Polar plate for wet type electrostatic precipitator

A wet electrostatic precipitator technology, which is applied in the field of internal key components and plate structure, can solve the problems that the wet electrostatic precipitator dust collection plate does not have the water distribution function, the cleaning effect is not good, and the water film is uneven, etc., to achieve clean Excellent ash effect, low reactive power loss, uniform water film effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

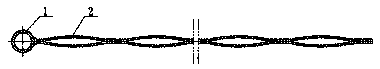

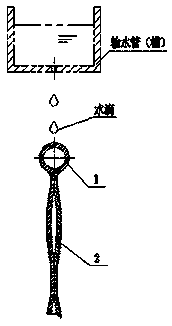

[0021] Such as figure 1 As shown, a pole plate of a wet electrostatic precipitator is composed of a flow equalizing tube (1) and a collecting plate (2). The metal or non-metallic round tube is integrated with the collecting plate (2) by welding or other means, and the cross-sectional size of the flow equalizing tube (1) is about Φ15~Φ30mm, which can be determined according to the thickness design of the collecting plate (2).

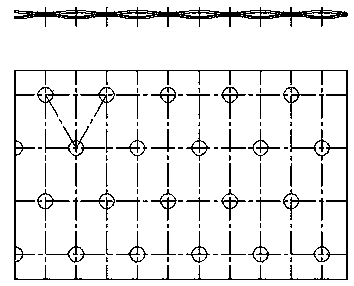

[0022] Such as figure 2 As shown, the collecting plate (2) is laser welded by two corrosion-resistant metal materials with a thickness of 0.5-1.5mm, and high-pressure gas or liquid is injected between the two layers of steel plates to make the steel plates at the non-welding points bulge and protrude. That is, a concave surface is formed at the solder joints, and a convex surface is formed at the non-solder joints. After forming, the collecting plate (2) has a double-layer symmetrical concave-convex corrugated surface structure, and its periphery is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com