Preparation method of ZnO nano-structure with petal effect

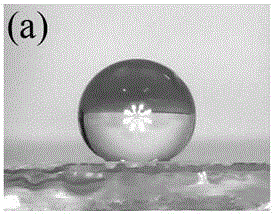

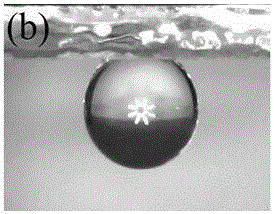

A technology of petal effect and nanostructure, applied in the field of nanomaterials, can solve problems such as strong adhesion, complicated preparation process, and indistinct surface petal effect, and achieve strong adhesion and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method of a zinc oxide nanostructure with petal effect, comprising the following steps:

[0023] 1. Preparation of zinc salt sol:

[0024] Add zinc acetate to ethylene glycol methyl ether to obtain a zinc acetate solution, add ethanolamine stabilizer to the zinc acetate solution, heat and stir in a water bath at 60°C for 2 hours, and age for 24 hours to obtain a colorless transparent sol.

[0025] 2. Preparation of Zinc Oxide Seed Crystal:

[0026] A glass slide was selected as the film growth substrate, ultrasonically cleaned in acetone and deionized water for 10 min, dried at 60°C, and set aside.

[0027] The spin coating method is used for coating. The sol is dripped onto the substrate at a low speed of 1500rpm, and the sol is uniformed at a high speed of 3000rpm. The time for 30s is to form a wet film, and then the wet film is pretreated. The temperature and time are respectively 150°C and 10min; repeat the above coating and pretreatment steps once o...

Embodiment 1

[0031] 1. Dissolve 8.78g of zinc acetate in 80ml of ethylene glycol methyl ether to obtain a zinc acetate solution with a concentration of 0.5mol / L, add 2.4mL of ethanolamine to the solution as a stabilizer, and heat and stir the solution in a water bath at 60°C for 2 hours. After aging for 24 hours, a colorless transparent sol was obtained.

[0032] 2. Use the spin coating method for coating, drop the transparent sol prepared in step 1 on the substrate at a low speed of 1500rpm, and uniform the glue at a high speed of 3000rpm. The time for uniform glue is 30s to form a wet film. For treatment, the temperature and time are 150°C and 10min, respectively; repeat the above coating and pretreatment steps once on the coated and pretreated substrate; finally put it into a high-temperature tube furnace for annealing treatment, the temperature is 500°C, and keep warm for 60min After natural cooling, zinc oxide seed crystals are obtained.

[0033] 3. Dissolve 0.238g of zinc nitrate he...

Embodiment 2

[0040] The preparation method of the zinc oxide seed crystal is as described in Example 1.

[0041] Dissolve 0.238g of zinc nitrate hexahydrate and 0.112g of hexamethylenetetramine in 38.8mL of deionized water, and add 1.2mL of ammonia water to adjust the pH value of the solution to 10.90, place the mixed solution in an autoclave, and then prepare The substrate with the zinc oxide seed layer is immersed in the mixed solution face down, hydrothermally reacted at 95°C for 2 hours, cooled naturally, washed with deionized water, dried at 80°C, and then placed in the atmosphere for a period of time. ZnO nanostructures with petal effect were obtained.

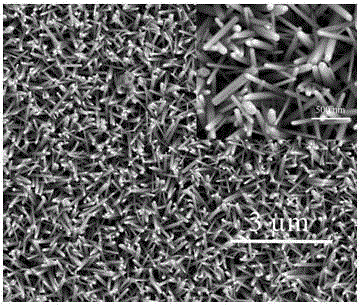

[0042] The zinc oxide nanostructure prepared in Example 2 consists of a large number of pointed zinc oxide nanorods of different thicknesses growing along the direction perpendicular to the surface of the substrate. The gaps between the nanorods are small and the distribution is relatively dense. The structure also has petals effect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com