High-fouling-resistant inorganic silicate coating prepared from fluorine-containing polymer and preparation method and application of coating

An inorganic silicate and antifouling technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problem that phase separation materials cannot effectively function, performance cannot be effectively improved, and very It is difficult to add water-based coatings and other problems to achieve excellent hydrophobic properties, excellent weather resistance, and the effect of improving the contact angle of the coating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

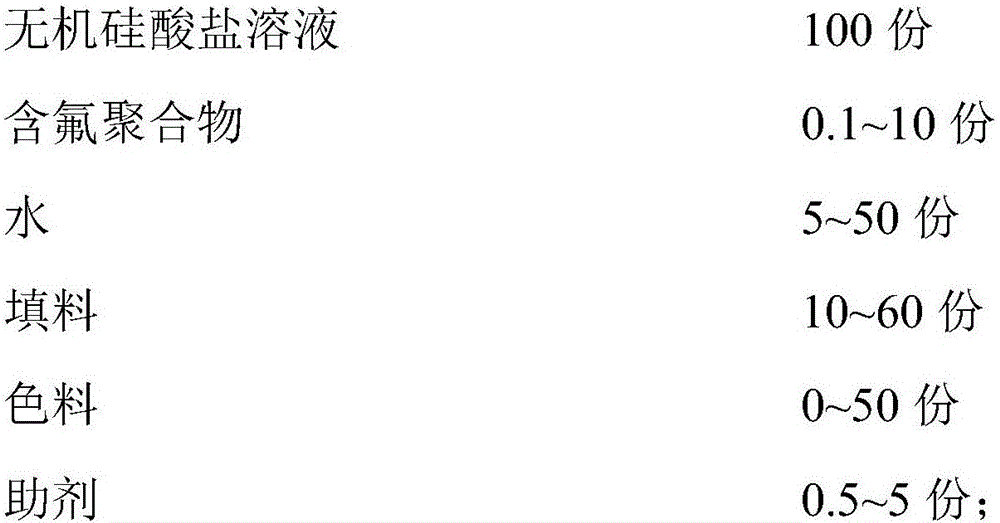

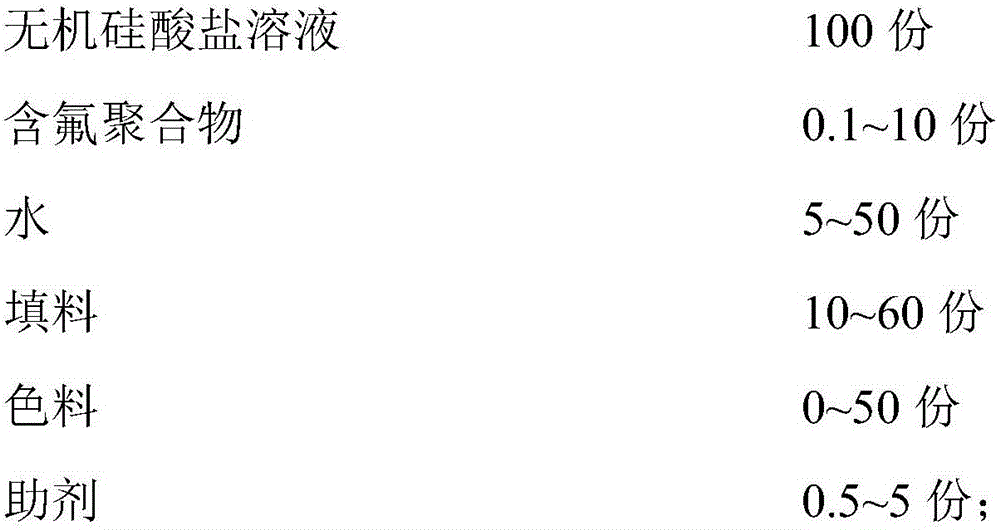

Method used

Image

Examples

Embodiment 1

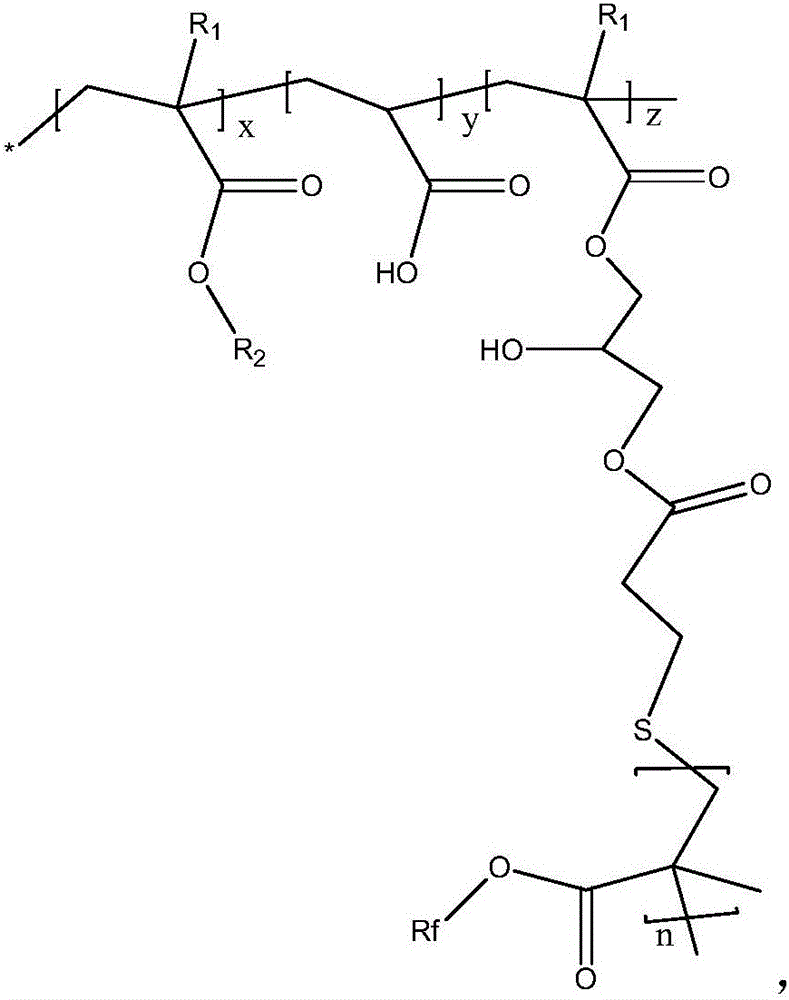

[0032] (1) Preparation of fluorine-containing side chain: 0.1kg azobisisobutyronitrile is joined in 50kg methyl ethyl ketone solvent, add reaction monomer 50kg hexafluorobutyl methacrylate and 50kg trifluoroethyl methacrylate, in React at 40° C. for 13 hours, then add 1 kg of mercaptoacetic acid as a chain transfer agent to prepare fluorine-containing side chains.

[0033] (2) Preparation of fluoropolymer: 1kg of azobisisobutyronitrile is added to 50kg of methyl ethyl ketone solvent, and then 10kg of reaction monomers, 10kg of acrylic acid, 25kg of (meth)acrylate, and 35kg of glycidyl methacrylate are added , reacted at 80°C for 8 hours. Then add the fluorine-containing side chain prepared in (1) into the reaction vessel, add 0.01 kg of catalyst hydrochloric acid, react at 30° C. for 5 hours, and then remove the solvent by rotary evaporation to obtain the fluorine-containing acrylate polymer. That is, fluoropolymers.

[0034] (3) Add 0.1kg of fluoropolymer to 10kg of water, ...

Embodiment 2

[0037] (1) Preparation of fluorine-containing side chains: Add 5kg of initiator azobisisoheptanonitrile to 50kg of solvent ethyl acetate, add 100kg of reaction monomer dodecafluoroheptyl methacrylate, and react at 50°C for 15 hours , Then add chain transfer agent 0.8kg mercaptoacetic acid, make fluorine-containing side chain.

[0038](2) Preparation of fluoropolymer: 0.5kg of initiator azobisisoheptanonitrile is added to 50kg of solvent ethyl acetate, then 15kg of reaction monomers acrylic acid, 10kg (meth)methyl acrylate, 5kg (Meth) isobutyl acrylate, 5 kg (meth) isooctyl acrylate, and 10 kg glycidyl methacrylate were reacted at 80° C. for 6 hours. Then add the fluorine-containing side chain prepared in (1) into the reaction vessel, add 0.2kg of catalyst sodium hydroxide, react at 90°C for 3 hours, and then remove the solvent by rotary evaporation to obtain the fluorine-containing acrylate polymer substances, namely fluoropolymers.

[0039] (3) Add 2kg of fluoropolymer to 5...

Embodiment 3

[0042] (1) Preparation of fluorine-containing side chains: 2kg initiator benzoyl peroxide, 2kg initiator lauroyl peroxide are added to 50kg solvent toluene, 30kg hexafluorobutyl methacrylate, 30kg methyl Dodecafluoroheptyl acrylate was reacted at 100° C. for 7 hours, and then 0.5 kg of chain transfer agent mercaptoacetic acid was added to prepare fluorine-containing side chains.

[0043] (2) Preparation of fluoropolymers: 0.6kg of initiator dicyclohexyl peroxydicarbonate is added to 50kg of solvent toluene, then 30kg of reaction monomers are added: acrylic acid, 35kg (meth)butyl acrylate, 20kg Glycidyl methacrylate was reacted at 40°C for 15 hours. Then add the fluorine-containing side chain prepared in (1) into the reaction vessel, add 0.4kg of catalyst 0.1mol / L hydrochloric acid, react at 100°C for 4 hours, and then remove the solvent by rotary evaporation to obtain fluorine-containing acrylic acid Ester polymers, ie fluoropolymers.

[0044] (3) Add 10kg of fluoropolymer t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com