Spiral dedusting demister, demisting device and absorption tower

A spiral dust removal and mist eliminator technology, which is applied in the field of spiral dust removal mist eliminators, mist removal devices and absorption towers, can solve the problems of limited dust removal effect, large amount of waste water in the desulfurization system, difficulty in dust concentration at the outlet of the absorption tower, etc., to achieve convenient Overhaul and maintenance, improve the effect of dust removal and mist removal, and improve flushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

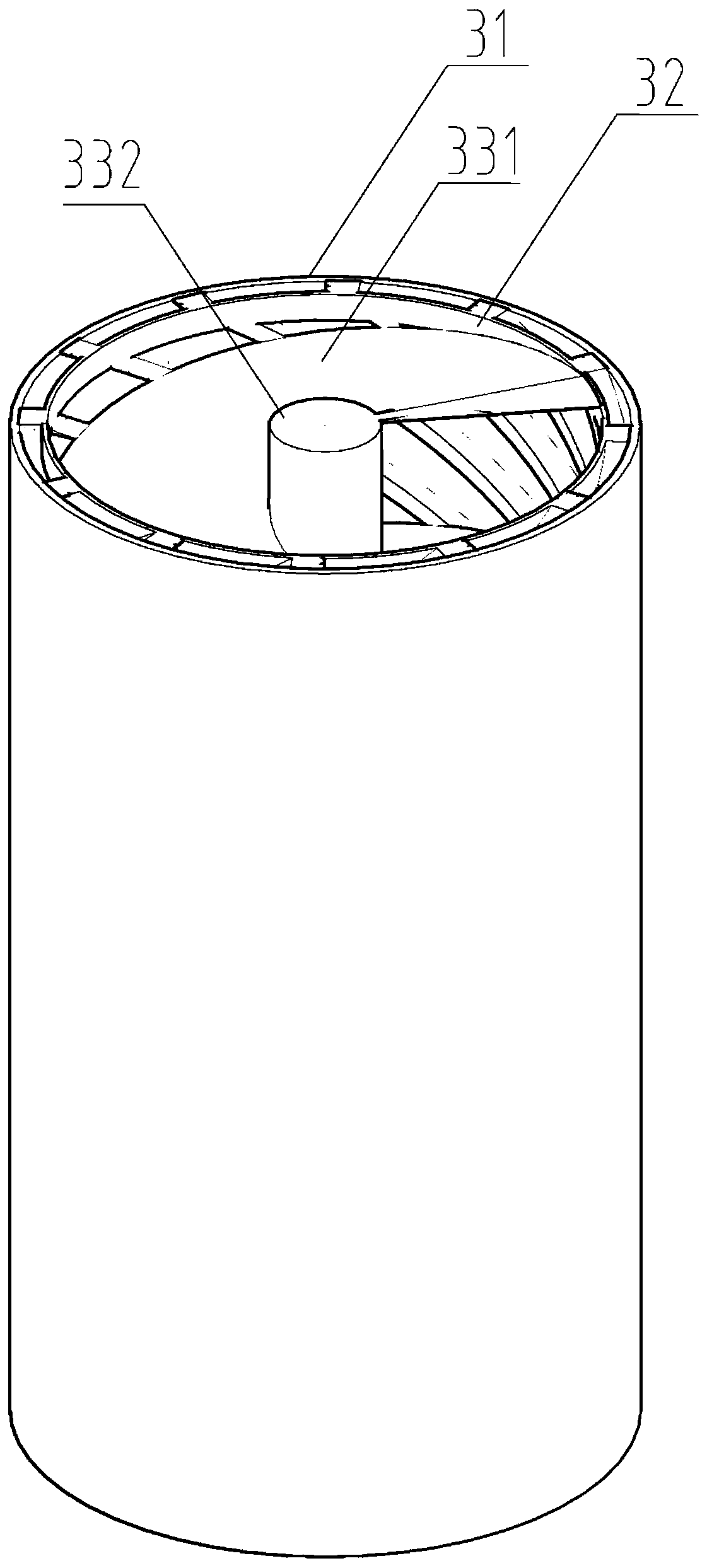

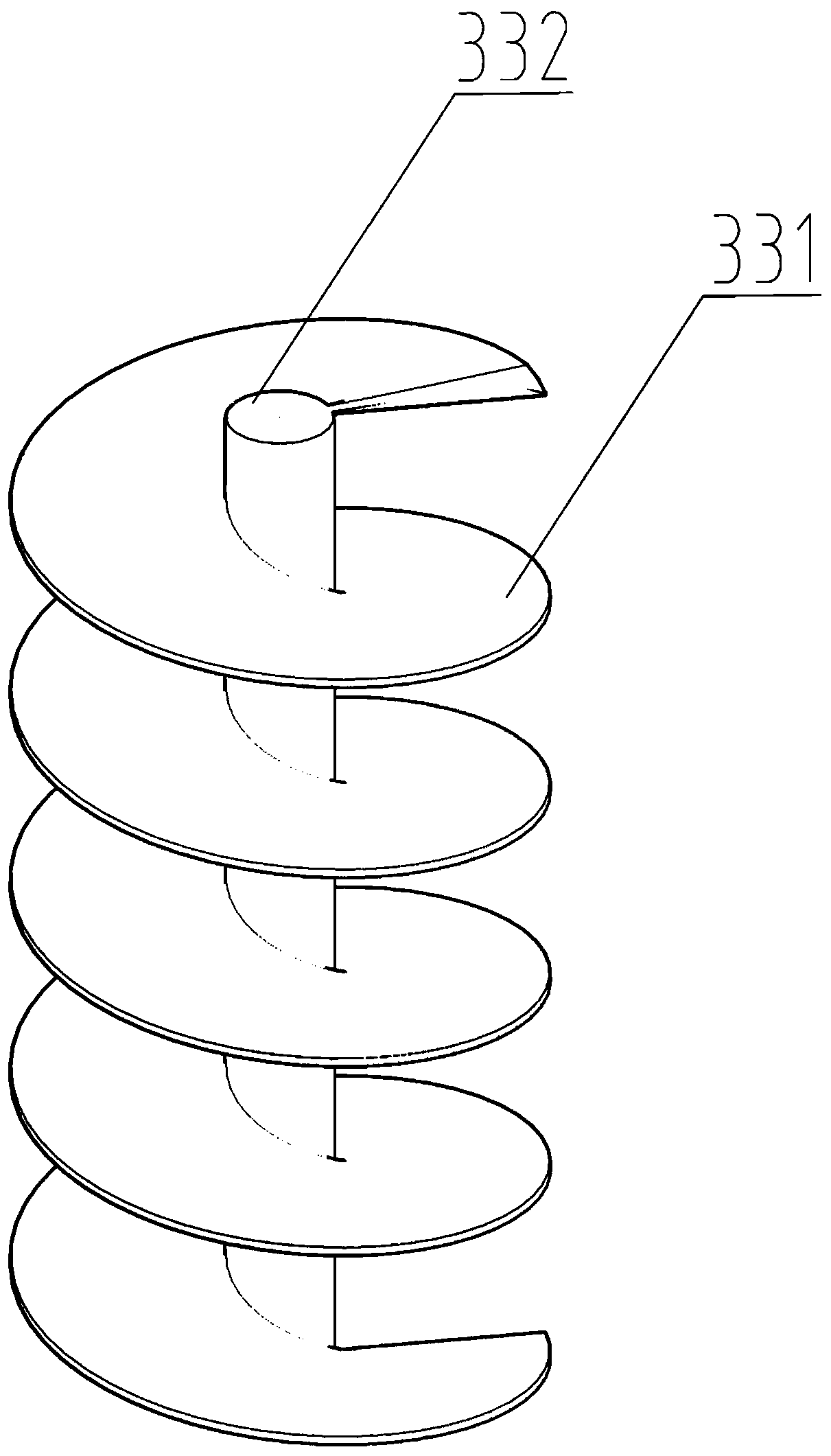

[0030] see figure 1 and figure 2 , In one embodiment, a spiral dust and mist eliminator 3 includes: a cylinder body 31, and a hollow cavity is provided in the cylinder body 31 for communicating with both ends for the flue gas to pass through. The inner spiral part 32 is detachably connected in the hollow cavity. The outer spiral portion 33 is detachably connected to the inner spiral portion 32 . Meanwhile, the helical path of the inner helical portion 32 is different from the helical path of the outer helical portion 33 .

[0031] By setting the spiral dust and mist remover 3 as a cylindrical body 31 connected at both ends, the inner threaded part is detachably connected to the inner wall surface of the cylindrical body 31, and an outer threaded part is arranged in the inner threaded part. At the same time, the helical paths of the internally threaded portion and the externally threaded portion are different. When the flue gas enters the hollow cavity of the cylinder body...

Embodiment 2

[0040] see Figure 4 , the demisting device of the present embodiment comprises a filter plate and the spiral dust and mist eliminator 3 in the above-mentioned embodiment one; the filter plate is provided with a plurality of accommodating through holes for accommodating the spiral dust and mist eliminator 3, and the spiral dust and mist eliminator 3 The demister 3 is arranged in the receiving through hole. The shape of the filter plate can be adapted to the cross-section of the absorption tower, so that it can be installed in the absorption tower and sealed, so that the flue gas can be discharged after passing through the spiral dust and mist eliminator 3. The number of accommodating through holes on the filter plate can also be set according to the required air flow and the cross-sectional area of the absorption tower.

Embodiment 3

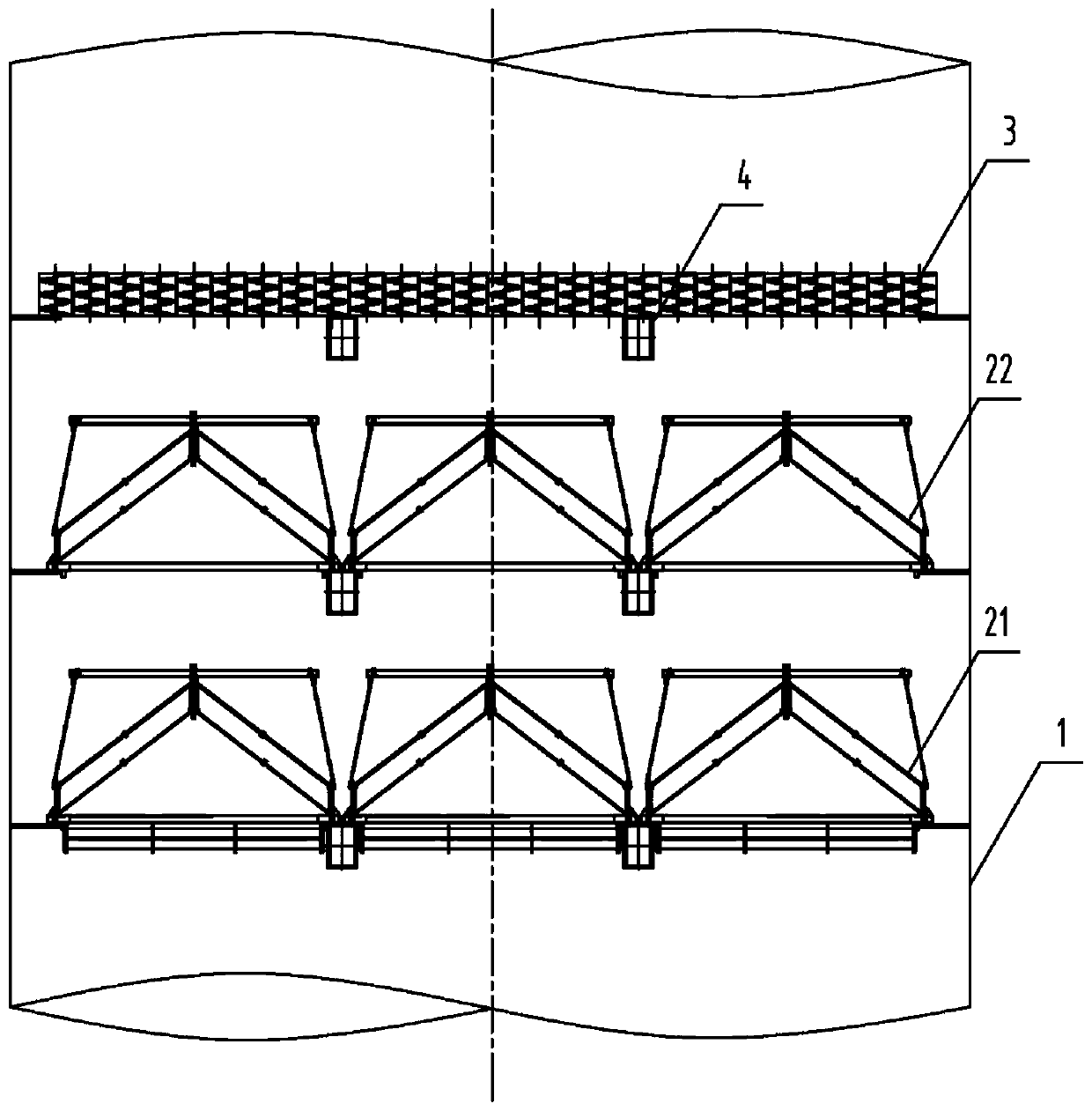

[0042] see image 3, an absorption tower 1 of this embodiment is provided with the demisting device in the second embodiment above.

[0043] When the required dust and fog removal requirements are relatively high, a primary roof type mist eliminator 21 and a secondary roof type mist eliminator 22 and at least one mist removal device can also be installed in the flue according to the flow direction of the flue gas. The demisting device is installed through the support beam 4 arranged in the absorption tower 1 .

[0044] Pre-defogging is carried out by the first-level ridge-type demister 21 and the second-level ridge-type demister 22, and then fine demisting is carried out by the demister device, so as to further improve the dust and mist removal performance of the absorption tower 1, and ensure that the absorption tower 1 Under the premise of the outlet droplet concentration, the effective removal of dust and ultra-low emission requirements are achieved, which has important en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com