Special modifying agent for water-permeable concrete and preparation method thereof

A technology of permeable concrete and modifier, applied in the field of concrete, can solve the problems of failing to achieve the strength and permeable performance of permeable concrete, failing to take into account the durability of permeable concrete, structural stability, decreased safety, etc. performance, improving strength, preventing moisture evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

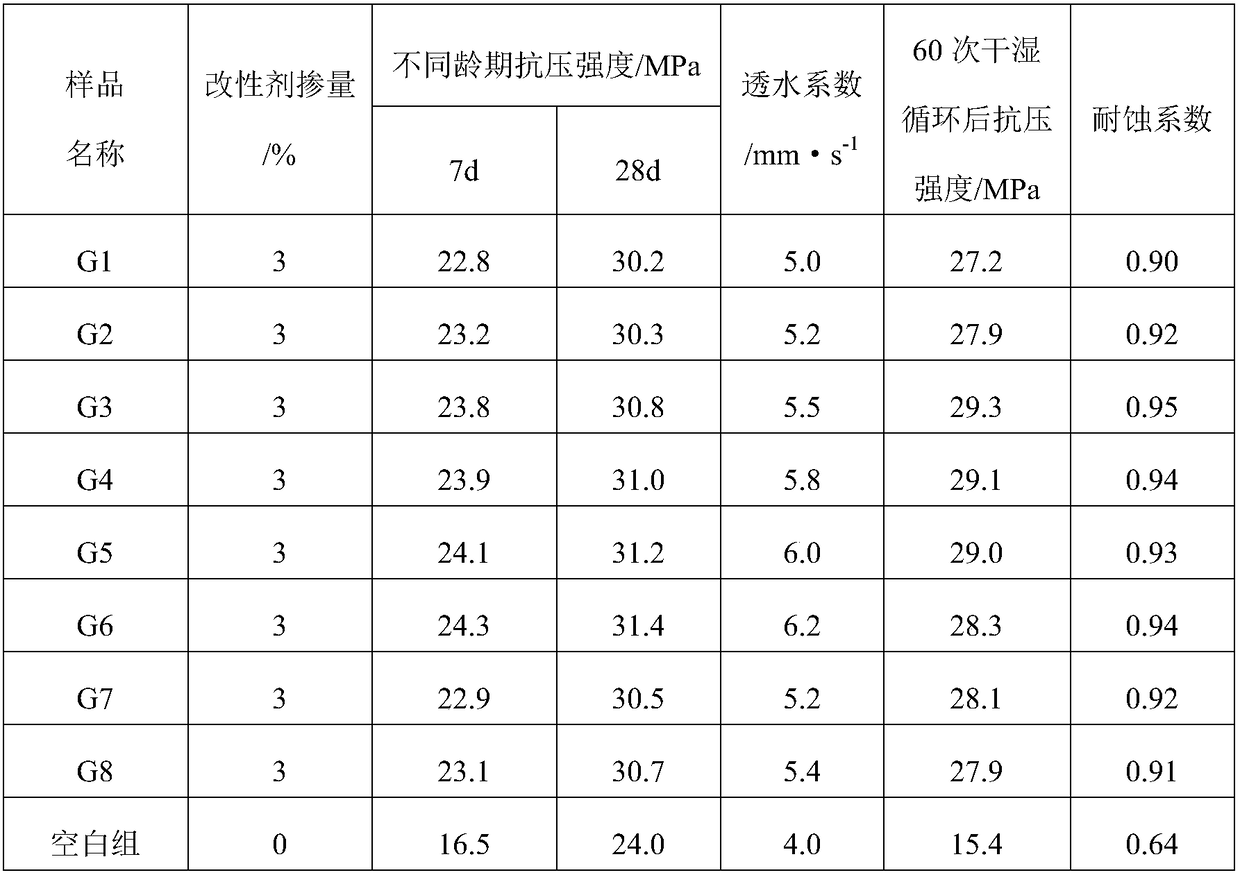

Examples

Embodiment 1

[0045] The special modifier for permeable concrete of the present embodiment comprises the following components by mass percentage:

[0046] Long carbon chain silane 10%, dispersant 58%, polysiloxane resin 7%, fluorocarbon resin emulsion 7%, deionized water 18%, of which long carbon chain silane is isobutyl triethoxysilane, dispersant to ethanol.

[0047] The preparation method of special modifier for permeable concrete is as follows:

[0048] a. At a temperature of 10-40°C, add dispersant (ethanol) and deionized water with 0.1 times the total mass of deionized water to the reaction kettle in sequence, and adjust the pH value after stirring for 10 minutes at a speed of 120r / min 2 to 3 to obtain solution A; add long carbon chain silane (isobutyltriethoxysilane) to solution A, stir at a rotation speed of 240r / min, and keep warm for 40 minutes to obtain a hydrophobic agent.

[0049] b. Add the rest of the water to the production equipment first, then add the hydrophobic agent a...

Embodiment 2

[0053] The special modifier for permeable concrete of the present embodiment comprises the following components by mass percentage:

[0054] Long carbon chain silane 11%, dispersant 60%, polysiloxane resin 5%, fluorocarbon resin emulsion 5%, deionized water 19%, of which long carbon chain silane is isooctyl triethoxysilane, dispersant is isopropanol.

[0055] The preparation method of special modifier for permeable concrete is as follows:

[0056] a. At a temperature of 10-40°C, add a dispersant (isopropanol) and deionized water with a total mass of 0.15 times the total mass of deionized water to the reaction kettle in sequence, and then adjust the pH value after stirring at a speed of 120r / min for 10min 2 to 3 to obtain A solution; add long carbon chain silane (isooctyltriethoxysilane) to A solution, stir at a rotation speed of 240r / min, and keep warm for 40 minutes to obtain a hydrophobic agent.

[0057] b. Add the rest of the water to the production equipment first, then ...

Embodiment 3

[0061] The special modifier for permeable concrete of the present embodiment comprises the following components by mass percentage:

[0062] Long carbon chain silane 12%, dispersant 54%, polysiloxane resin 10%, fluorocarbon resin emulsion 10%, deionized water 14%, of which long carbon chain silane is isobutyltriethoxysilane, dispersant for acetone.

[0063] The preparation method of special modifier for permeable concrete is as follows:

[0064] a. At a temperature of 10-40°C, add a dispersant (acetone) and deionized water with 0.2 times the total mass of deionized water to the reaction kettle in sequence, and stir for 8 minutes at a speed of 100r / min, then adjust the pH value to 2 ~3, to obtain solution A; add long carbon chain silane (isobutyltriethoxysilane) to the solution A, stir at a rotation speed of 200r / min, and keep warm for 30min to obtain a hydrophobic agent.

[0065] b. Add the rest of the water to the production equipment first, then add the hydrophobic agent a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com