Gas-liquid separation device and consumption reduction method for gas-liquid separation device

A gas-liquid separation device and separator technology, which is applied in separation methods, chemical instruments and methods, and general layout of liquid degassing, etc., can solve the problems of low separation efficiency and high energy consumption of oil and gas separators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

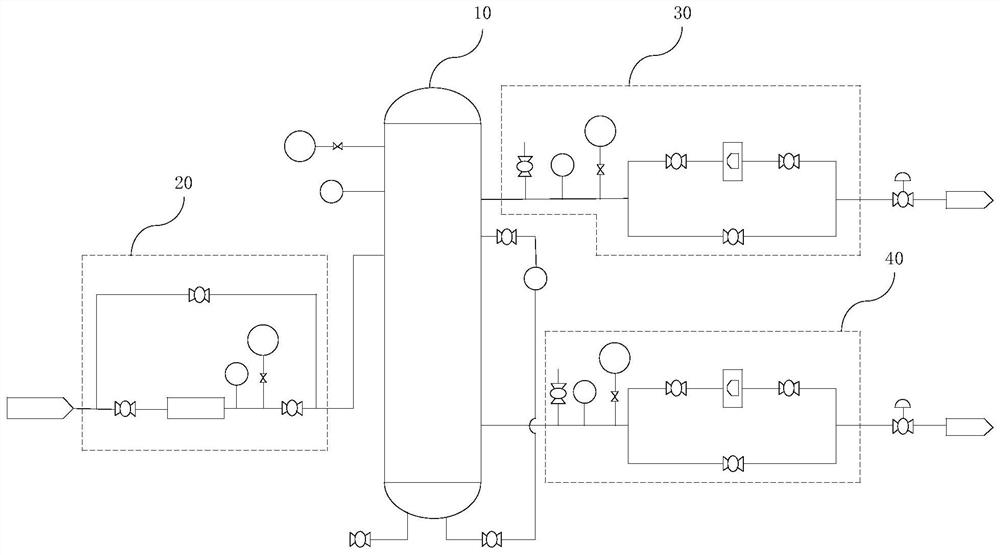

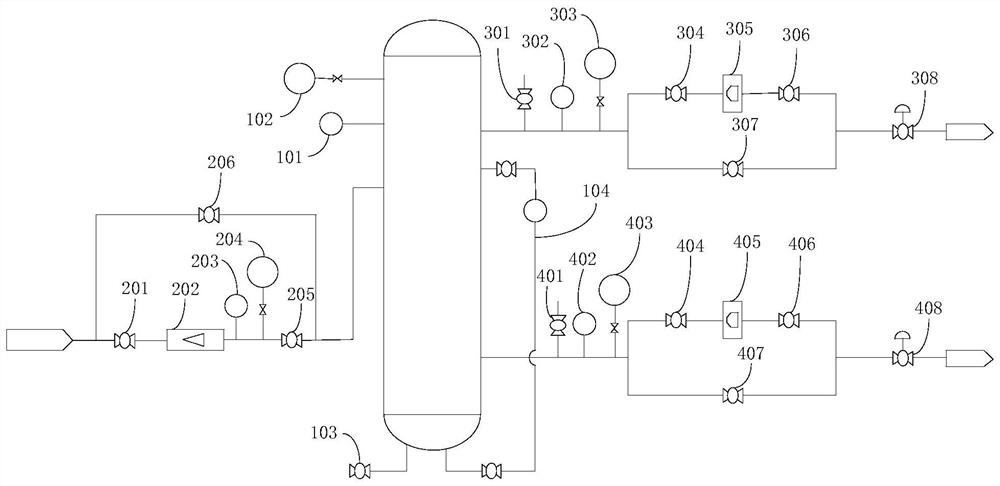

[0048] This embodiment provides a gas-liquid separation device, such as figure 1As shown, it is used to degas crude oil and physically separate the gas and liquid contained in the crude oil, including: a separator body 10, an inlet detection unit 20, a gas phase detection unit 30 and a liquid phase detection unit 40, wherein the separation The device body 10 is provided with an inlet pipeline, a gas phase outlet pipeline and a liquid phase outlet pipeline. The inlet pipeline is the inlet pipe of the separator body 10, and the inlet pipeline is mainly used to directly transport crude oil into the separator body 10. The gas phase outlet pipeline and the liquid phase outlet pipeline are the two outlet pipelines of the separator body 10. After the crude oil is separated in the separator body 10, it will form liquid and gas, and the gas will flow from the separator body 10 through the gas phase outlet pipeline. The liquid will flow out from the separator body 10 through the liquid ...

Embodiment 2

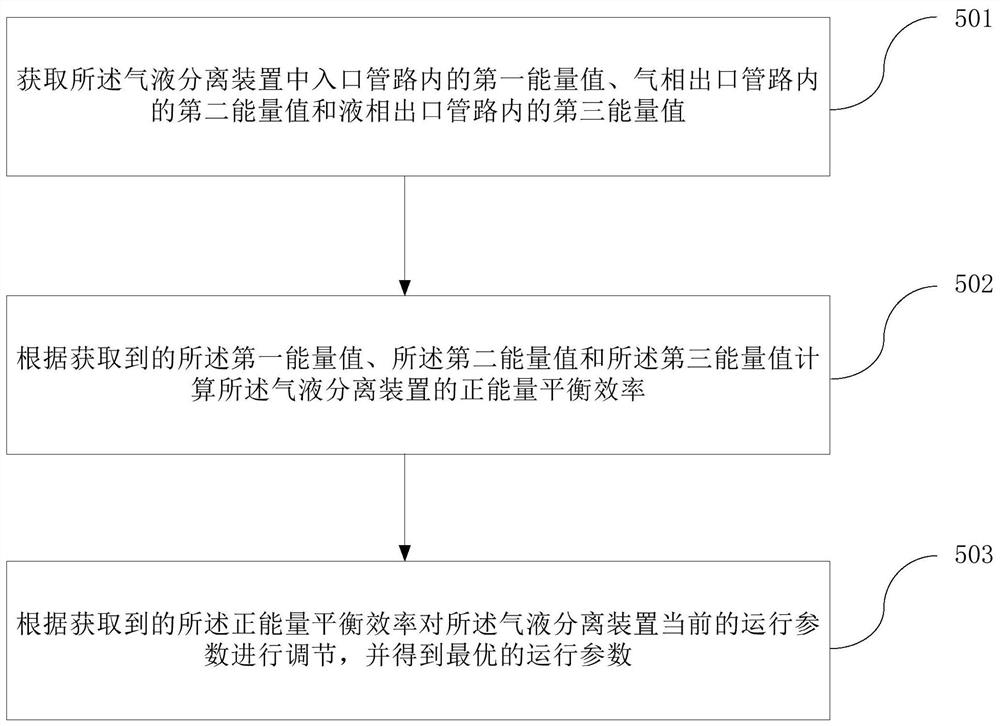

[0064] This embodiment provides a consumption reduction method for gas-liquid separation. The consumption reduction method is applied to the gas-liquid separation device provided in Embodiment 1. This consumption reduction method can adjust and optimize the operating parameters of the gas-liquid separation device to ensure separation efficiency. balance energy consumption.

[0065] A method for reducing consumption of gas-liquid separation, such as image 3 shown, including the following steps:

[0066] Step 501. Obtain the first energy value in the inlet pipeline, the second energy value in the gas phase outlet pipeline and the third energy value in the liquid phase outlet pipeline in the gas-liquid separation device.

[0067] After the crude oil is exploited, it is directly passed into the gas-liquid separation device for gas-liquid separation. The separated gas material is transported to the gas phase outlet pipe, and the separated liquid material is transported to the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com