Drive-control LED digital display screen

A drive control and display technology, applied to static indicators, instruments, identification devices, etc., can solve the problems of low installation efficiency of LED digital display, failure to realize drive control function, single display function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

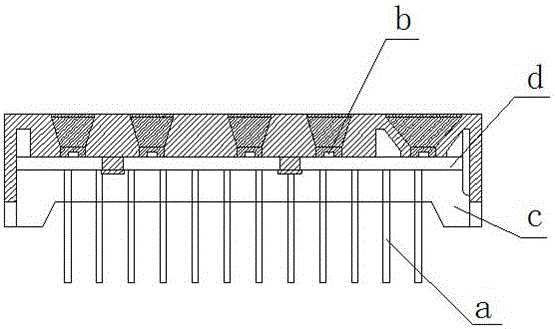

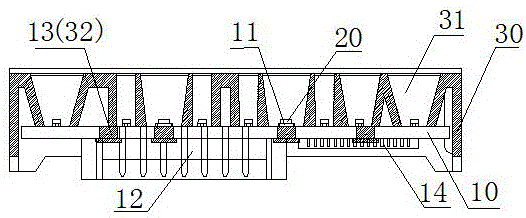

[0030] Such as figure 2 As shown, it shows a schematic diagram of a drive-controlled LED digital display provided by an embodiment of the present invention. The LED digital display includes: a PCB board 10, a preset number of LED patch lamps 20, and a plastic shell 30 ;

[0031] Wherein, the PCB board 10 includes a preset number of LED pads 11 arranged on the PCB board 10 according to a preset track, and the preset number of LED pads 11 are connected to the socket 12 through the circuit on the PCB board 10 and the general communication port. Corresponding to the connection, the PCB board 10 also includes an LED driver chip 14 integrated in the PCB board, and the PCB board 10 also includes a preset number of positioning holes 13 .

[0032] A preset number of LED patch lamps 20 are correspondingly mounted on a preset number of LED pads 11 on the PCB 10 by welding.

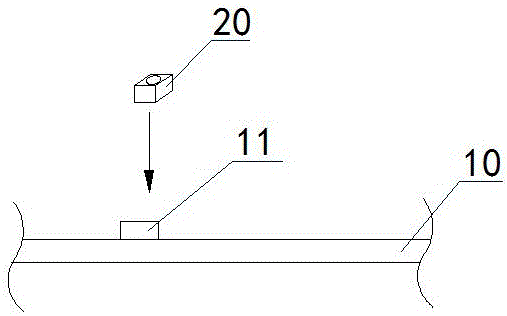

[0033] Such as image 3 As shown, it shows a schematic mounting diagram of an LED patch lamp provided by an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com