreased separation efficiency , to achieve the effects of preventing secondary entrainment of liquid film, improving gas-liquid separation efficiency, reducing resistance and separation pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

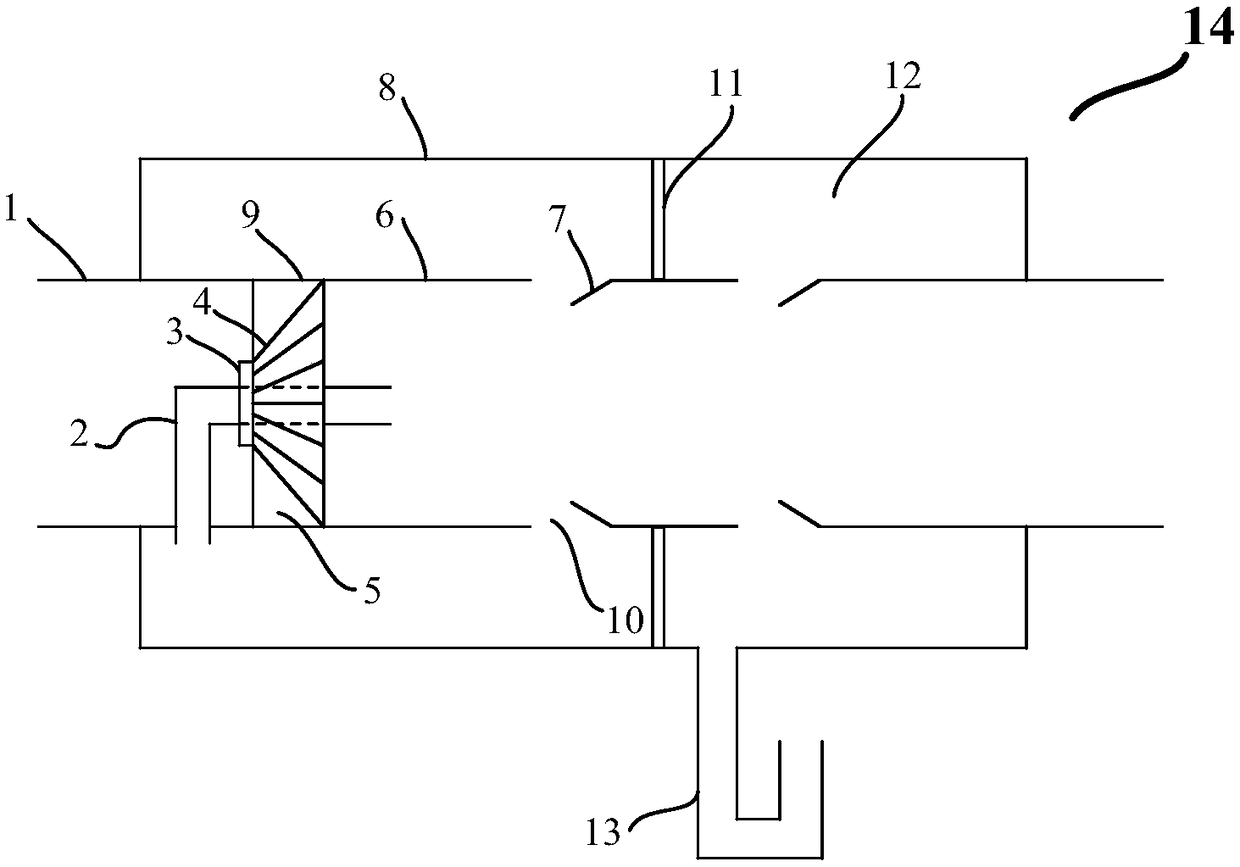

[0027] use as figure 1 The horizontally arranged gas-liquid separation device 14 shown is used for gas-liquid separation after the condensed circulating gas in the process of producing linear low density polyethylene (LLDPE). Wherein, the internal diameter of inner cylinder 6 is 600mm, is divided into 3 pipe sections, and the width of liquid separator 10 is 50mm, and the diameter expansion ratio of the second pipe section is 1.10, and the internal diameter of outer cylinder 8 is 1000mm, and the external diameter of cover cylinder 9 is 590mm, the inner diameter of the elbow 2 is 80mm, the diameter of the blind plate 3 is 200mm, the number of swirl blades 4 is 15, the thickness of the blades is 5mm, and the projection overlap ratio is -0.5.

[0028] The liquid-containing gas stream comprising hydrogen, nitrogen, methane, ethane, ethylene, hexene and isopentane at a pressure of 2.4 MPa and a temperature of 47° C. passes through the gas-liquid separation device 14 at a speed of 35...

Embodiment 2

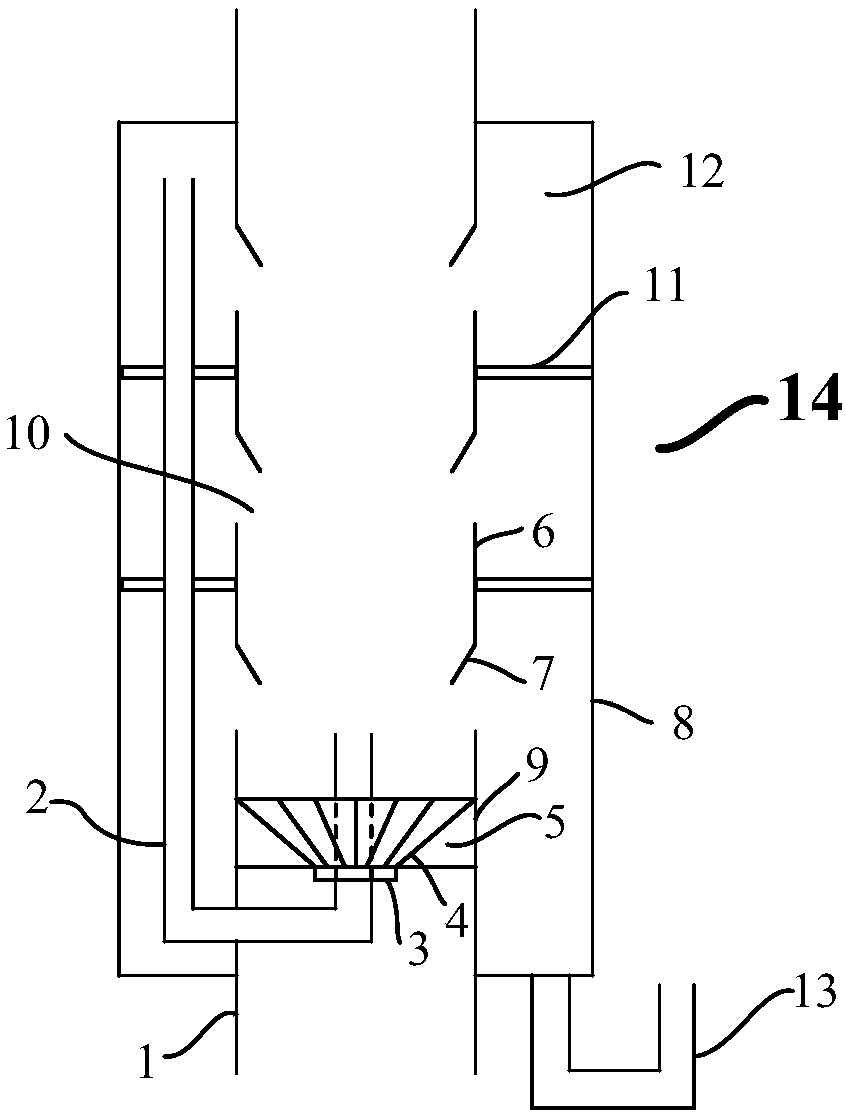

[0030] use as figure 2 The vertically arranged gas-liquid separation device 14 shown is used for gas-liquid separation after the condensed circulating gas in the process of producing linear low-density polyethylene (LLDPE). Wherein, the internal diameter of inner cylinder 6 is 700mm, is divided into 4 pipe sections, the width of liquid separator 10 is 80mm, the diameter expansion ratio of the 2nd and the 3rd pipe section is 1.05, the internal diameter of outer cylinder 8 is 1100mm, cover cylinder 9 The outer diameter of the pipe is 690mm, the inner diameter of the elbow 2 is 100mm, the diameter of the blind plate 3 is 180mm, the number of swirl blades 4 is 18, the thickness of the blades is 5mm, and the projection overlap ratio is -0.6.

[0031] A gas flow comprising hydrogen, nitrogen, methane, ethane, ethylene, hexene and isopentane with a pressure of 2.4 MPa and a temperature of 52° C. passes through the gas-liquid separation device 14 at a speed of 25 m / s. In the gas flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com