Circulating cooling water quality monitoring system and equipment

A technology of circulating cooling water and monitoring system, applied in the direction of analyzing materials, instruments, etc., can solve the problems of incomplete response, few control parameters, and limitations, and achieve the effects of reducing sewage discharge, high cost, and saving supplementary water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

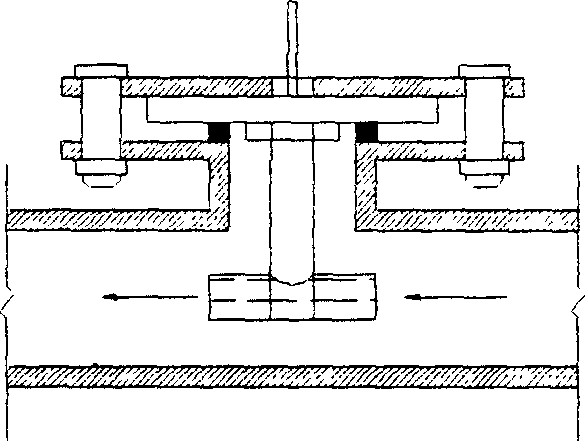

[0054] The electrode probe is directly installed on the process pipeline, or connected by flange. Specifications: Stainless steel casing: φ25×100mm

[0055] PTFE sheath: φ25×25mm

[0056] Ceramic core: φ20×120mm

[0057] Examples of measuring sensitive components:

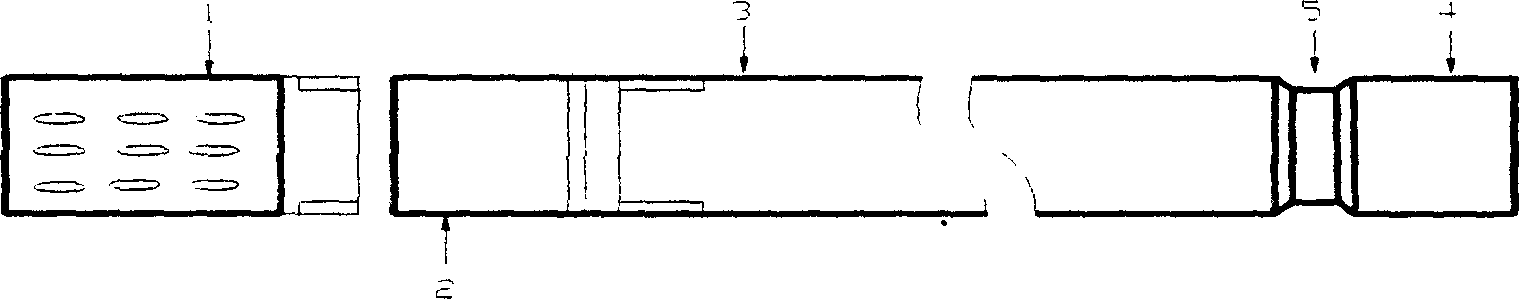

[0058] Measurement parameters

response range

sensitive material

Dimensions (mm)

Remark

central reference electrode

Ag / AgCl

φ2×120

filamentous

pH

0~14.0

φ3×120

Non-fluid type

Solution conductivity (μS /

cm)

0~20

platinum black

φ2×120

filamentous

Hardness (mg / L)

0~500

Sensitive to calcium and magnesium ions

film

φ3×120

filamentous

Cl - Concentration (mg / L)

Optional for stainless steel equipment

0~500

AgCl / Ag2S solid state

film

φ3×120

filamentous

Select 0~ for carbon steel equipment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com