Thermoplastic starch based on coordination effect as well as preparation method and application of thermoplastic starch

A thermoplastic starch and effect technology, applied in the field of thermoplastic starch and its preparation, can solve problems such as few detailed research reports on coordination, and achieve the effects of high coordination reaction efficiency, reducing free volume and improving hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

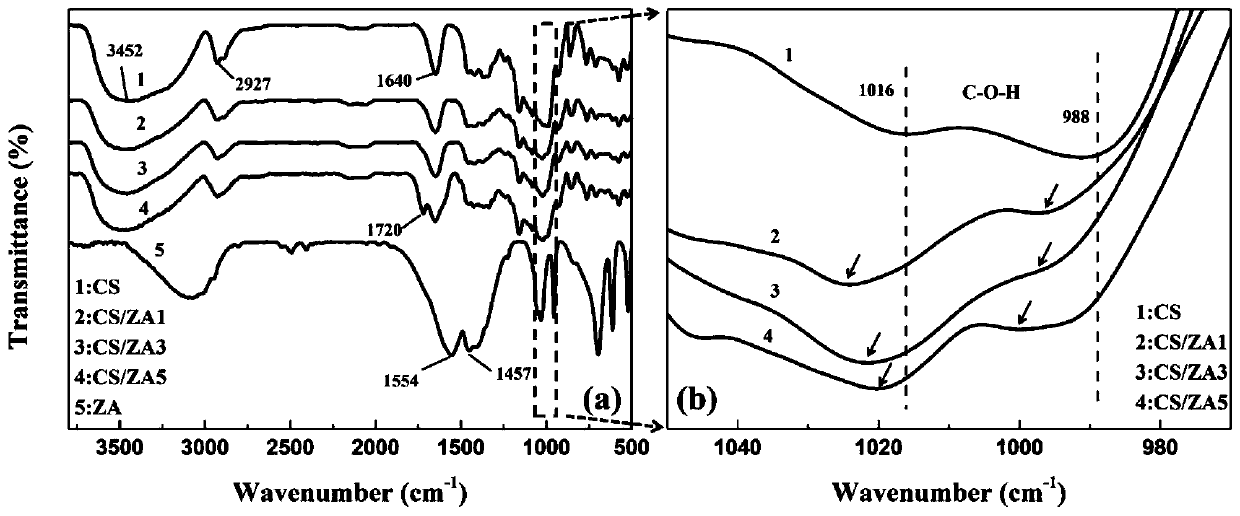

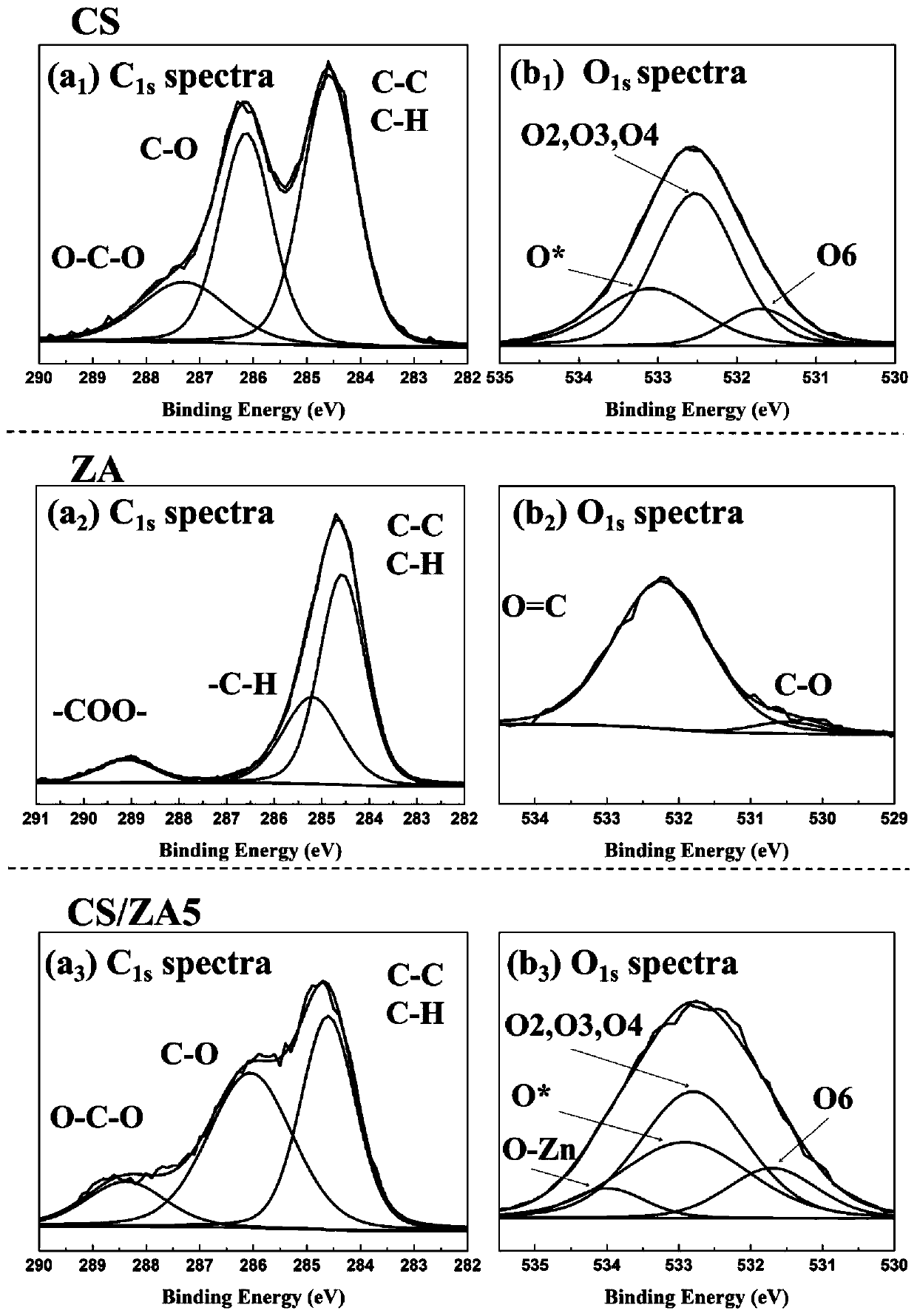

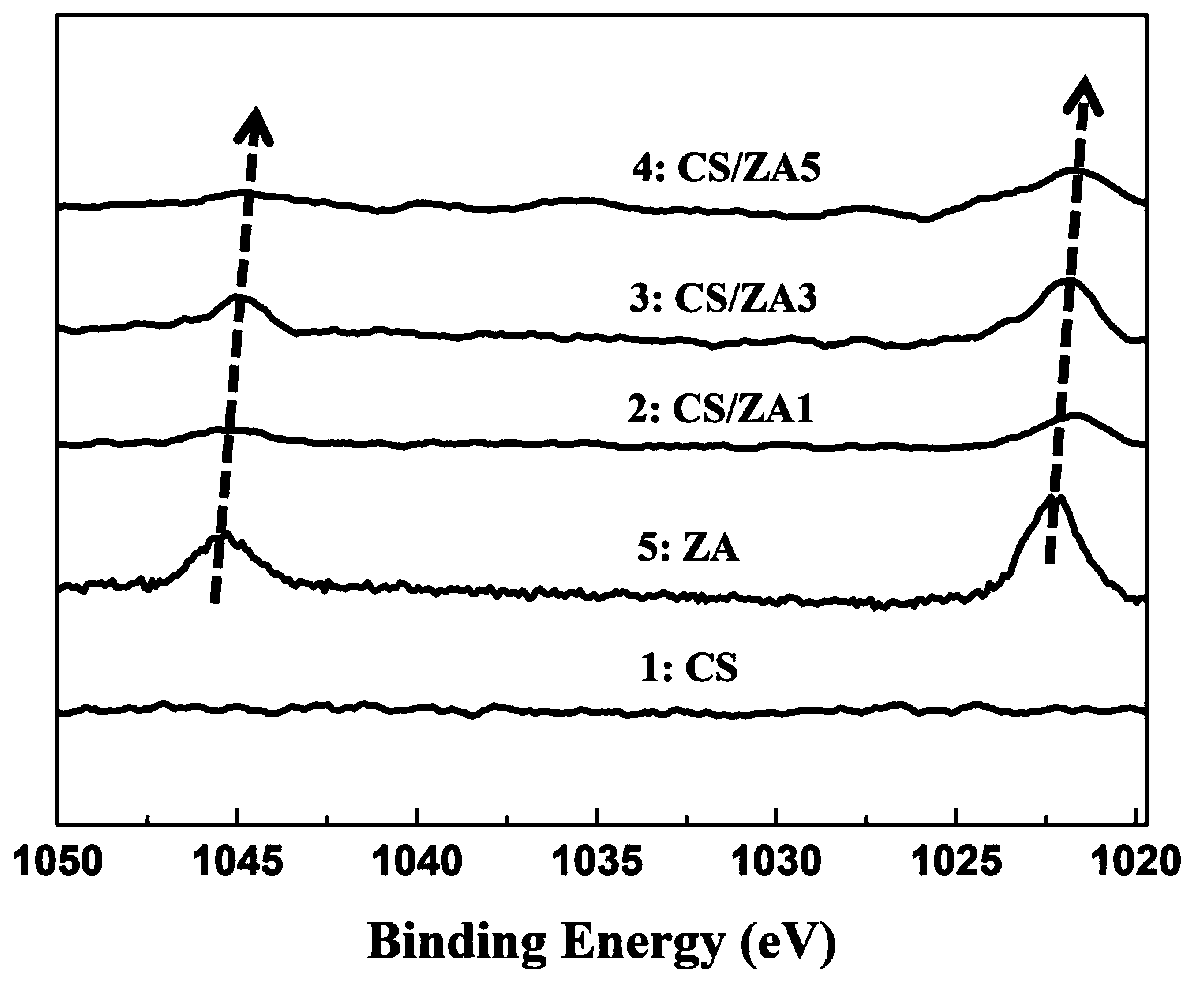

Embodiment 1

[0041]Dry the starch at 110°C for 4 hours, then pre-mix it with glycerin at a mass ratio of 7:3; then add anhydrous zinc acetate (ZA) accounting for 1% of the starch mass, and further mix to obtain a mixture, and then pass the mixture through a twin-screw extruder The thermoplastic starch based on the coordination effect (referred to as TPS-ZA1) is obtained by reactive extrusion and pelletizing. Put TPS-ZA1 in a Soxhlet extractor, use absolute ethanol as solvent, and purify at 95°C for 48 hours to obtain a purified thermoplastic starch based on coordination effect (referred to as CS / ZA1).

Embodiment 2

[0043] Dry the starch at 110°C for 4 hours, then pre-mix it with glycerin at a mass ratio of 7:3; then add anhydrous zinc acetate (ZA) accounting for 3% of the starch mass, and further mix to obtain a mixture, and then pass the mixture through a twin-screw extruder The thermoplastic starch based on the coordination effect (referred to as TPS-ZA3) is obtained by reactive extrusion and pelletizing. Put TPS-ZA3 in a Soxhlet extractor, use absolute ethanol as solvent, and purify at 95°C for 48 hours to obtain a purified thermoplastic starch based on coordination effect (referred to as CS / ZA3).

Embodiment 3

[0045] Dry the starch at 110°C for 4 hours, then pre-mix it with glycerin at a mass ratio of 7:3; then add anhydrous zinc acetate (ZA) accounting for 5% of the starch mass, and further mix to obtain a mixture, and then pass the mixture through a twin-screw extruder The thermoplastic starch based on the coordination effect (referred to as TPS-ZA5) is obtained by reactive extrusion and pelletizing. Put TPS-ZA5 in a Soxhlet extractor, use absolute ethanol as solvent, and purify at 95°C for 48 hours to obtain a purified thermoplastic starch based on coordination effect (referred to as CS / ZA5).

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com