Electrochemical in-situ decontamination of radioactive contaminants on metal surfaces

A metal surface and electrochemical technology, applied in the direction of electrolytic components, electrolytic process, etc., can solve the problems of inconvenient maintenance and use, high decontamination cost and complexity, etc., and achieve convenient use and maintenance, high decontamination precision and decontamination effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

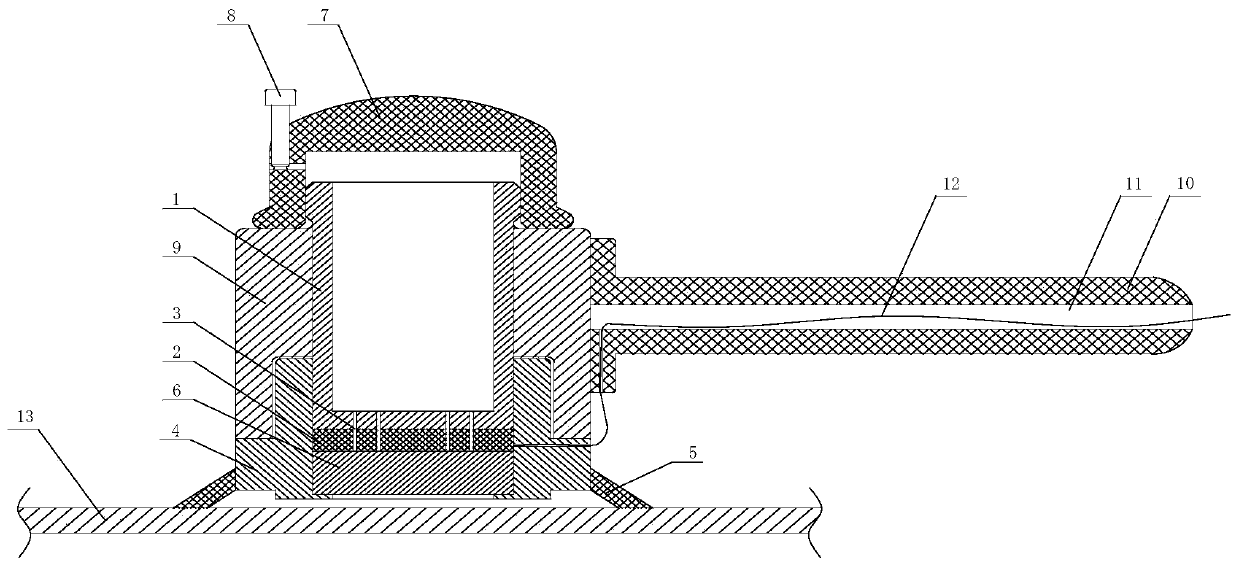

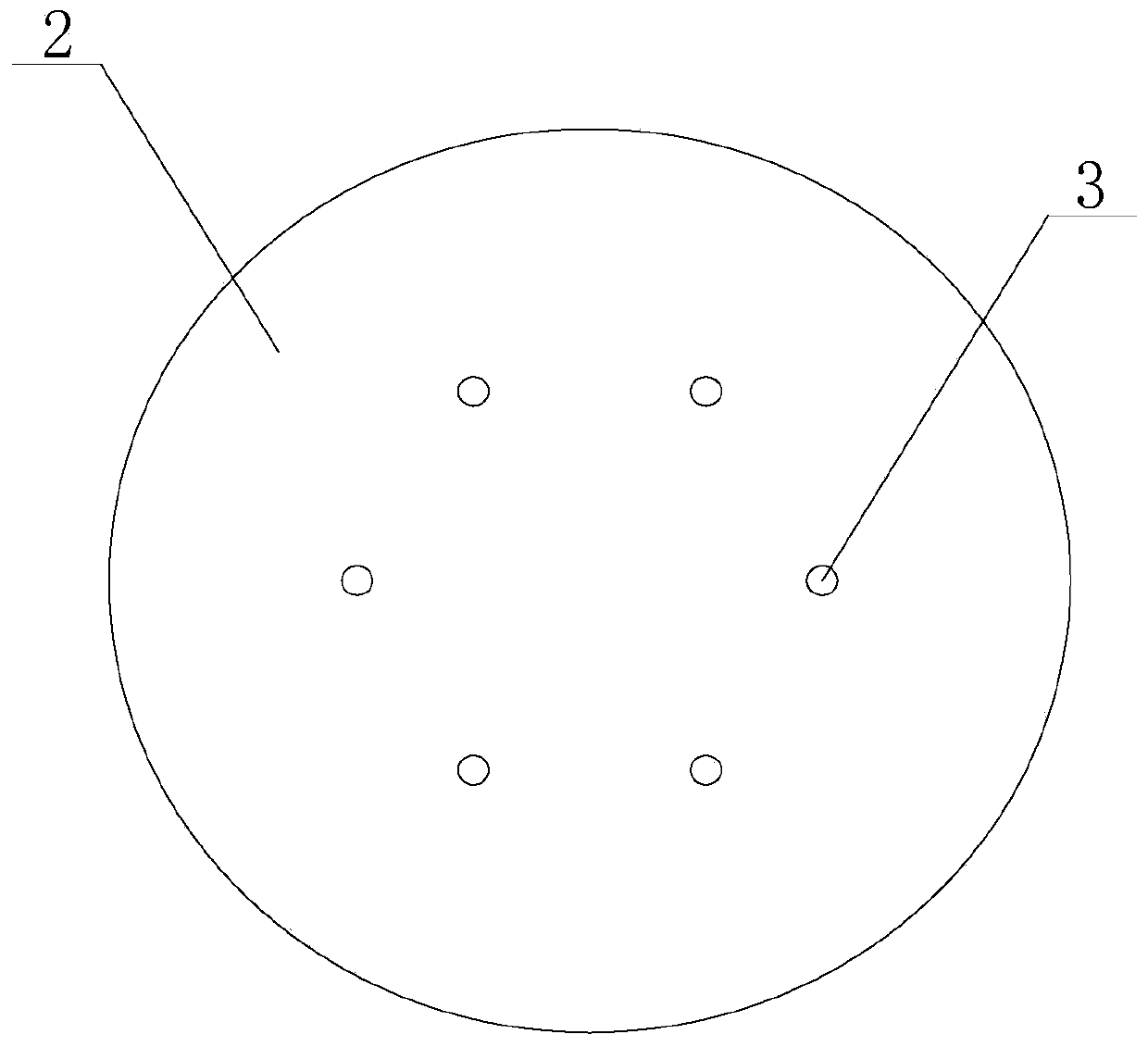

[0056] Such as Figure 1 to Figure 3 The embodiment shown, the electrochemical in-situ decontamination method of radioactive pollutants on the metal surface, the method uses an electrochemical decontamination system, and the electrochemical decontamination system includes a DC stabilized voltage power supply, an anode metal clip and a portable electrochemical cathode device, The portable electrochemical cathode device includes a liquid storage tank 1, a cathode plate 2 is installed below the liquid storage tank 1, a lead 12 is connected to the cathode plate 2, a through hole 3 is arranged at the bottom of the liquid storage tank 1, and the bottom of the through hole 3 is sequentially Through the liquid storage tank 1 and the cathode plate 2; the outside of the liquid storage tank 1 is detachably connected to an anode contactor 4, and the anode contactor 4 is provided with a housing chamber for accommodating the cathode plate 2, and the housing chamber is also A filling pad 6 l...

Embodiment 2

[0066] On the basis of Embodiment 1, the portable electrochemical cathode device also includes a top cover 7 positioned above the liquid storage tank 1, the top cover 7 is provided with an adjustment through hole, and the adjustment through hole communicates with the inner space and the outer space of the top cover 7, The top cover 7 is provided with an adjusting bolt 8 and an adjusting screw hole matching the adjusting bolt 8, and the adjusting screw hole communicates with the adjusting through hole; the bottom of the adjusting bolt 8 is provided with a gasket; the outer side of the liquid storage tank 1 A housing 9 located above the anode contactor 4 is sheathed, and a handle 10 is connected to the housing 9 , and a wiring groove 11 is arranged in the handle 10 .

[0067] Through the top cover 7, the adjustment through hole, the adjustment bolt 8, and the adjustment screw hole, the user can adjust the penetration speed of the electrolyte according to actual needs during opera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com