Electroplating equipment capable of automatically supplementing anode material

A technology for anode materials and electroplating equipment, applied in the electrolysis process, electrolysis components, cells, etc., can solve problems such as difficulties and waste of materials, and achieve the effects of improving concentration, avoiding waste, and improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

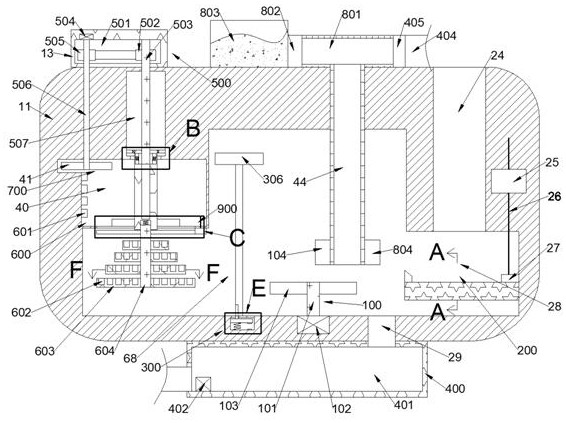

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0033] Such as Figure 1-8 As shown, a kind of electroplating equipment capable of automatically replenishing anode materials includes a box body 11, an electrolytic tank 68 is arranged inside the box body 11, and an electrolytic tank for electrolysis in the electrolytic tank 68 is provided on the bottom wall of the electrolytic tank 68. A mixing mechanism 100 for mixing the liquid, so that the mixing mechanism 100 is used for stirring and mixing the electrolyte in the electrolytic cell 68 to prevent precipitation of the electrolyte;

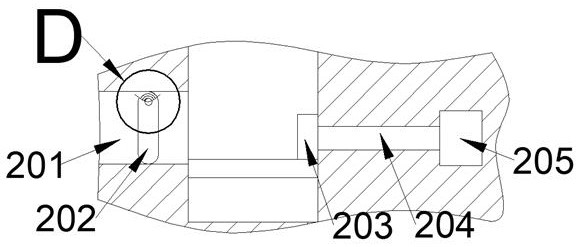

[0034] The end walls on both sides of the electrolytic cell 68 are symmetrically provided with cavities 28 with respect to the two sides of the stirring shaft 101. A cathode plate 27 is fixedly installed on the end walls of the cavity 28. Between the cathode plate 27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com