Recirculating fluidized bed boiler

A circulating fluidized bed and boiler technology, which is applied to fluidized bed combustion equipment, fuel burning in a molten state, lighting and heating equipment, etc. Large area, the effect of solving central hypoxia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

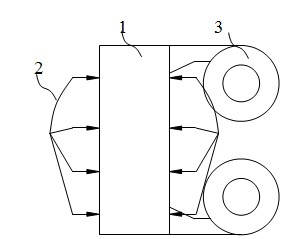

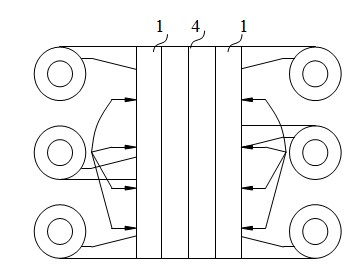

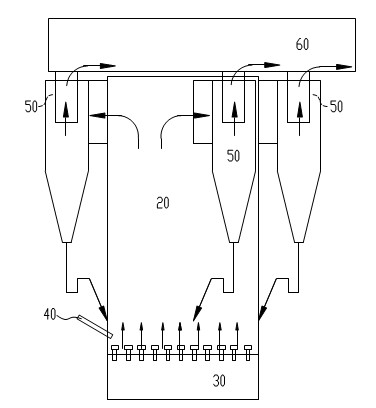

[0026] Specific embodiments of the present invention, such as image 3 and Figure 4 As shown, a circulating fluidized bed boiler includes a furnace and auxiliary equipment, wherein the furnace includes an inner wall 22 and an outer wall 21, the outer wall 21 surrounds the inner wall 22, and the annular space 20 between the inner wall and the outer wall forms an annular furnace interior. Boiler auxiliary equipment includes means 30 for introducing fluidizing air into the furnace connected to the annular furnace, means 40 for feeding fuel or other materials into the furnace, means for separating flue gases and solid materials 50, and removing flue gases from separator means The pipeline 60 and these auxiliary equipment are basically the same as the prior art, and fluidization and combustion reactions occur in the annular furnace. The process of the fluidization combustion reaction is basically the same as the disclosed circulating fluidized bed boiler process. The annular furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com