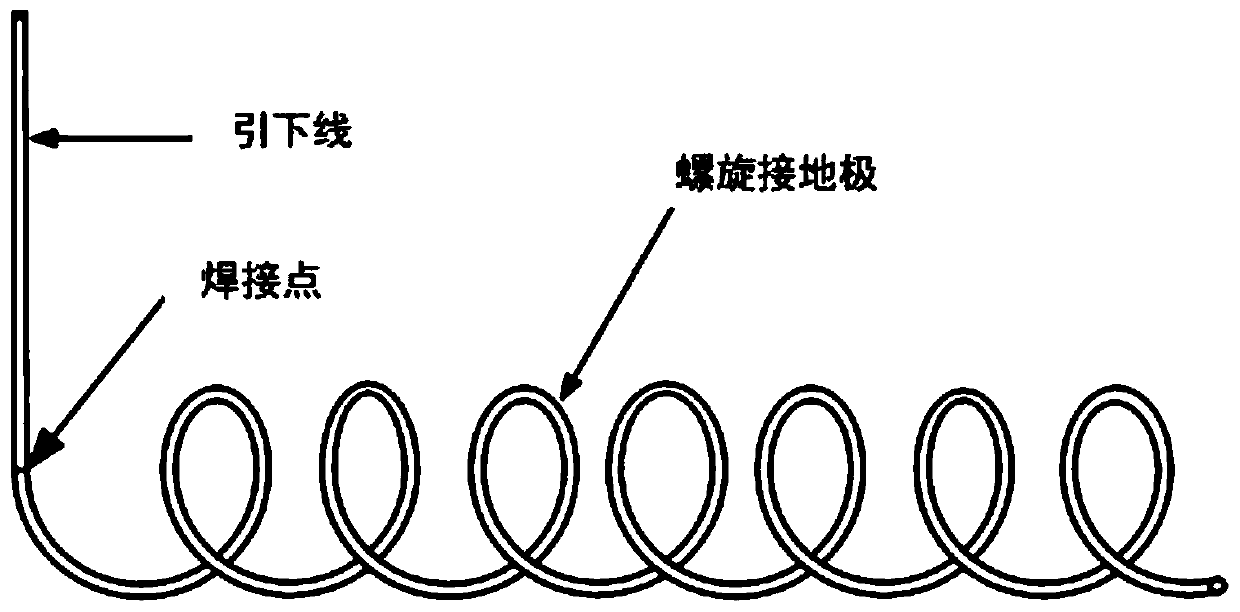

Spiral grounding electrode size parameter design method suitable for complex environment area

A complex environment, parameter design technology, applied in the field of spiral ground electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

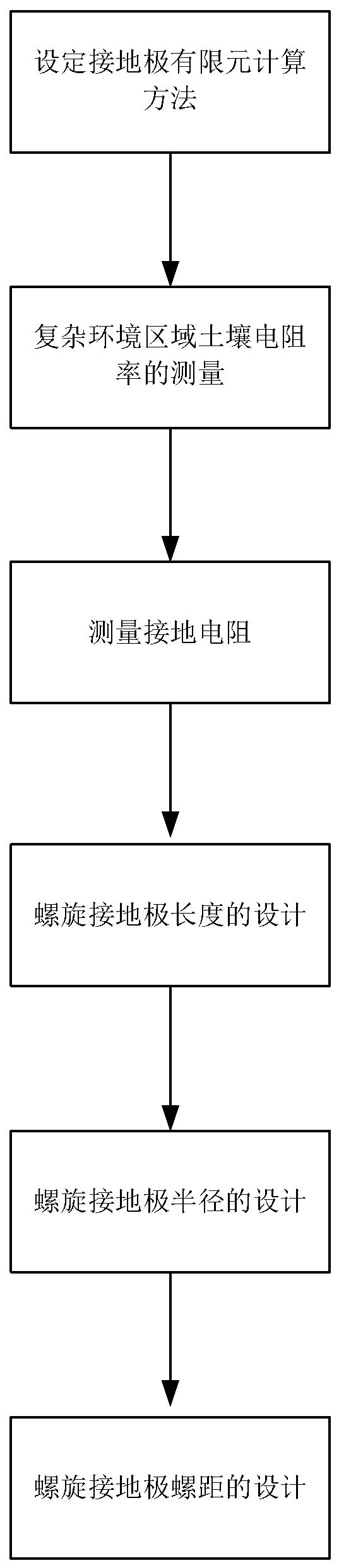

[0102] like figure 2 As shown in the present invention, a method for designing the size parameters of the spiral ground electrode suitable for complex environmental areas includes the following steps:

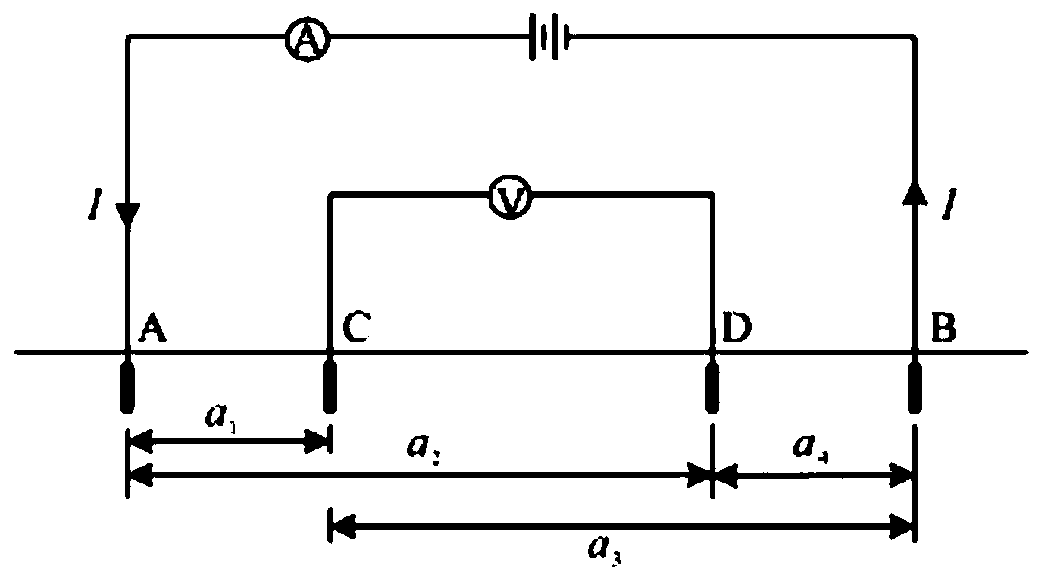

[0103] The first step is to set the finite element calculation method of the ground electrode. The finite element method is the most widely used in the numerical calculation of electromagnetic fields. The traditional finite element method is based on the variational principle, transforming the boundary value problem to be solved into the corresponding variational problem, and then using subdivision interpolation to convert the variational problem Discretization of extremum problems for ordinary multivariate functions. Here, the fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com