Gas-liquid separation device for boat

A gas-liquid separation device and marine technology, applied in the field of marine power systems, can solve the problems of difficulty in adapting to the actual operation of marine power systems, complex changes in marine engine operating conditions, and increased installation difficulty due to large equipment volumes, so as to improve acoustic stealth. capacity, improve the efficiency of gas-liquid separation, and have the effect of large operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

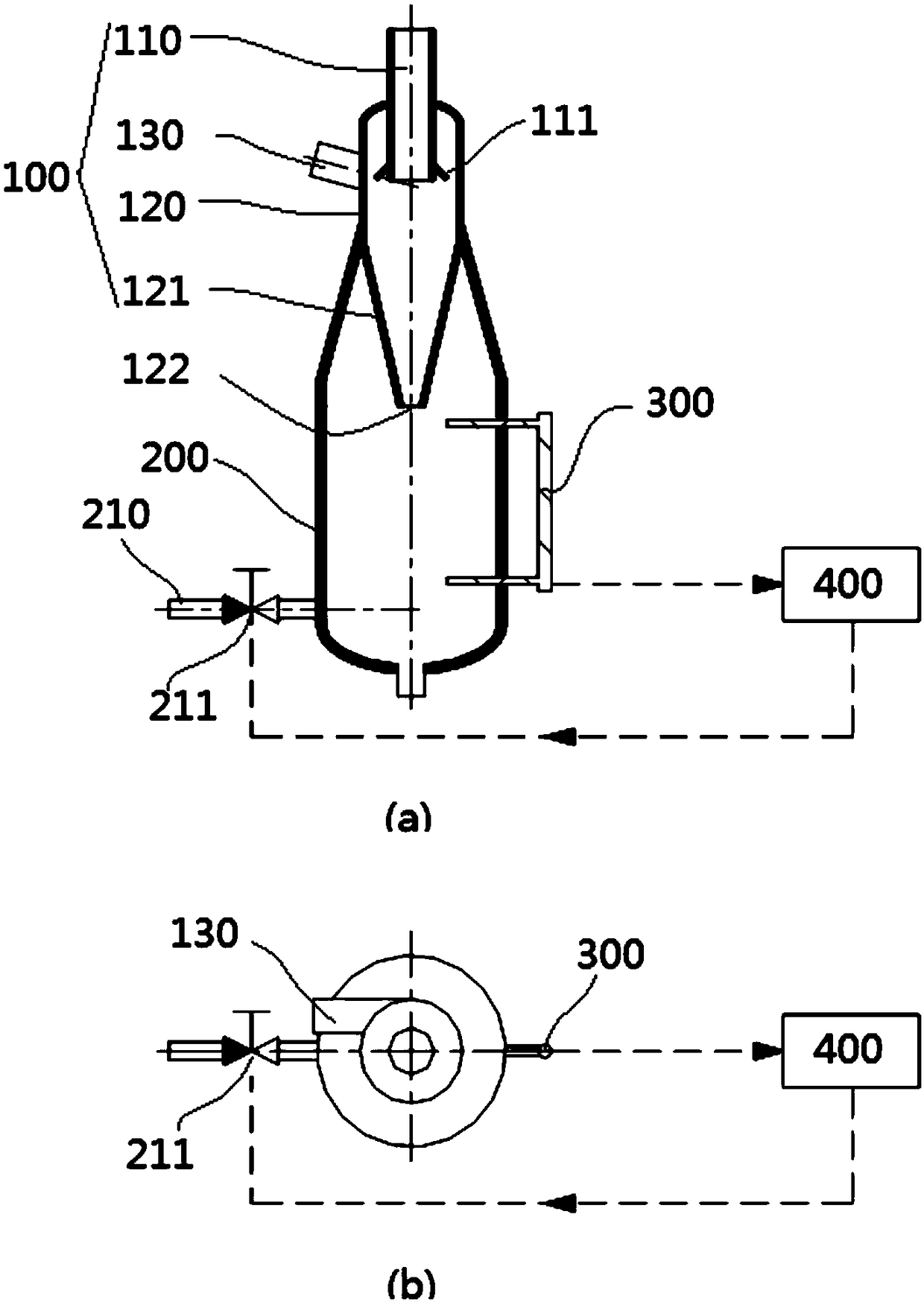

[0034] Such as figure 1 As shown, this embodiment discloses a marine gas-liquid separation device, including a gas-liquid cyclone unit 100 , a liquid storage unit 200 , a liquid level sensor 300 and a control unit 400 . (a) is the front view, (b) is the top view.

[0035] Wherein, the gas-liquid cyclone unit 100 includes an overflow pipe 110, an inlet pipe 130, and a main body, wherein the main body includes a cylindrical section 120 and a conical section 121 from top to bottom; the inlet pipe 130 communicates with the cylindrical section 120 to form a gas-liquid mixing inlet , the other end of the inlet pipe 130 communicates with the exhaust system of the marine engine, that is, the combustion product of the marine engine enters the marine gas-liquid separation device through the exhaust system, and the main component of the combustion product is CO 2 and H 2 A gas-liquid two-phase mixture of O. The upper end of the cylindrical section 120 is provided with an opening to pa...

Embodiment 2

[0040] Such as figure 1 As shown, on the basis of Embodiment 1, the upper end of the liquid storage unit 200 includes an opening to accommodate all or part of the conical section 121 inside, and the liquid storage unit 200 is integrally formed with the gas-liquid cyclone unit 100 or fixed through the opening. connect. That is, the conical section 121 is placed inside the liquid storage unit 200 through the opening, and the size of the entire device is reduced, which can be applied to a more compact installation space.

[0041] Exemplarily, a gas-liquid mixing inlet is provided on the side wall of the cylindrical section 120 , and the inlet pipe 130 is arranged tangentially to the cylindrical section 120 and is arranged obliquely downward toward the cylindrical section 120 .

[0042] The lower end of the overflow pipe 110 includes a skirt structure 111, and the height of the skirt structure 111 is approximately the same as or lower than that of the gas-liquid mixing inlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com