Plug-in PCBA connection terminals and electrical connection assemblies

A technology for electrical connection components and connection terminals, applied in the direction of connection, fixed connection, contact parts, etc., which can solve the problem of affecting the stability of the connection between the crimping terminal and the PCBA board, small elastic deformation of the crimping part, complex structure of the crimping part, etc. problems, to avoid the accumulation of assembly tolerances, prolong the service life, and increase the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

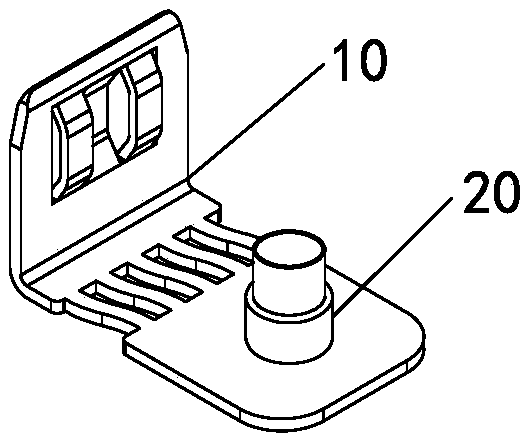

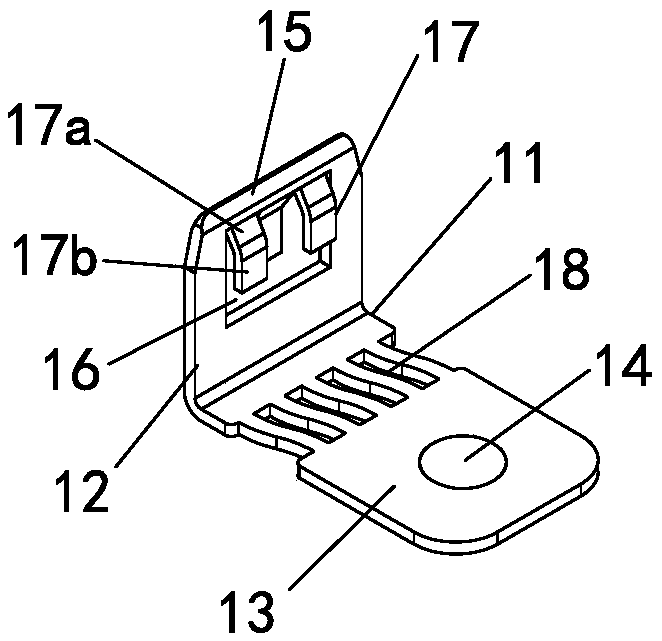

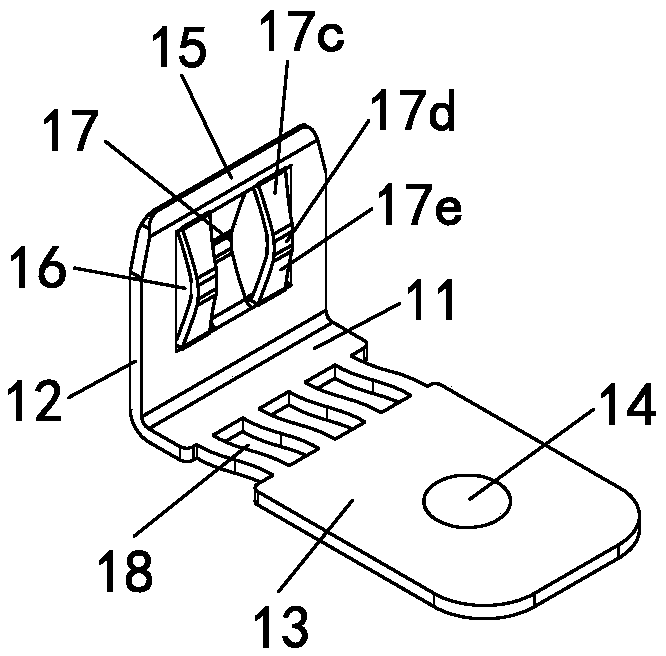

[0069] see figure 1 , which is a plug-in PCBA connection terminal provided by the present invention. The connection terminal includes a first metal terminal 10 and a second metal terminal 20 connected to each other, the first metal terminal is an integral piece made of copper for electrical connection with the PCBA board; the second metal terminal is made of aluminum One-piece piece for electrical connection to a mating connector made of aluminum.

[0070] Please also refer to figure 2 , the first metal terminal has a first connection body 11 . One end of the connecting body is the elastic portion 12 , and the other end is the first connecting portion 13 . The first connecting part is a plate structure, which is formed by extending forward from the connecting body, and a riveting hole 14 is arranged in the first connecting part. The elastic portion protrudes from the surface of the first connection body and forms an L shape with the connection body.

[0071] The elastic ...

Embodiment 2

[0083] See Figure 7 , as a modification of the first embodiment, the present invention also provides another connection terminal. Different from the first embodiment, the connection terminal includes a second metal terminal different from the second metal terminal described in the first embodiment.

[0084] The second metal terminal includes a second connection body 21 . One end of the second connection body is an electrical connection portion 22 , and the other end is a second connection portion 23 . The electrical connection part is a flat plate structure, which is welded by laser after it is pasted on the mating connector.

[0085] The second connecting portion is a plate structure, which is attached to the first connecting portion 13 of the first metal terminal 10 . There are three connection modes between the first connection part and the second connection part, as follows:

[0086] The first, see Figure 8 The first connecting portion of the first metal terminal an...

Embodiment 3

[0093] see Figure 12 , The invention provides an electrical connection assembly. The electrical connection assembly includes plastic parts 30 , bus bars 40 , PCBA board 50 and the connection terminals described in the first embodiment. The plastic part has a sealing holding part 31 that wraps and seals the riveting part. The electrical connection portion of the second metal terminal protrudes outside the seal holding portion. The bus bar has several outwardly extending lugs 41 (see Figure 13 ). The lug corresponding to the connection terminal has a connection hole 42 set on the electrical connection part, and then laser is used to weld the lug and the electrical connection part into one. The PCBA is provided with a socket 51; the wall surrounding the socket is coated with a conductive copper foil layer; the elastic part 12 of the first metal terminal is inserted into the socket, and the shrapnel elastically presses against the wall of the hole.

[0094] The seal holder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com