Hydrophobic flame-retardant epoxy resin and preparation method thereof

An epoxy resin, hydrophobic technology, applied in the field of functional polymer material preparation, can solve the problems of deterioration of mechanical properties, flicker and partial discharge, accelerated aging of epoxy resin, etc., to improve dispersibility and stability, good toughness and strength , the effect of improving the surface contact angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

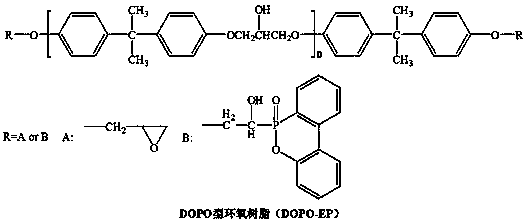

[0017] A preparation method of hydrophobic flame-retardant epoxy resin:

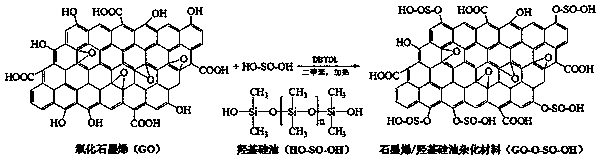

[0018] (1) Add 0.01–0.1 g of graphene oxide (GO) to 100–500 mL of xylene, and ultrasonicate at room temperature for 1–4 h to prepare a GO dispersion. Add 10-50 g of hydroxy silicone oil (HO-SO-OH) and 0.1-0.5 g of dibutyltin dilaurate (DBTDL) to the above dispersion, and continue ultrasonication at room temperature for 10-30 min. Heat up to 80-100 °C, mechanically stir and react for 6-12 h, the product is filtered, washed with xylene, and vacuum-dried at 60 °C for 24 h to prepare graphene / hydroxy silicone oil hybrid material;

[0019] Its reaction process is as follows:

[0020]

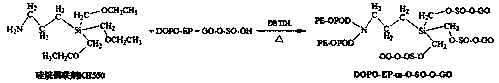

[0021] (2) Add 4-10 g of the hybrid material prepared in step (1), 80-100 g of DOPO epoxy resin, 1-2 g of silane coupling agent KH550 and 0.04-0.1 g of DBTDL into a single-necked Erlenmeyer flask in sequence , vacuum-stirred and reacted at 60-80 ℃ for 2-4 h to obtain uncured graphene / hydroxyl silicone oil / DOPO-type epoxy r...

Embodiment 1

[0032] (1) Add 0.01 g of graphene oxide (GO) into 100 mL of xylene, and ultrasonicate at room temperature for 1 h to prepare a GO dispersion. Add 10 g of hydroxy silicone oil and 0.1 g of dibutyltin dilaurate (DBTDL) to the above dispersion, and continue ultrasonication at room temperature for 10 min. The temperature was raised to 80 °C, mechanically stirred for 12 h, the product was filtered, washed with xylene, and vacuum-dried at 60 °C for 24 h to prepare a graphene / hydroxy silicone oil hybrid material;

[0033] (2) Add 4 g of the hybrid material prepared in step (1), 80 g of DOPO epoxy resin, 1 g of silane coupling agent KH550, and 0.04 g of DBTDL into a single-necked Erlenmeyer flask in turn, and stir under vacuum at 60 °C After reacting for 4 h, an uncured graphene / hydroxyl silicone oil / DOPO type epoxy resin composite was obtained;

[0034] (3) Add 80 g of the compound prepared in step (2), 40 g of phthalic anhydride and 0.3 g of N,N-dimethylbenzylamine into a polytetra...

Embodiment 2

[0036](1) 0.05 g graphene oxide (GO) was added to 300 mL xylene, and ultrasonicated at room temperature for 2 h to prepare a GO dispersion. Add 30 g of hydroxy silicone oil and 0.3 g of dibutyltin dilaurate (DBTDL) to the above dispersion, and continue ultrasonication at room temperature for 20 min. The temperature was raised to 90 °C, mechanically stirred for 9 h, the product was filtered, washed with xylene, and vacuum-dried at 60 °C for 24 h to prepare a graphene / hydroxy silicone oil hybrid material;

[0037] (2) Add 7 g of the hybrid material prepared in step (1), 90 g of DOPO-type epoxy resin, 1.5 g of silane coupling agent KH550 and 0.07 g of DBTDL into a single-necked Erlenmeyer flask, and stir under vacuum at 70 °C After reacting for 3 h, an uncured graphene / hydroxyl silicone oil / DOPO type epoxy resin composite was obtained;

[0038] (3) Add 90 g of the compound prepared in step (2), 50 g of methyltetrahydrophthalic anhydride and 0.4 g of N-benzylpyrazinium hexafluoro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com