Apparatus for automatically replenishing and maintaining specific concentration of coolant

A self-replenishing, concentration-specific technology used in maintenance and safety accessories, metalworking machinery parts, metalworking equipment, etc., to solve problems such as waste, increased corrosion and bacterial contamination, liquid spillage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

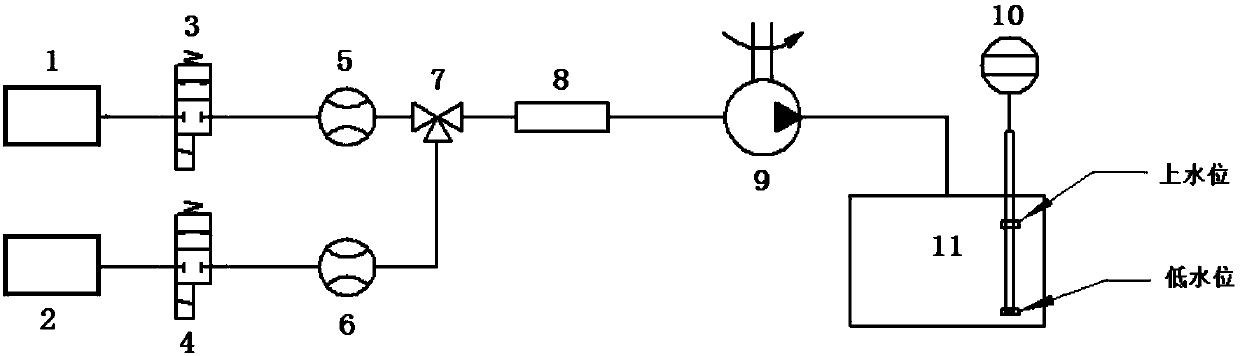

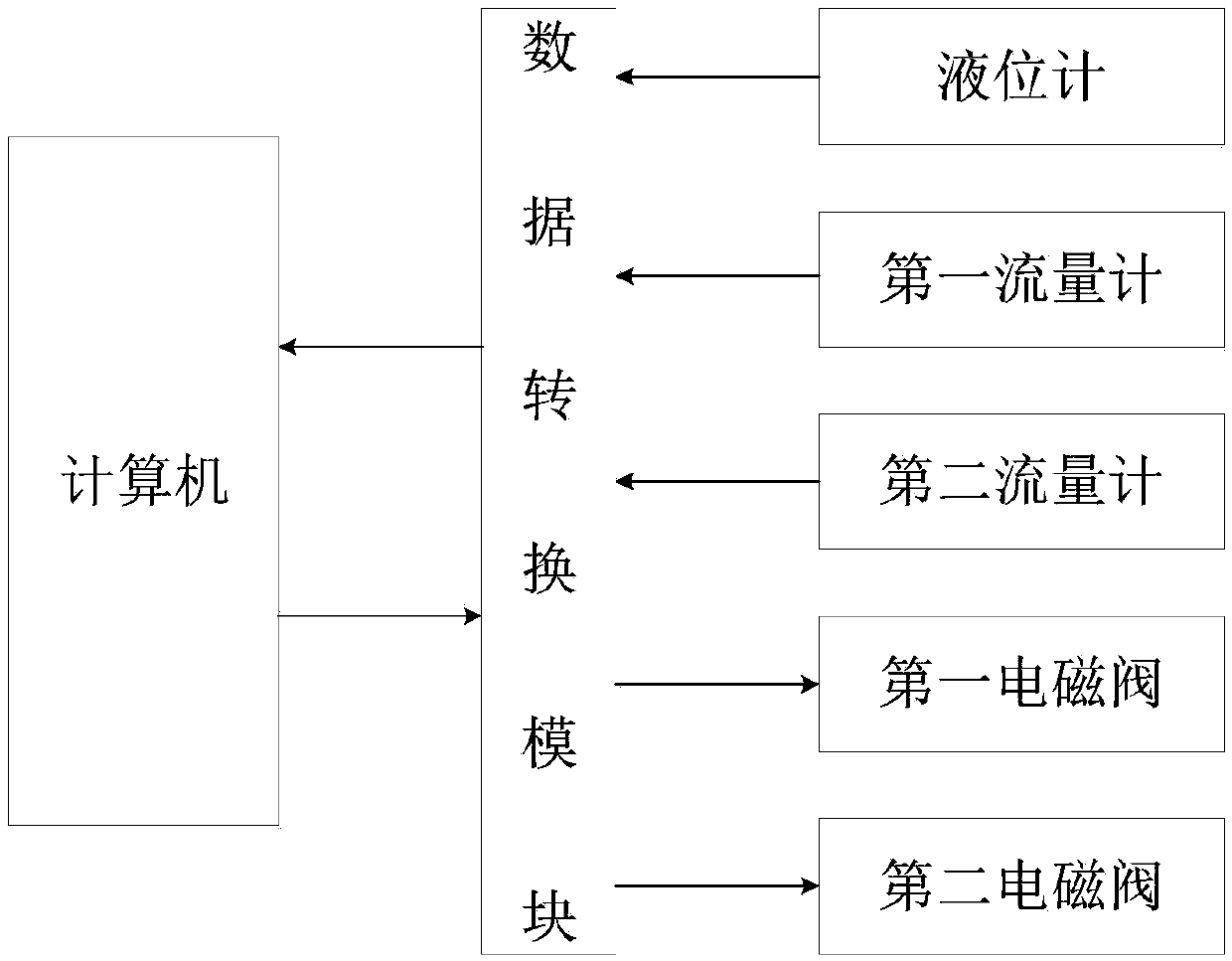

[0016] Embodiment 1: The cooling liquid of the present invention automatically replenishes and maintains a specific concentration system such as figure 1 shown. The whole system consists of water inlet 1, original liquid coolant filling port 2, first solenoid valve 3, second solenoid valve 4, first flow meter 5, first flow meter 6, ejector 7, pipeline mixer 8, water pump 9 And liquid level gauge 10 etc. composition. Wherein the water inlet 1 is connected with the inlet of the first solenoid valve 3, the outlet of the first solenoid valve 3 is connected with the inlet of the first flowmeter 5, and the outlet of the first flowmeter 5 is connected with the inlet of one end of the ejector 7; The inlet of the second electromagnetic valve 4 is connected, the outlet of the second electromagnetic valve 4 communicates with the inlet of the second flowmeter 6, the outlet of the second flowmeter 6 is connected with the inlet of the other end of the ejector 7; the outlet of the ejector 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com