Novel graphite composite grounding material and preparation method thereof

A composite grounding and graphite technology, which is applied in the direction of connecting contact materials, contact manufacturing, etc., to achieve the effect of simple method, high density and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

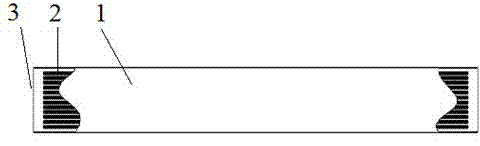

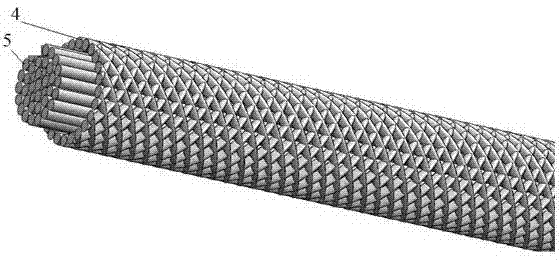

[0066] The composite graphite has a width of 20mm and a thickness of 0.22mm, and is twisted to obtain a single-strand composite graphite wire, and the tension of the single-strand composite graphite wire is 9N. 13 glass fibers impregnated in water-soluble acrylic resin are compounded in the composite graphite ribbon. With 48 composite graphite wires as the inner core of the composite graphite wire, 24 composite graphite wires are braided outside the inner core of the composite graphite wire by a braiding machine to obtain a composite graphite wire braided layer, and a graphite wire with a diameter of about 24 mm is obtained by double-track cross braiding. Composite grounding material.

Embodiment 2

[0068] The first composite graphite ribbon is composited with 13 glass fibers, the second composite graphite ribbon is composited with 12 glass fibers and one 600D Kevlar fiber, and the single strand of the second composite graphite has a linear tension of 15N. With 48 first composite graphite wires as the inner core of the composite graphite wire, 24 second composite graphite wires are used to weave the outer composite graphite wire braiding layer, and a graphite composite grounding material with a diameter of about 23.5 mm is obtained by double-track cross weaving.

Embodiment 3

[0070] The first composite graphite ribbon is composited with 11 glass fibers and 2 nickel fibers, the second composite graphite ribbon is composited with 12 glass fibers and 1 600D Kevlar fiber, and the single strand of the second composite graphite has a linear tension of 15N. Using 56 first composite graphite wires as the inner core of the composite graphite wire, weaving the outer composite graphite wire braiding layer with 24 second composite graphite wires, and adopting a double-track cross weaving method to obtain a graphite composite grounding material with a diameter of about 27mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com