Housing structure of socket electric connector

A technology of electrical connector and shell structure, which is applied in the direction of connection, installation of connection parts, parts of connection devices, etc., can solve problems such as radio frequency interference, electromagnetic wave leakage, electromagnetic interference, etc., to slow down electromagnetic interference and radio frequency interference, reduce The effect of grounding resistance and strengthening holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

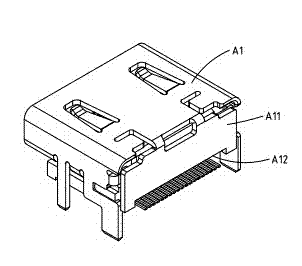

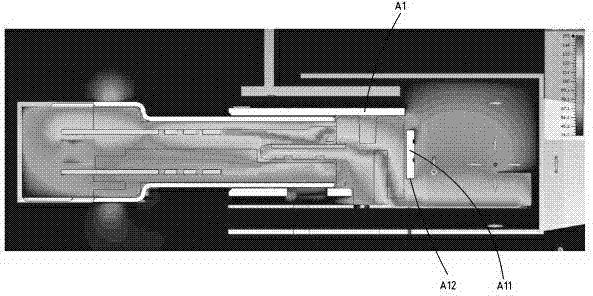

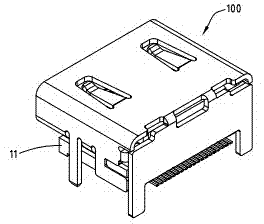

[0041] refer to image 3 , Figure 4 and Figure 5 , is an embodiment of the socket electrical connector 100 of the present invention, image 3 is a schematic diagram of the appearance, Figure 4 For the decomposition diagram, Figure 5 Schematic diagram for EMI analysis. Here, the socket electrical connector 100 is an HDMI connection interface standard, but not limited thereto. In some embodiments, the electrical receptacle connector 100 can be a micro-USB (Type-C) connection interface specification (such as Image 6 shown). In this embodiment, the socket electrical connector 100 includes an insulating body 11 , a plurality of terminals 21 and a shielding shell 31 .

[0042] refer to Figure 4 and Figure 5 , the insulating body 11 is a flat and long board, and the insulating body 11 includes a base 111 and a tongue. The plurality of terminals 21 are located on the insulating body 11 , and the plurality of terminals 21 include a plurality of welding feet 211 exposed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com