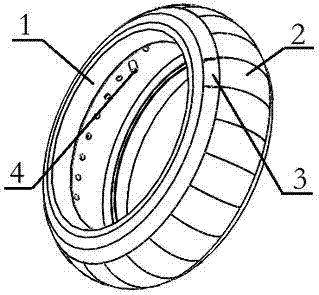

ZGM type repairable metal ceramic composite grinding roller and manufacturing method

A metal-ceramic composite and ceramic composite technology, applied in grain processing, etc., can solve problems such as high service life and cost, shedding of wear-resistant parts, high cost, etc., to improve stability and service life, improve impact resistance, and simple repair Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

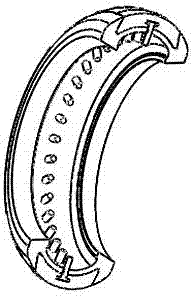

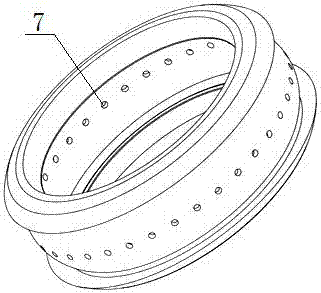

Method used

Image

Examples

Embodiment 1

[0045] A method for manufacturing a ZGM type repairable metal-ceramic composite grinding roller, comprising the steps of:

[0046] (1) Mix the pretreated and dried ceramic particles, alloy powder and binder in proportion, prepare a specific shape through a special mold, dry and shape it, and then prepare a preform by vacuum sintering;

[0047] (2) Take out the prefabricated body, put it in an oven at 200°C for preheating, then fix it in the cavity of the casting sand mold, and finally prepare the block ceramic composite grinding roller skin by casting the alloy melt;

[0048] (3) Through heat treatment, the hardness of the single ceramic composite grinding roller skin reaches 59HRC, and then the ceramic composite grinding roller skin is machined to prepare the required size and shape;

[0049] (4) Casting the matrix and blocks designed on the drawings, and machining them to meet the matching requirements;

[0050] (5) Insert the reinforcing piece into the hole of the base bod...

Embodiment 2

[0057] A method for manufacturing a ZGM type repairable metal-ceramic composite grinding roller, comprising the steps of:

[0058] (1) Mix the pretreated and dried ceramic particles, alloy powder and binder in proportion, prepare a specific shape through a special mold, dry and shape it, and then prepare a preform by vacuum sintering;

[0059] (2) Take out the prefabricated body, put it in a 300°C oven, preheat it, and then fix it in the cavity of the casting sand mold, and finally prepare the block ceramic composite grinding roller skin by casting the alloy melt;

[0060] (3) Through heat treatment, the hardness of the single ceramic composite grinding roller skin reaches 62HRC, and then the ceramic composite grinding roller skin is machined to prepare the required size and shape;

[0061] (4) Casting the matrix and blocks designed on the drawings, and machining them to meet the matching requirements;

[0062] (5) Insert the reinforcing piece into the hole of the base body, ...

Embodiment 3

[0069] A method for manufacturing a ZGM type repairable metal-ceramic composite grinding roller, comprising the steps of:

[0070] (1) Mix the pretreated and dried ceramic particles, alloy powder and binder in proportion, prepare a specific shape through a special mold, dry and shape it, and then prepare a preform by vacuum sintering;

[0071] (2) Take out the prefabricated body, put it in an oven at 250°C for preheating, and then fix it in the cavity of the casting sand mold, and finally prepare the block ceramic composite grinding roller skin by casting the alloy melt;

[0072] (3) Through heat treatment, the hardness of the single ceramic composite grinding roller skin reaches 60HRC, and then the ceramic composite grinding roller skin is machined to prepare the required size and shape;

[0073] (4) Casting the matrix and blocks designed on the drawings, and machining them to meet the matching requirements;

[0074] (5) Insert the reinforcing piece into the hole of the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com