Polysulfone and preparation method thereof

A technology of polysulfone and dichlorodiphenyl sulfone, which is applied in sustainable manufacturing/processing, climate sustainability, chemical industry, etc., can solve the problems of unsuitable material environmental protection requirements, catalytic effect, low catalytic efficiency, etc. , to achieve the effects of excellent appearance, improved catalytic efficiency, and easy control of molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 57mmol sodium hydroxide / 12mL water, 20mmol polyethylene glycol-4 / 20mL tetrahydrofuran successively into a 100mL four-necked flask with an ice-salt bath, stir for 1.5h, slowly drop 37mmol4-methylbenzenesulfonyl chloride / 20mL tetrahydrofuran Into the system (about 2h), react below 5°C for 2.5h. Pour the reaction solution into ice water, add a few drops of 1M dilute hydrochloric acid, extract with dichloromethane, wash the organic phase with water and saturated brine, and dry over anhydrous magnesium sulfate. Filter and remove the organic solvent to obtain tetraethylene glycol di-p-toluenesulfonate.

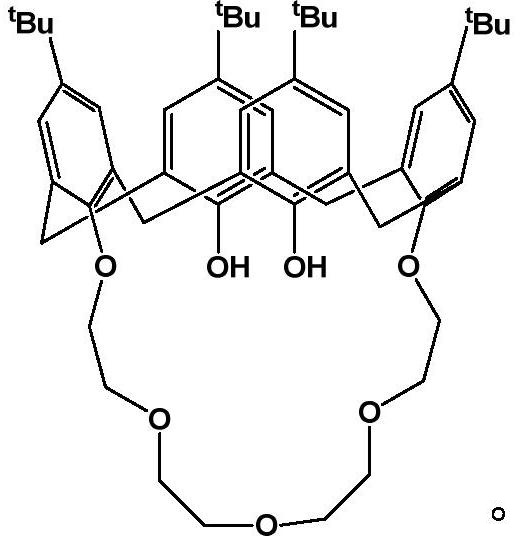

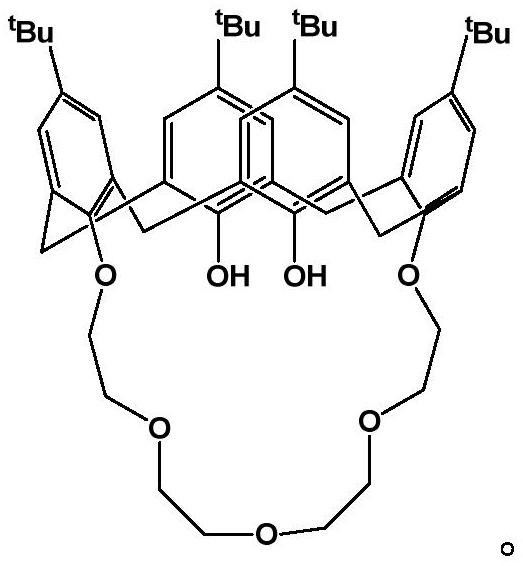

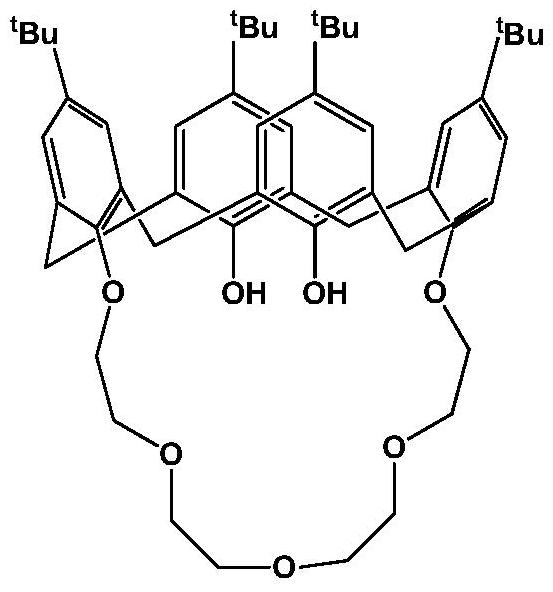

[0039]Under the protection of nitrogen, 300 mL of acetonitrile, 6.75 mmol of p-tert-butylcalix[4]arene, 7.64 mmol of tetraethylene glycol di-p-toluenesulfonate and 7.64 mmol of potassium carbonate were successively added into a three-necked flask, and the reaction was stirred and refluxed at 80°C for 24 hours. Filtration, the filtrate was evaporated to remove the solvent...

Embodiment 2

[0042] Refer to Example 1 for the preparation process of the catalyst p-tert-butylcalix[4]-1,3-crown-5.

[0043] In a four-necked reaction flask with oil bath heating, stirrer, water separator and condenser, add 0.1 mol bisphenol S, 0.1 mol sodium carbonate, 0.098 mol 4,4'-dichlorobis Phenyl sulfone, 0.455g p-tert-butylcalix[4]-1,3-crown-5, 409.68g N,N-dimethylformamide, stir with nitrogen for 0.5h, and raise the temperature of the oil bath to 170 °C (system temperature 153 °C), 125 g of N,N-dimethylformamide was distilled off, and the reaction was continued for 3 h to obtain a yellow viscous polysulfone solution. Methyl chloride gas (gas flow rate: 1 L / min) was introduced into the system for capping, while the temperature of the oil bath was lowered to 150° C., and the reaction was stirred for 10 min. Dilute the reaction solution to 10% solid content, filter to remove salt, and precipitate in methanol to obtain a white flocculent solid, which is boiled in water for many time...

Embodiment 3

[0045] Refer to Example 1 for the preparation process of the catalyst p-tert-butylcalix[4]-1,3-crown-5.

[0046] 1mol bisphenol A, 2mol potassium carbonate, 0.95mol 4,4'-dichlorodiphenyl sulfone, 42.04g p-tert-butylcalix[4]-1,3-crown-5, 0.98kg sulfolane, one-time Put it into a reaction kettle equipped with temperature control, stirring and reflux water separation device, purge with nitrogen for 0.5h, raise the temperature of the reaction kettle to 300°C (system temperature 285°C), evaporate 120g of sulfolane, and continue the reaction for 10h to obtain a yellow viscous Condensed polysulfone solution. Methyl chloride gas was introduced into the system (gas flow rate 1 L / min) for capping, while the temperature of the oil bath was lowered to 150° C., and the reaction was stirred for 100 minh. Dilute the reaction solution to 10% solid content, filter to remove salt, and precipitate in ethanol to obtain a white flocculent solid, which is boiled in water for many times, filtered, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com