Composite material of mixed and knitted chemical fibers and natural veneers and preparation method of composite material

A chemical fiber and natural veneer technology, applied in chemical instruments and methods, woven fabrics, wood-layered products, etc., can solve the problems of complexity, shedding, and poor scratch resistance, saving forest resources and improving production efficiency. , The effect of clear and thorough wood grain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

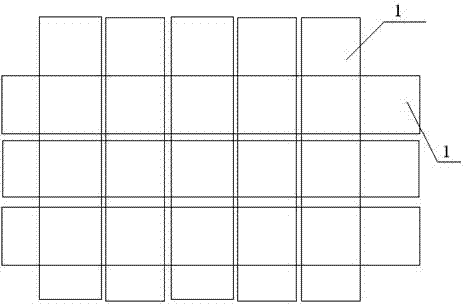

[0043] Such as figure 1 As shown, a composite material mixed with chemical fiber and natural veneer is braided by a composite fiber material (1) composed of chemical fiber and natural veneer with a thickness of 0.2mm, and the composite fiber material (1) is composed of The surface layer of natural veneer is compounded with the bottom layer of chemical fiber pre-impregnated with resin or the surface layer of glass fiber pre-impregnated with resin is compounded with the bottom layer of natural veneer. The chemical fiber is carbon fiber, aramid fiber, basalt fiber or glass fiber.

Embodiment 2

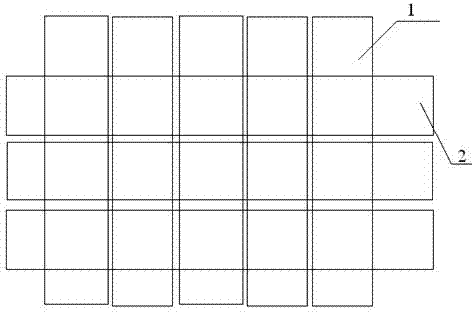

[0045] Such as figure 2 As shown, a composite material mixed with chemical fiber and natural veneer is woven from a composite fiber material (1) and chemical fiber (2) composed of chemical fiber and natural veneer with a thickness of 0.5mm. The composite fiber The material (1) is prepared by compounding the surface layer of natural wood veneer and the bottom layer of chemical fiber pre-impregnated with resin or by compounding the surface layer of glass fiber pre-impregnated with resin and the bottom layer of natural wood veneer. The chemical fiber is carbon fiber, aramid fiber, basalt fiber or glass fiber.

Embodiment 3

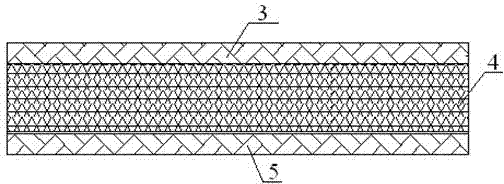

[0047] Such as image 3 As shown, a composite material product for an electrical housing, which includes an upper surface layer (3) made of composite material made of composite fiber materials (1) and a chemical fiber layer ( 4) A lower surface layer (5) made of a composite material woven with the composite fiber material (1) located below the chemical fiber layer (4).

[0048] The chemical fiber layer (4) is carbon fiber, aramid fiber, basalt fiber or glass fiber layer;

[0049] The composite fiber material (1) is prepared by compounding the surface layer of natural wood veneer and the bottom layer of chemical fiber pre-impregnated with resin or by compounding the surface layer of glass fiber pre-impregnated with resin and the bottom layer of natural wood veneer

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com