Lightning arrester grounding rod

A grounding rod and lightning arrester technology, which is applied in the field of lightning arrester grounding rods, can solve the problems of surface oxidation of grounding rods, the failure of lightning arresters to protect electrical equipment, and high maintenance costs, and achieve the effect of low ground resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

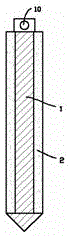

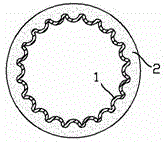

[0013] exist figure 1 In the first embodiment shown, the lightning arrester grounding rod includes a mandrel 1 made of metal with a high melting point; the upper end of the mandrel 1 has a terminal 10, and the lower end is tapered; the side wall of the mandrel 1 is wrapped with a The metal wall 2 is made of a metal with a low melting point.

[0014] For the grounding rod of the above lightning arrester, the metal with a high melting point is made of copper, iron or stainless steel with a melting point above 1500°C; the metal with a low melting point is made of aluminum with a melting point of about 660°C; the low melting point metal can also be made of a fuse However, when the fuse material is used, every time the lightning current flows, it will melt and solidify once, so that the metal wall will be consumed faster and the service life is not as good as aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com