Warm-keeping and moisture-absorbing composite polyester fiber with synergistic effect of skin-core components and preparation method thereof

A synergistic, composite polyester technology, applied in the direction of fiber chemical characteristics, conjugated synthetic polymer rayon, rayon manufacturing, etc., to achieve high-efficiency light-to-heat conversion, reduce frictional resistance, and good lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

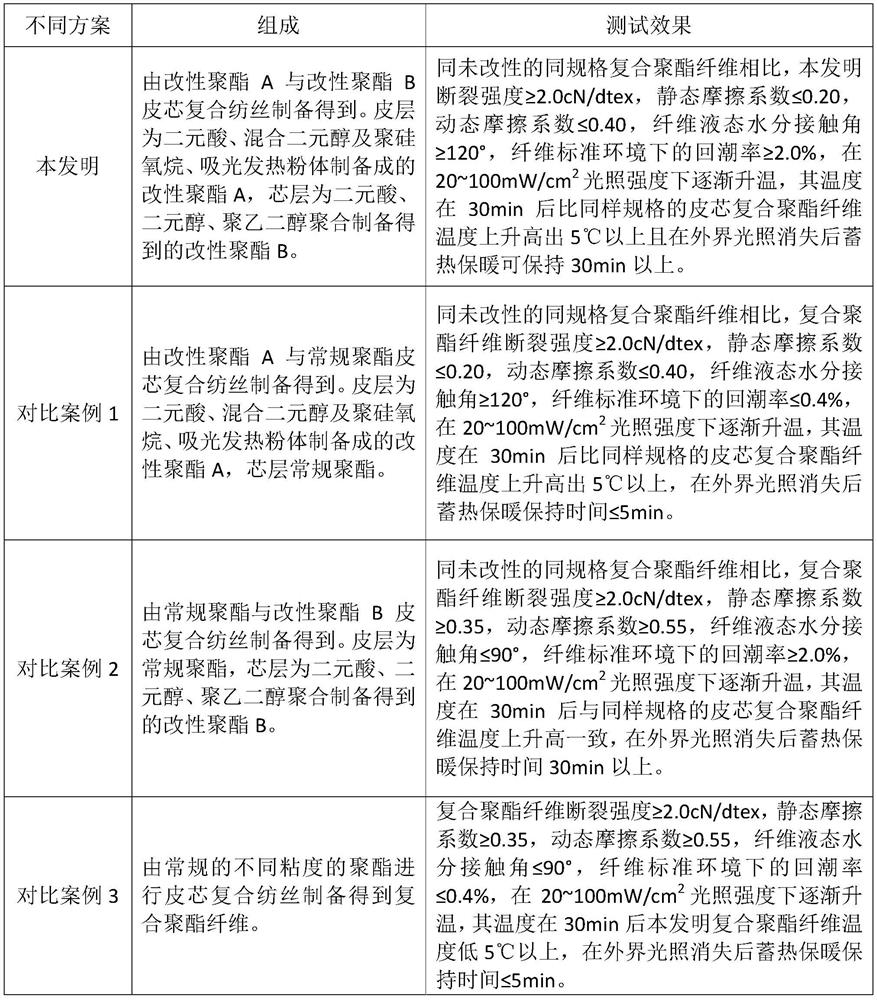

Examples

Embodiment 1

[0072] A method for preparing a warm-keeping and moisture-absorbing composite polyester fiber with synergistic effect of sheath and core components, comprising:

[0073] Step 1: Preparation of modified polyester A.

[0074] (1.1) Esterification reaction:

[0075] Esterification of dibasic acid, mixed diol and catalyst according to a certain molar ratio;

[0076] The dibasic acid is one of terephthalic acid, isophthalic acid, succinic acid, adipic acid, suberic acid and sebacic acid;

[0077] The mixed glycol is composed of a short-chain glycol and a long-chain glycol, the short-chain glycol is one of ethylene glycol, propylene glycol and butanediol, and the long-chain glycol is diethylene glycol , one of pentanediol and hexanediol;

[0078] The molar ratio of described dibasic acid and mixed dibasic alcohol is 1:1.1, and wherein the molar ratio of short-chain dibasic alcohol and long-chain dibasic alcohol is 4:6;

[0079] The catalyst is one of antimony ethylene glycol, an...

Embodiment 2

[0111] A method for preparing a warm-keeping and moisture-absorbing composite polyester fiber with synergistic effect of sheath and core components, comprising:

[0112] Step 1: Preparation of modified polyester A.

[0113] (1.1) Esterification reaction:

[0114] Esterification of dibasic acid, mixed diol and catalyst according to a certain molar ratio;

[0115] The dibasic acid is one of terephthalic acid, isophthalic acid, succinic acid, adipic acid, suberic acid and sebacic acid;

[0116] The mixed glycol is composed of a short-chain glycol and a long-chain glycol, the short-chain glycol is one of ethylene glycol, propylene glycol and butanediol, and the long-chain glycol is diethylene glycol , one of pentanediol and hexanediol;

[0117] The molar ratio of described dibasic acid and mixed dibasic alcohol is 1:1.5, and wherein the molar ratio of short chain dibasic alcohol and long chain dibasic alcohol is 6:4;

[0118] The catalyst is one of antimony ethylene glycol, an...

Embodiment 3

[0150] A method for preparing a warm-keeping and moisture-absorbing composite polyester fiber with synergistic effect of sheath and core components, comprising:

[0151] Step 1: Preparation of modified polyester A.

[0152] (1.1) Esterification reaction:

[0153] Esterification of dibasic acid, mixed diol and catalyst according to a certain molar ratio;

[0154] The dibasic acid is one of terephthalic acid, isophthalic acid, succinic acid, adipic acid, suberic acid and sebacic acid;

[0155] The mixed glycol is composed of a short-chain glycol and a long-chain glycol, the short-chain glycol is one of ethylene glycol, propylene glycol and butanediol, and the long-chain glycol is diethylene glycol , one of pentanediol and hexanediol;

[0156] The molar ratio of described dibasic acid and mixed dibasic alcohol is 1:2.0, and wherein the molar ratio of short-chain dibasic alcohol and long-chain dibasic alcohol is 8:2;

[0157] The catalyst is one of antimony ethylene glycol, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com