Vehicle paint film based on nanometer composite material, and preparation method thereof

A nano-composite material and car paint technology, applied in the field of car paint film, can solve the problems of poor impact resistance of car paint, volatile harmful substances, easy agglomeration of nano-powders, etc., and achieve excellent salt spray resistance and surface contact angle. The effect of improving and increasing the surface contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

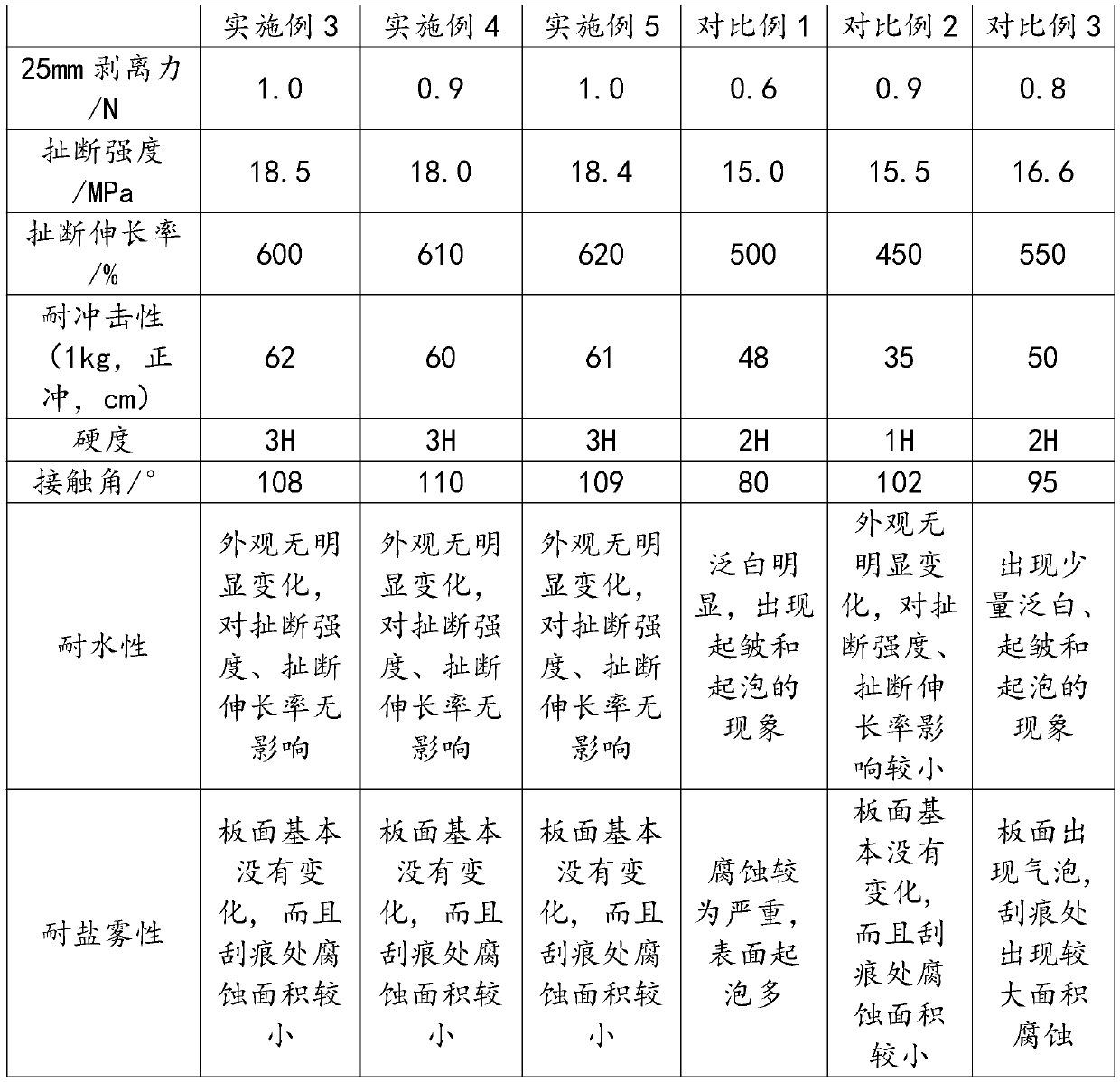

Examples

preparation example Construction

[0045] The preparation method of the car paint film based on the nanocomposite material comprises the following steps:

[0046] Step S1, put the nanocomposite material and carnauba wax into a beaker, add 1 / 3 of deionized water, 1 / 3 of defoamer, wetting and dispersing agent, stir at 1000r / min for 15-30min, and then shake at high speed Shake the machine for 30-50 minutes to obtain the premix;

[0047] Step S2, under the stirring condition of 1000r / min, add the premix prepared in step S1 into the modified modified acrylic emulsion, then add the remaining deionized water and defoamer, stir for 40-50min, add thickening agent, adjust the liquid viscosity to be 20-25S, and obtain the car paint film coating;

[0048] Step S3, pre-cleaning and drying the surface of the car paint. Compared with the traditional cleaning pre-treatment, attention should be paid to strengthening the pre-cleaning wiping process and adjusting the cleaning spray;

[0049] Specifically, strengthen the pre-cle...

Embodiment 1

[0054] Preparation of modified acrylic emulsion:

[0055] (1) Add 19.9 g of hydroxyethyl methylcellulose, 16.74 g of perfluorobutyl ethyl methacrylate, 136.5 g of n-butyl acrylate, 137.3 g of methyl methacrylate, and Acrylic acid 5.2g, methacrylate ethylene urea ethoxylate 5g, fully stirred for 30min to obtain the first pre-emulsion;

[0056] (2) Add 5.5 g of hydroxyethyl methylcellulose, 8 g of perfluorobutyl ethyl methacrylate, 40 g of n-butyl acrylate, 135 g of methyl methacrylate, and 2 g of methacrylic acid in 45 g of deionized water. 1 g of ethylene urea ethoxy methacrylate, fully stirred for 0.5 h to obtain the second pre-emulsion;

[0057] (3) Add 280g deionized water and 2.2g maleic acid ester type emulsifier in the flask that reflux condenser, thermometer and stirring device are housed, temperature is raised to 85 ℃, add 10% under the constant temperature condition of 85 ℃ Stir the first pre-emulsion for 10 minutes, then add 0.6 g of sodium metabisulfite, and after...

Embodiment 2

[0059] Preparation of nanocomposites:

[0060] (1) Weigh 6g of microcrystalline cellulose and add it to 60mL of sulfuric acid solution with a mass fraction of 68%, stir at room temperature for 20min at 200r / min, heat, and keep stirring for 2h after the temperature rises to 45°C;

[0061] (2) Take out the precipitate and add 60mL of deionized water to the precipitate, centrifuge at 4000r / min for 5min, and repeat the centrifugation until the supernatant becomes turbid;

[0062] (3) Put the precipitate and nano-silicon carbide into the dialysis bag according to the mass ratio of 2:1 and dialyze until the pH of the system is 7, and finally move the dialyzed product into a high-pressure homogenizer for high-pressure homogenization treatment. The pressure is 80MPa, and the number of cycles is 5 times to obtain a nanocomposite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength at break | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com