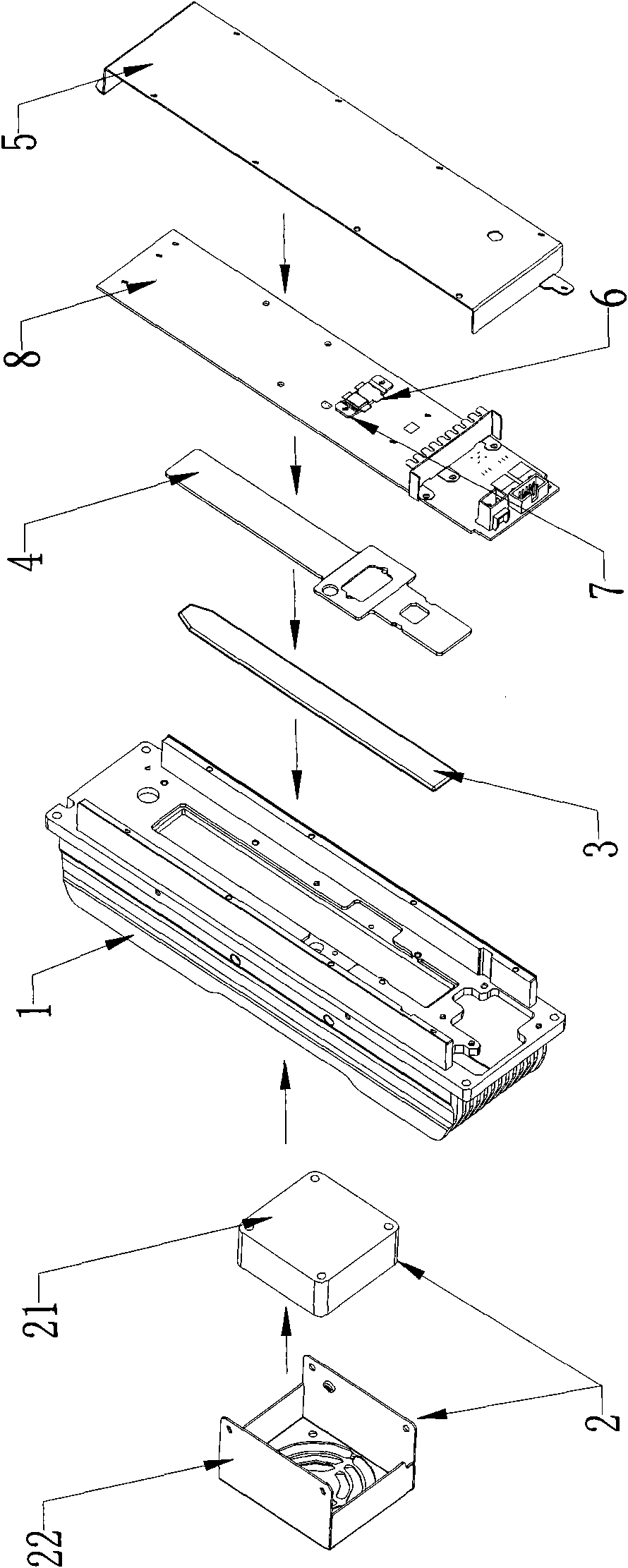

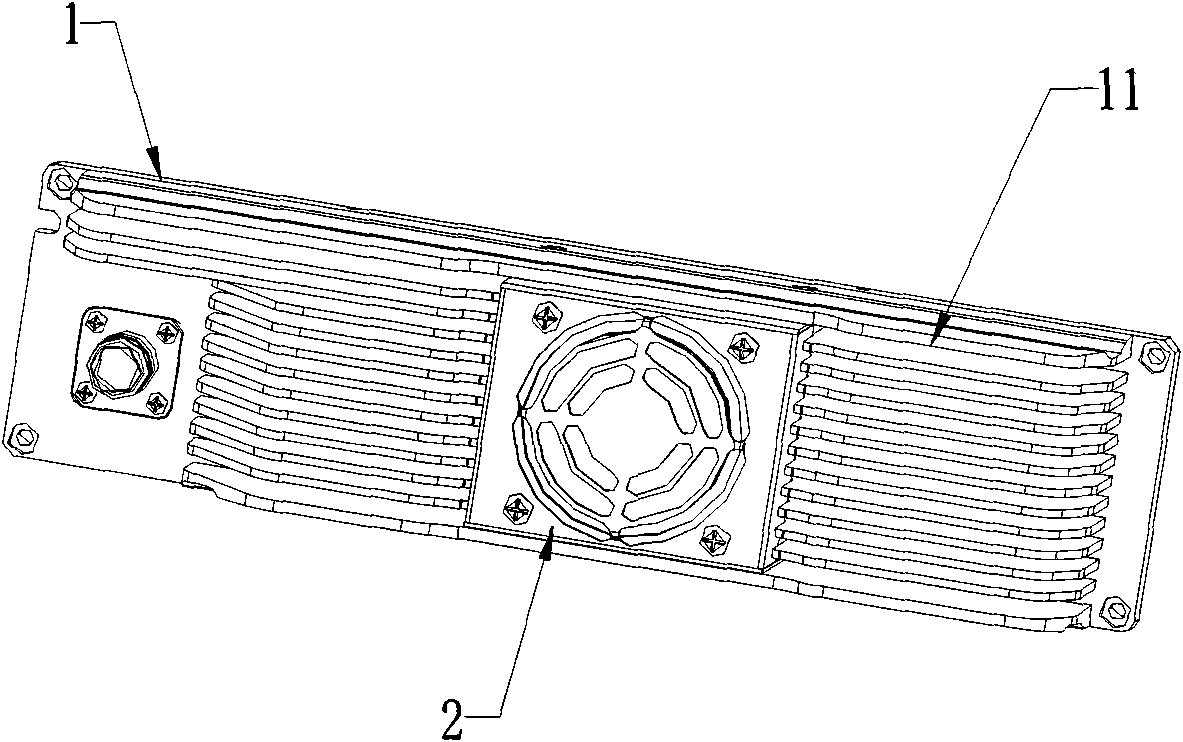

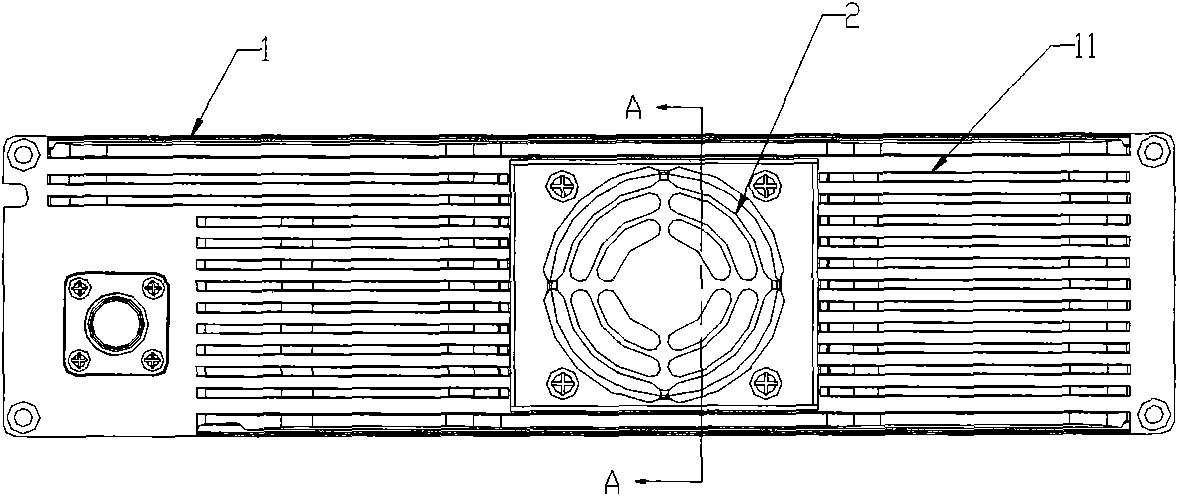

Radio frequency high-power heat pipe radiator

A heat pipe radiator, high-power technology, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of high cost, large radiator, etc., to improve heat dissipation performance and solve the effect of radio frequency grounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] Heat pipe technology uses the principle of phase change of working fluid to improve heat dissipation efficiency. It has been widely used in various industries and can be used in combination with natural heat dissipation cooling methods. The heat pipe is used for heat dissipation, and the heat dissipation efficiency is high, the radiator is small in size, and the cost is reasonable. However, heat pipe radiators are now mainly used in the PC industry, consumer electronics industry, medical equipment and public mobile communication industries. In the design and application of high-power heat dissipation in these industries, there is generally no requirement for radio frequency grounding, and the close contact between the heat source and the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com