High-heat-conductivity and high-temperature stability electronic packaging composite material and preparation method thereof

A technology of high temperature stability and electronic packaging, applied in the field of packaging materials, to achieve the effects of excellent high temperature stability, low moisture absorption performance, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

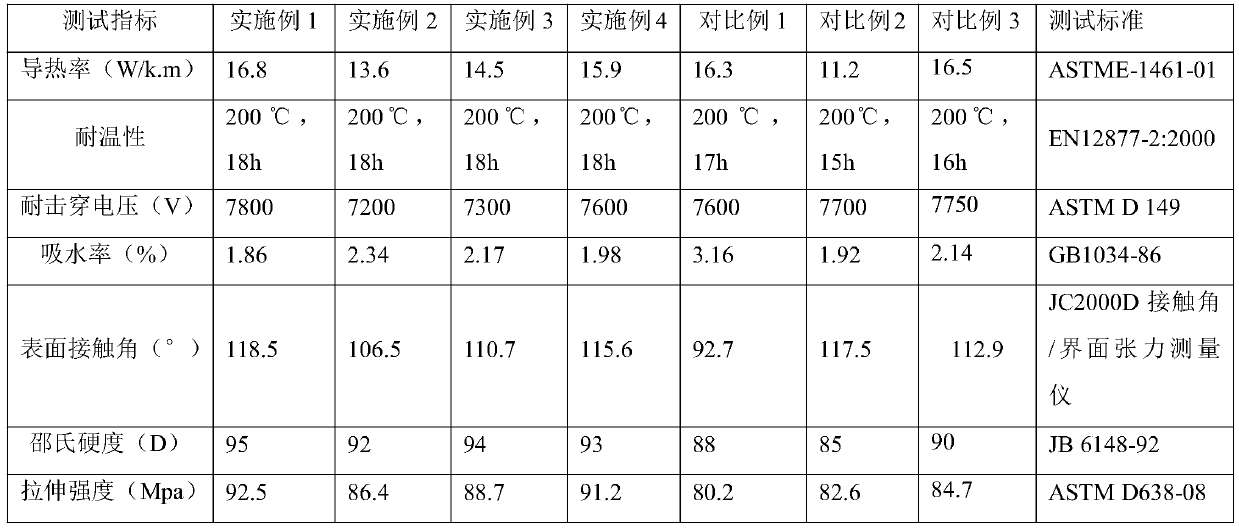

Examples

Embodiment 1

[0021] A high-temperature stable electronic packaging composite material with high thermal conductivity, prepared from the following raw materials in parts by weight: 40 parts of water-based polyurethane modified by 3-aminopropyltriethoxysilane, 23 parts of polyimide siloxane 15 parts of ethylene-vinyl acetate copolymer, 8 parts of carbon nanotubes, 7 parts of graphene oxide, 3.5 parts of ceramic microbeads, 9 parts of molybdenum disulfide, 4.5 parts of boron nitride, 3.5 parts of silane coupling agent, tetrahydro 6 parts of phthalic anhydride, 10 parts of diphenylmethane diisocyanate, 5.5 parts of diaminodiphenylmethane, 3.5 parts of 2-ethyl-4-methylimidazole, 4.5 parts of ethylene glycol dimethacrylate, poly 3 parts of propylene glycol diglycidyl ether, 2.5 parts of dispersant, 2 parts of defoamer, 1.5 parts of leveling agent, and 15 parts of solvent.

[0022] The silane coupling agent is γ-glycidyl etheroxypropyltrimethoxysilane.

[0023] The dispersant is sodium carboxyme...

Embodiment 2

[0032] A high-temperature stable electronic packaging composite material with high thermal conductivity, prepared from the following raw materials in parts by weight: 30 parts of water-based polyurethane modified by 3-aminopropyltriethoxysilane, 15 parts of polyimide siloxane 10 parts of ethylene-vinyl acetate copolymer, 5 parts of carbon nanotubes, 4 parts of graphene oxide, 2 parts of ceramic microbeads, 6 parts of molybdenum disulfide, 3 parts of boron nitride, 2 parts of silane coupling agent, tetrahydrogen 4 parts of phthalic anhydride, 7 parts of diphenylmethane diisocyanate, 4 parts of diaminodiphenylmethane, 2-5 parts of 2-ethyl-4-methylimidazole, 3 parts of ethylene glycol dimethacrylate , 1 part of polypropylene glycol diglycidyl ether, 1 part of dispersant, 1 part of defoamer, 0.5 part of leveling agent, and 10 parts of solvent.

[0033] The silane coupling agent is γ-methacryloxypropyltrimethoxysilane.

[0034] Described dispersant is polyethylene glycol 400.

[...

Embodiment 3

[0043] A high-temperature stable electronic packaging composite material with high thermal conductivity, prepared from the following raw materials in parts by weight: 35 parts of water-based polyurethane modified by 3-aminopropyltriethoxysilane, 20 parts of polyimide siloxane 12 parts of ethylene-vinyl acetate copolymer, 6 parts of carbon nanotubes, 5 parts of graphene oxide, 3 parts of ceramic microbeads, 8 parts of molybdenum disulfide, 4 parts of boron nitride, 3 parts of silane coupling agent, tetrahydrogen 5 parts of phthalic anhydride, 8 parts of diphenylmethane diisocyanate, 5 parts of diaminodiphenylmethane, 3 parts of 2-ethyl-4-methylimidazole, 4 parts of ethylene glycol dimethacrylate, poly 3 parts of propylene glycol diglycidyl ether, 2 parts of dispersant, 1.5 parts of defoamer, 1 part of leveling agent, 12 parts of solvent.

[0044] The silane coupling agent is γ-glycidyl etheroxypropyltrimethoxysilane.

[0045] The dispersant is polyvinylpyrrolidone.

[0046] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com