Flexible copper clad laminate and preparation method thereof

A copper foil and substrate technology, which is applied in the manufacture of printed circuits, the manufacture of printed circuit precursors, the improvement of metal adhesion of insulating substrates, etc., can solve problems such as environmental pollution, and achieve low dielectric constant and low dielectric loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

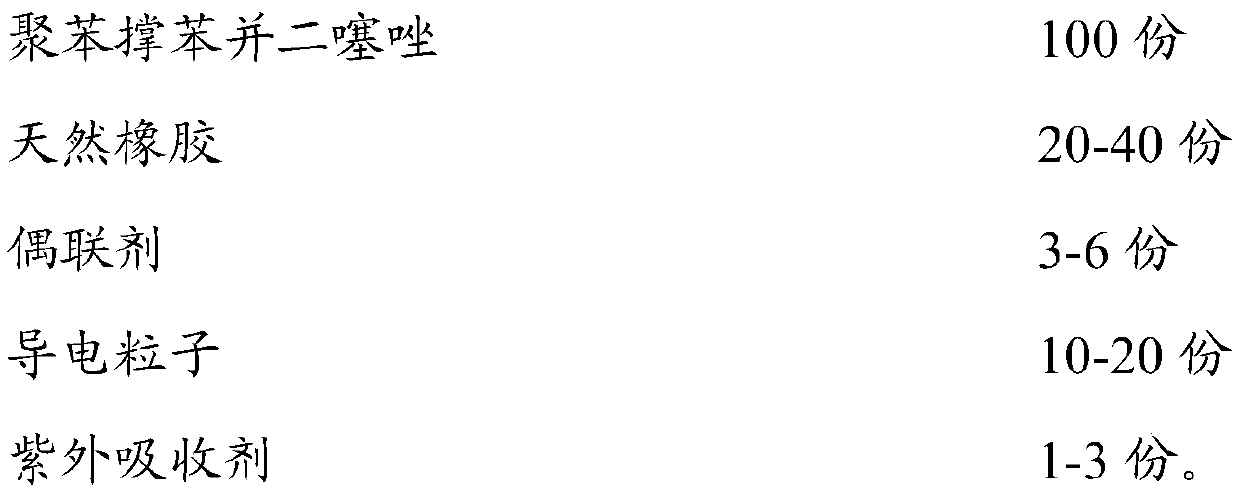

[0025] Embodiment 1 Flexible insulating base film

[0026]

[0027] The above-mentioned components are melted in a twin-screw extruder, mixed once, extruded, cooled, dried and pelletized, then the modified particles are melted again in a twin-screw extruder, and mixed twice, and finally Extruded, cast cast sheet and biaxially stretched into film, wound into roll.

[0028] The performance test of the prepared film was compared with the commercially available PI film, and the test results are shown in Table 1.

[0029] Table 1

[0030]

Embodiment 2

[0031] Embodiment 2 Film 1

[0032]

[0033] The above-mentioned components are melted in a twin-screw extruder, kneaded once, extruded, cooled, dried and pelletized for later use.

Embodiment 3

[0034] Embodiment 3 Adhesive film 2

[0035] The difference with embodiment 2 is that each component is composed, as follows:

[0036]

[0037] The functional masterbatches prepared in Examples 2 and 3 were melt-coated and cooled to form a film, and then the adhesive film was tested for performance testing. The test results are shown in Table 2.

[0038] Table 2

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com