A facile preparation method for low-cost high-strength repairable superhydrophobic coatings

A super-hydrophobic coating, high-strength technology, applied in coatings, epoxy resin coatings, etc., can solve the problems of high production cost of super-hydrophobic coating surface, complicated preparation or coating method, and difficult to prepare in large area. High mechanical strength, low cost and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

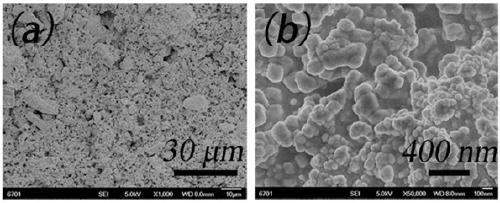

[0032] (1) Preparation of epoxy resin superhydrophobic suspension coating: 1.67g of metal oxide powder MgO, 0.33g of metal oxide powder P25 and 2g of stearic acid as a low surface energy modifier were added to a solvent of 20mL of acetone. After stirring for 10 minutes, 1.2 g of epoxy resin (E51) and its curing agent were added to the system at a ratio of 3:1, and after ultrasonic treatment for 20 minutes, the stirring was continued to obtain an epoxy resin superhydrophobic suspension coating.

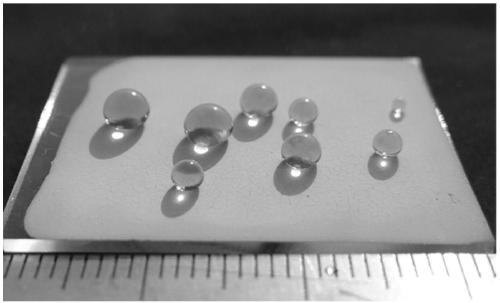

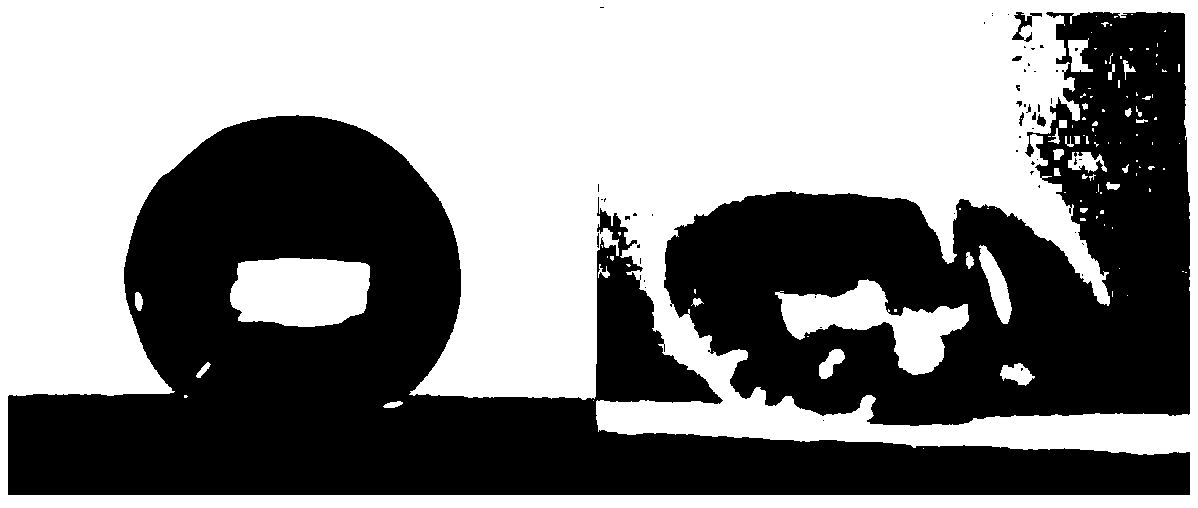

[0033] (2) Preparation of epoxy resin superhydrophobic coating: the epoxy resin superhydrophobic suspension coating obtained in step A was applied to the glass substrate by drop coating technique with a dropper. After curing and drying at 70°C for 5 hours, an epoxy superhydrophobic coating can be obtained on the glass substrate (see figure 1 ), the water droplets stand on its surface in a nearly perfect spherical shape. Its contact angle to water is 152°, and its rolling angle is abou...

Embodiment 2

[0036] (1) Preparation of epoxy resin superhydrophobic suspension coating: 1 g of metal oxide powder MgO, 1 g of metal oxide powder P25 and 2 g of stearic acid as a low surface energy modifier were added to 20 mL of acetone solvent. After stirring for 30 minutes, 1.2 g of epoxy resin (E51) and its curing agent were added to the system at a ratio of 3:1, and after ultrasonic treatment for 20 minutes, the stirring was continued to obtain an epoxy resin superhydrophobic suspension coating.

[0037] (2) Preparation of epoxy resin superhydrophobic coating: coating the epoxy resin superhydrophobic suspension obtained in step A, immersing the copper grid in the superhydrophobic suspension for a few seconds and slowly extracting it. After curing and drying at 70°C for 5 hours, an epoxy superhydrophobic coating can be obtained on the copper grid (see Figure 5 ), water droplets can also stand on its surface in a nearly perfect spherical shape.

Embodiment 3

[0039] (1) Preparation of epoxy resin superhydrophobic suspension coating: 1.67g of metal oxide powder MgO, 0.33g of metal oxide powder P25 and 2g of stearic acid as a low surface energy modifier were added to a solvent of 20mL of acetone. After stirring for 15 minutes, 1.2 g of epoxy resin (E51) and its curing agent were added to the system at a ratio of 3:1. After ultrasonic treatment for 60 minutes, the stirring was continued to obtain an epoxy resin superhydrophobic suspension coating.

[0040] (2) Preparation of epoxy resin superhydrophobic coating: the epoxy resin superhydrophobic suspension coating obtained in step A was applied to the glass substrate by drop coating technique with a dropper. After curing and drying at room temperature for 24 hours, an epoxy superhydrophobic coating can be obtained on the glass substrate.

[0041] (3) Repairable experiment: the obtained glass substrate with superhydrophobic coating is immersed in 1M sodium hydroxide solution for 30 seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com