Vortex-radial-acceleration dedusting and defogging device

A technology of demisting device and vortex, which is used in combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of affecting the purification effect of flue gas, unavoidable accumulation of dust particles and mist droplets and being entrained by airflow, insufficient Achieving the problems of efficient separation of dust particles and mist droplets from airflow, achieving compact structure, preventing secondary entrainment, and preventing premature low pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

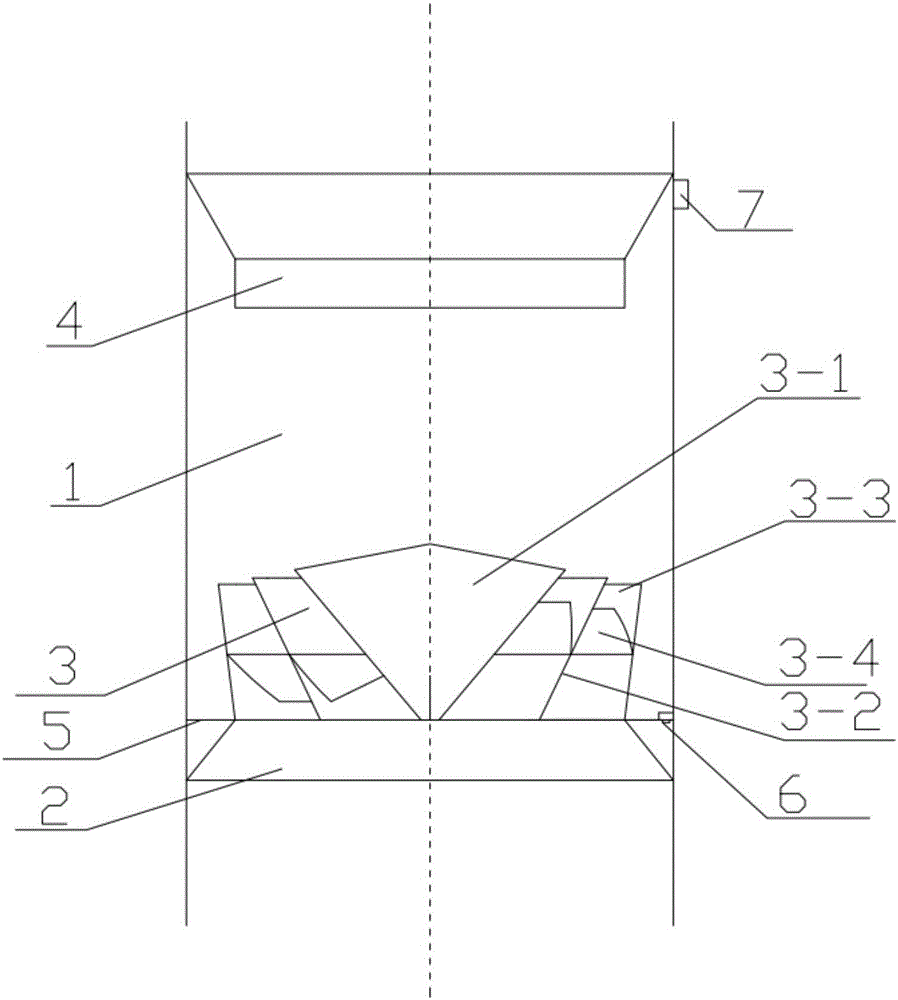

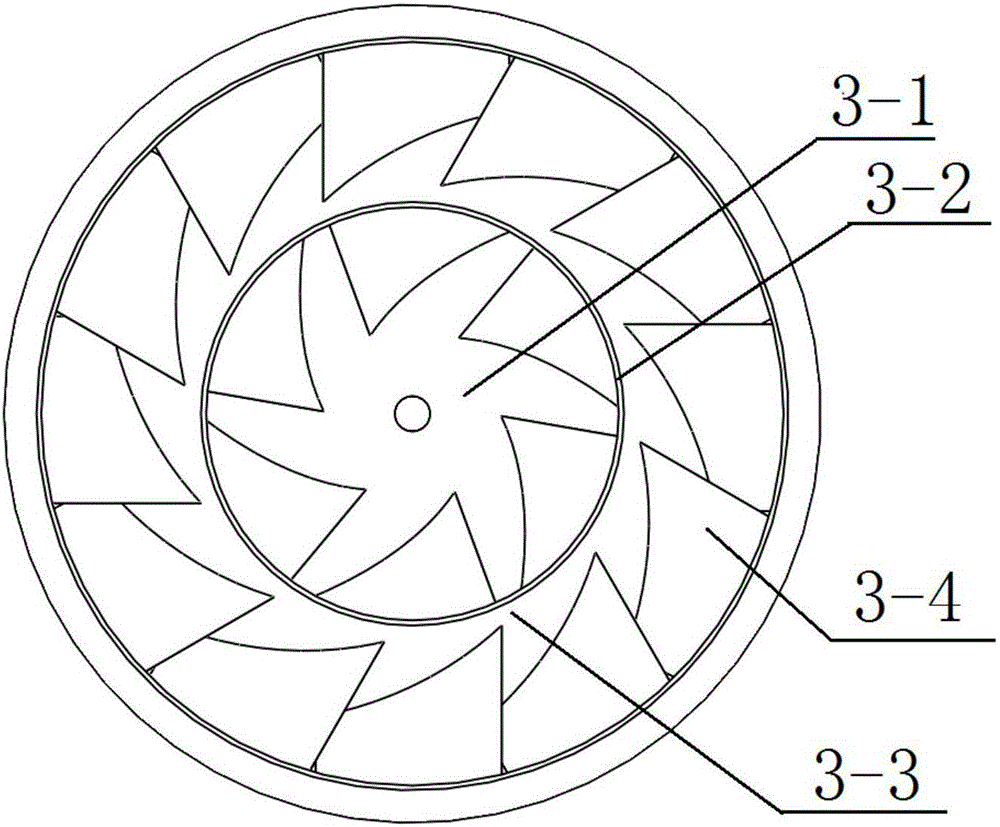

[0029] Such as Figure 1-Figure 4 As shown, in this embodiment, a vortex radial acceleration dedusting and mist removal device includes a cylinder body 1, an air inlet 2, a vortex accelerator 3, and an air outlet 4. The air inlet is arranged at the lower end of the cylinder body. The vortex accelerating body is installed on the air inlet through the support plate 5, and the air outlet is arranged at the upper end of the cylinder body; the vortex accelerating body 3 includes a central body 3-1, an expanding tube 3-2, and an annular air duct 3-3 and vortex blades 3-4, the central body 3-1 and the expander 3-2 are coaxially arranged, and both are arranged on the support plate 5 and fixedly connected with the support plate; the central body 3- 1 is a sealed cavity, the shape of which is a curved body with a large top and a small bottom. The diameter of the gradually expanding tube 3-2 continuously expands from bottom to top, showing a hollow curved body with a large top and a smal...

Embodiment 2

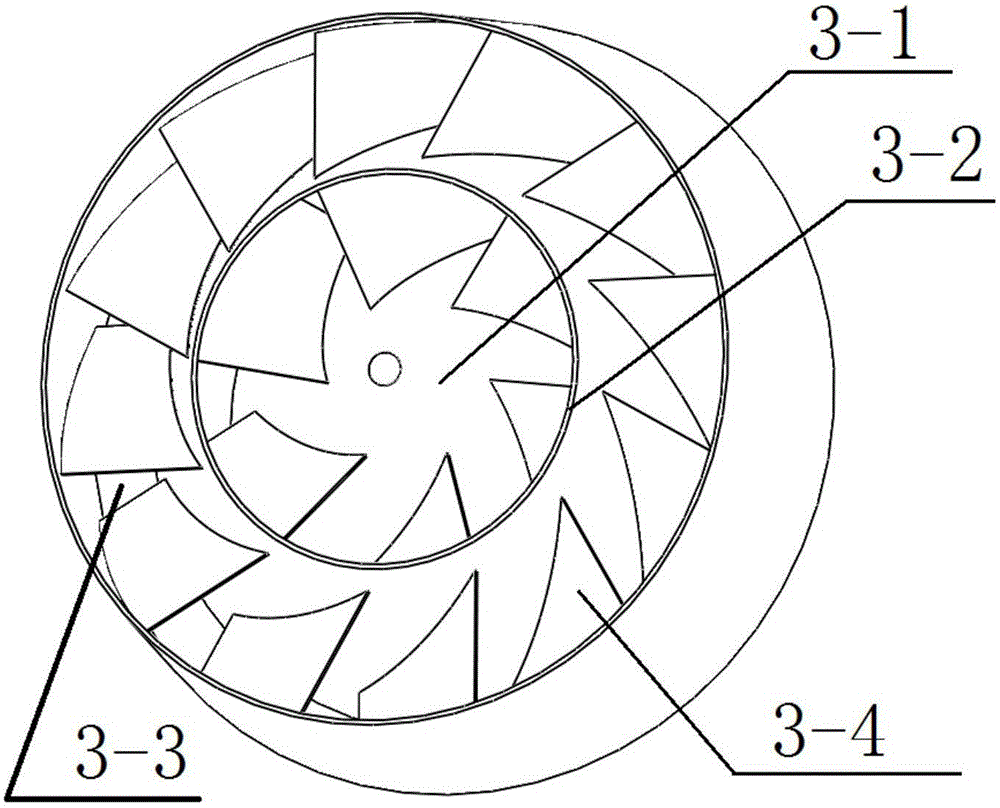

[0043] The technical solution of this embodiment is the same as that of Embodiment 1 except for the following technical features. The outer large order is arranged in sequence, and the multiple expanders are set as the first expander, the second expander...the Nth expander from the inside to the outside, and the central body and the first expander form a first ring Air duct, the first expander and the second expander form a second annular air duct...the N-1th expander and the Nth expander form the Nth annular air duct; each annular air duct is There are n swirl blades 3-4, and the swirl blades are fixedly connected with the central body or the diffuser for the air duct. In this embodiment, through the arrangement of multiple expanders, multiple annular air ducts can be formed, and n swirl blades are evenly arranged in each annular air duct, n≥3, and the swirl blades are respectively connected to the central body or the progressive The expansion pipes are fixedly connected, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com