Centrifugal separation pipe, gas-liquid separation device and refrigerating system with device

A technology of gas-liquid separation device and centrifugal separation tube, which is applied in the direction of refrigerators, refrigeration components, separation methods, etc., can solve the problems of increasing the complexity of refrigeration systems, reducing the refrigeration efficiency of refrigerants, and flashing gases of refrigerants, etc., to achieve improved Gas-liquid separation efficiency, improve refrigeration efficiency, and realize the effect of gas-liquid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

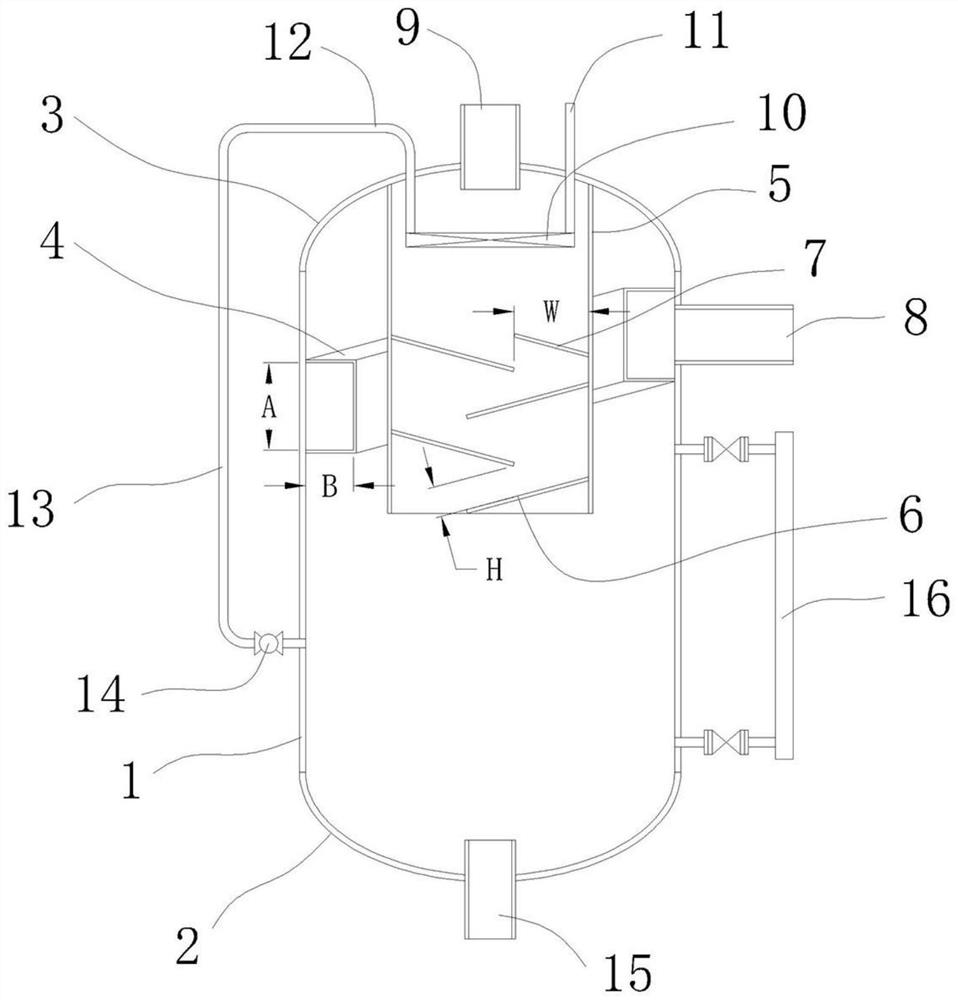

[0031] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

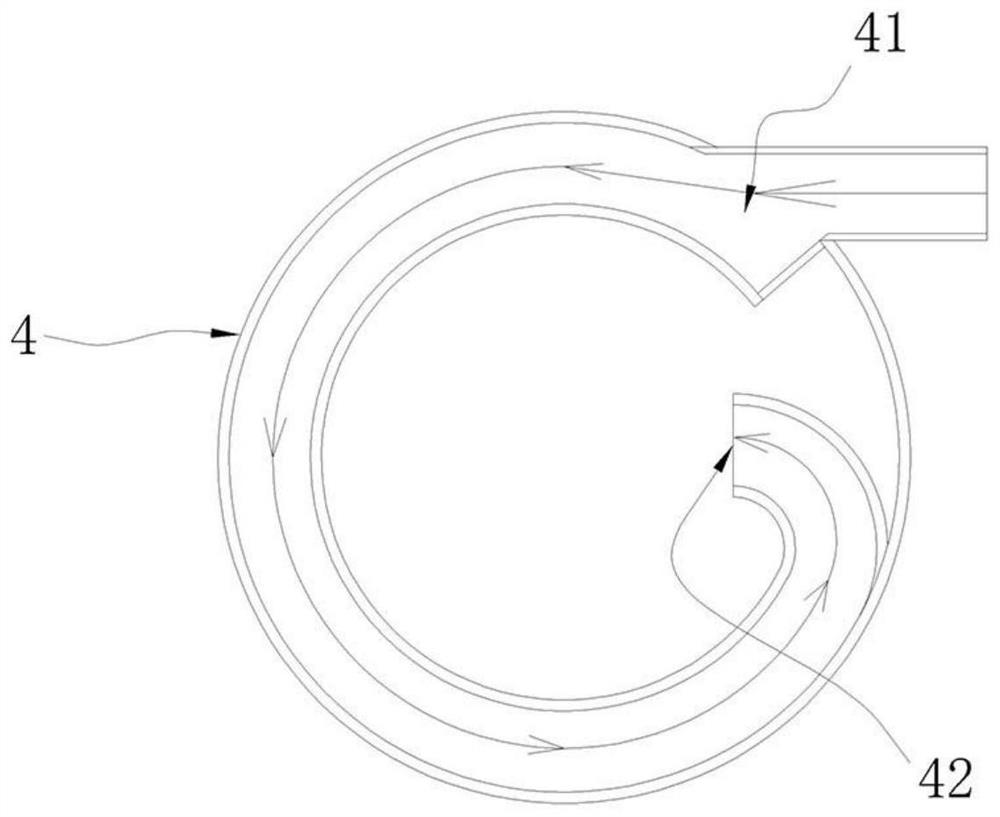

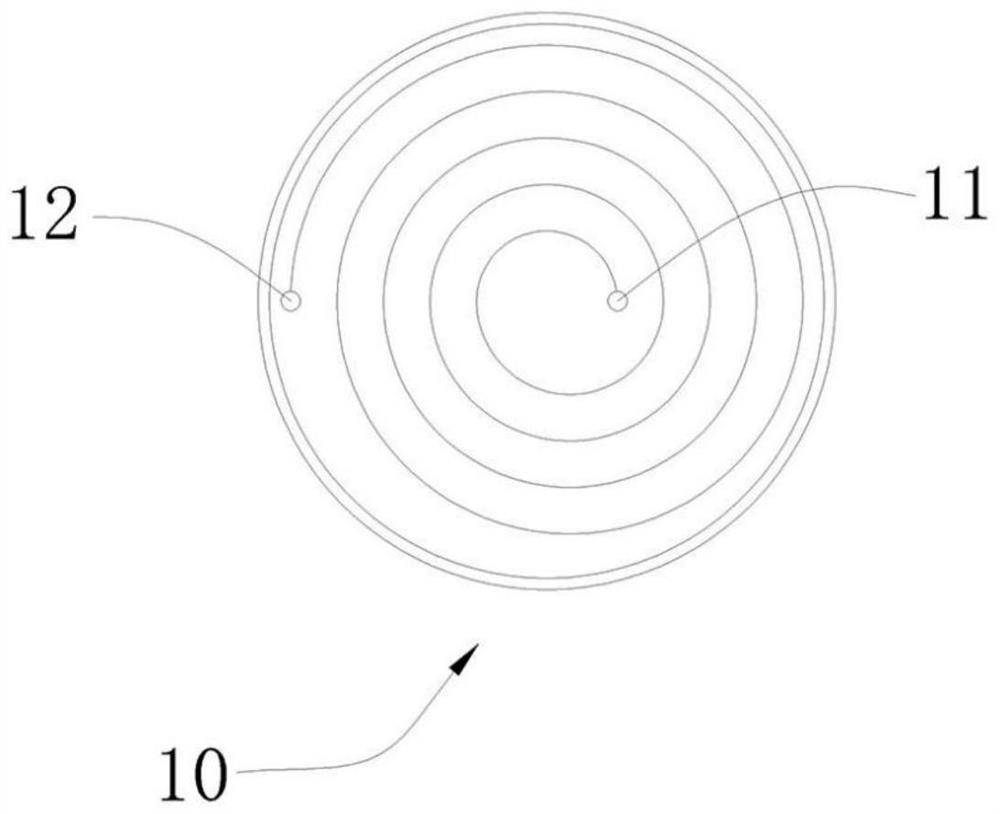

[0032] In the prior art, for example, a helical tube gas-liquid separation device disclosed in application number 201310621926.8 is provided with a helical tube coaxial with the cylinder, the top of the helical tube is a gas-liquid mixing inlet, and the bottom is a liquid outlet. The principle of the gas-liquid separation of the spiral tube is: after the gas-liquid mixed fluid to be separated enters the spiral tube from the upper end, it will rotate at a high speed under the action of pressure and flow rate. Due to the different densities of the gas and liquid, the liquid will fall faster. , the gas rises, so that the gas and liquid are separated. In this technology, the gas separated from g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com