Grounding electrode of anti-corrosion and adjustable grounding resistor

A grounding resistance and grounding electrode technology, applied in the field of grounding electrodes, can solve the problems of manpower and material resources, the corrosiveness of the grounding network cable, and the inability to maintain the stable operation of the grounding resistance for a long time. method convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

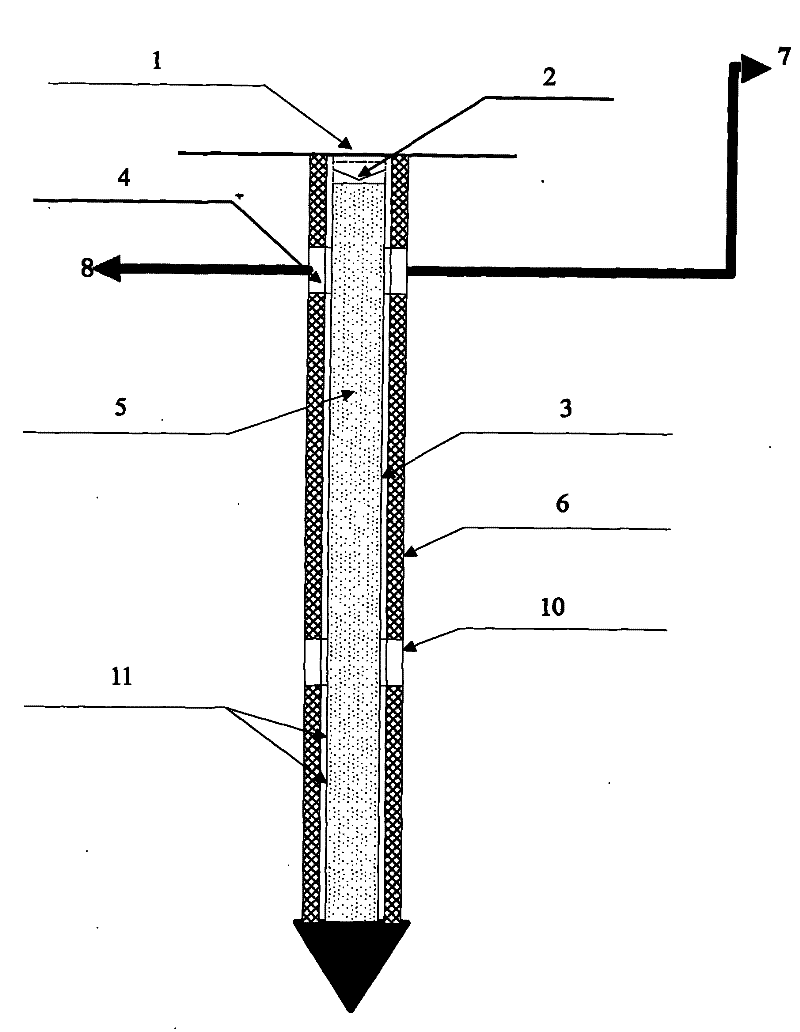

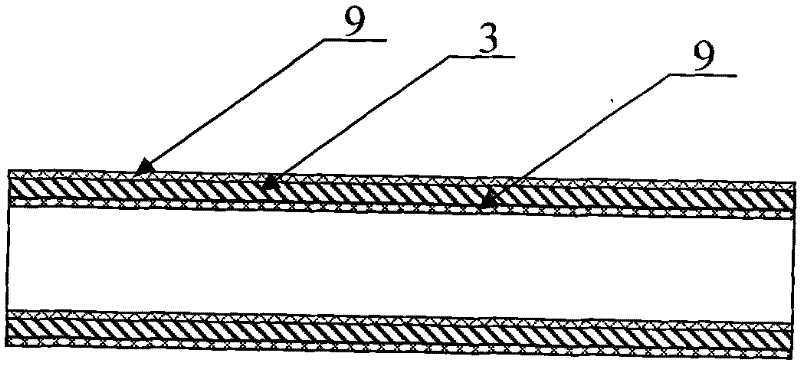

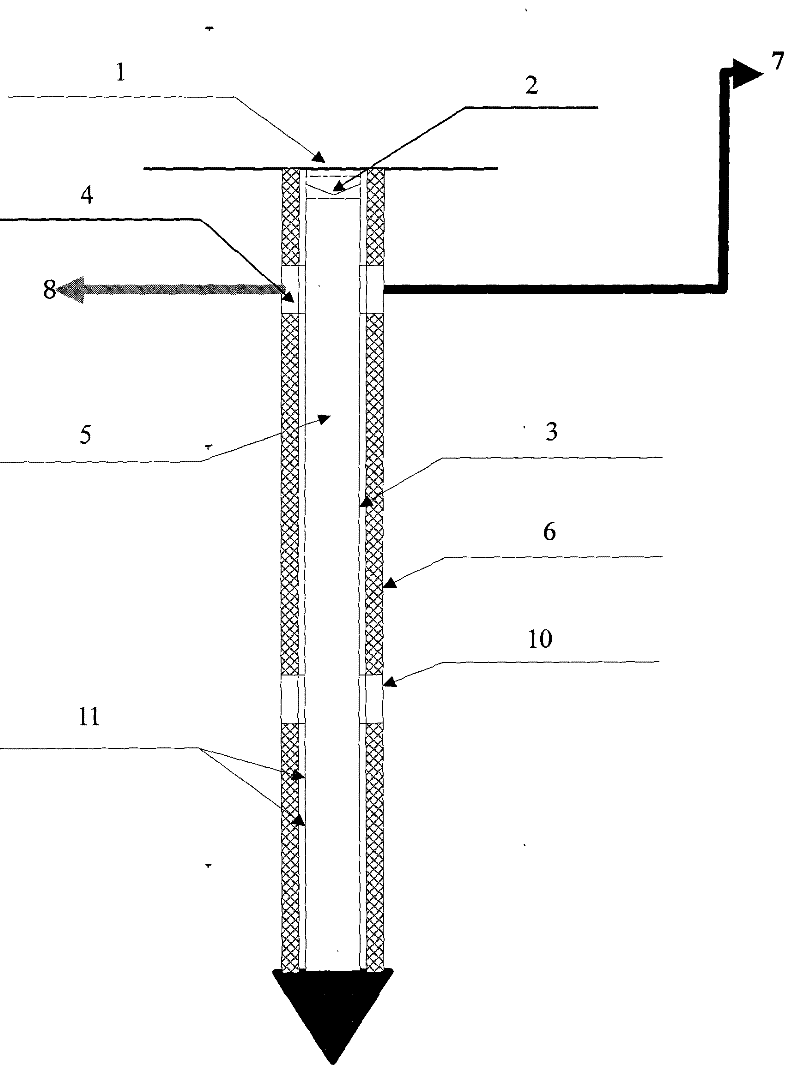

[0024] As shown in the accompanying drawings, the anti-corrosion, grounding electrode with adjustable grounding resistance of the present invention includes a thick-walled seamless steel pipe 3 as the main body of the grounding electrode. The conductive film 9, the lower end of the steel pipe 3 is provided with a head for easy insertion into the earth, the top of the steel pipe is provided with an openable filling port 1, the wall of the steel pipe 3 is provided with an electrolyte release hole 11, and the steel pipe is filled with a water-absorbing and water-retaining hole. The inner filler 5 can also be called a water-retaining and drag-reducing agent. There is a dust-proof and sundry-proof plug 2 in the steel pipe at the upper end of the inner filler 5. It can be opened at any time by using a special tool, so as to add the inner filler, that is, a water-retaining and drag-reducing agent. 3. There is an outer filler 6 that is conductive, non-corrosive, and has good water perm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com