High-temperature pyrolysis reactor for reducing dust content of oil gas

A technology of pyrolysis reactor and high-temperature pyrolysis, which is applied in gas dust removal, petroleum industry, combustible gas purification, etc., can solve the problems of system complexity, increase system resistance, increase system control, etc., to ensure dust removal efficiency and prevent The effect of cross-breathing and simplifying the difficulty of post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

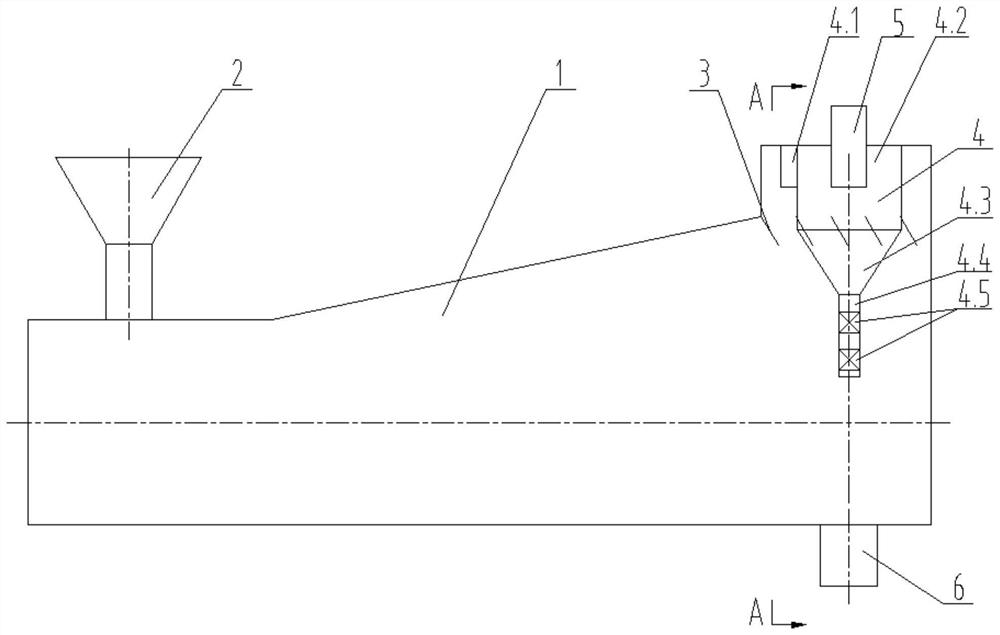

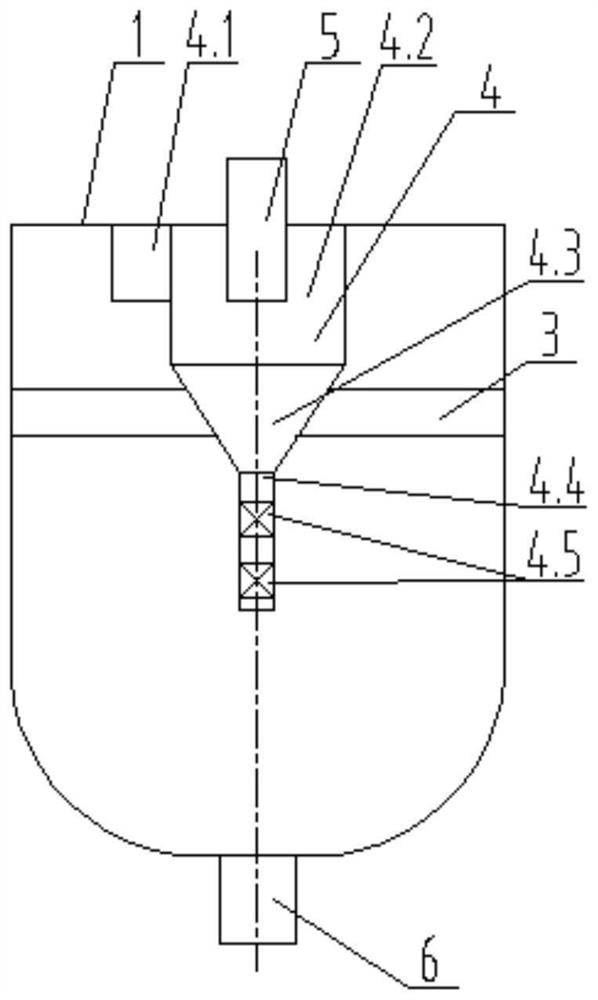

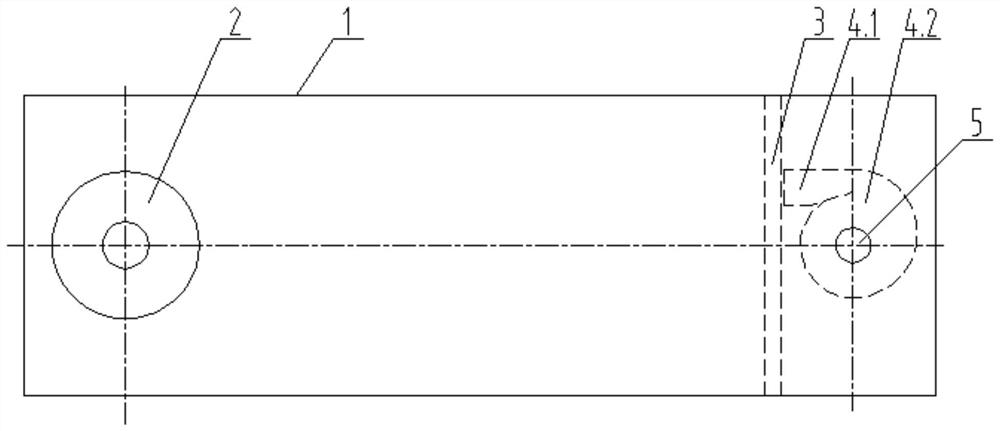

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] The present invention provides a high-temperature pyrolysis reactor for reducing the dust content of oil and gas. Mainly through the structure of the pyrolysis reactor itself, gas-phase dry dust removal is performed on the pyrolysis gas, so that it has the function of self-dust removal, so as to reduce the dust content of the pyrolysis gas outlet. , simplify the subsequent dust removal process system of pyrolysis gas, and reduce the difficulty of pyrolysis oil treatment.

[0029] like Figure 1-5 As shown, a high-temperature pyrolysis reactor for reducing the dust content of oil and gas according to the present invention includes a pyrolysis reactor shell 1, a reactor material inlet 2, a louver baffle 3, a swirl device 4, and a pyrolysis gas outlet 5. Pyrolysis solid product outlet 6. Among them, the cyclone device 4 is divided into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com