Hard alloy and method for producing hard alloy layer on surface of workpiece

A technology of hard alloy and workpiece surface, which is applied in the direction of manufacturing tools, metal processing equipment, gas flame welding equipment, etc., can solve the problem of high equipment requirements, achieve the effect of simple equipment, convenient operation, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The mass ratio of each component of the cemented carbide in this embodiment is: WC50%, Co30%, Mo20%, wherein 75-150 μm WC accounts for 10% of the whole WC powder.

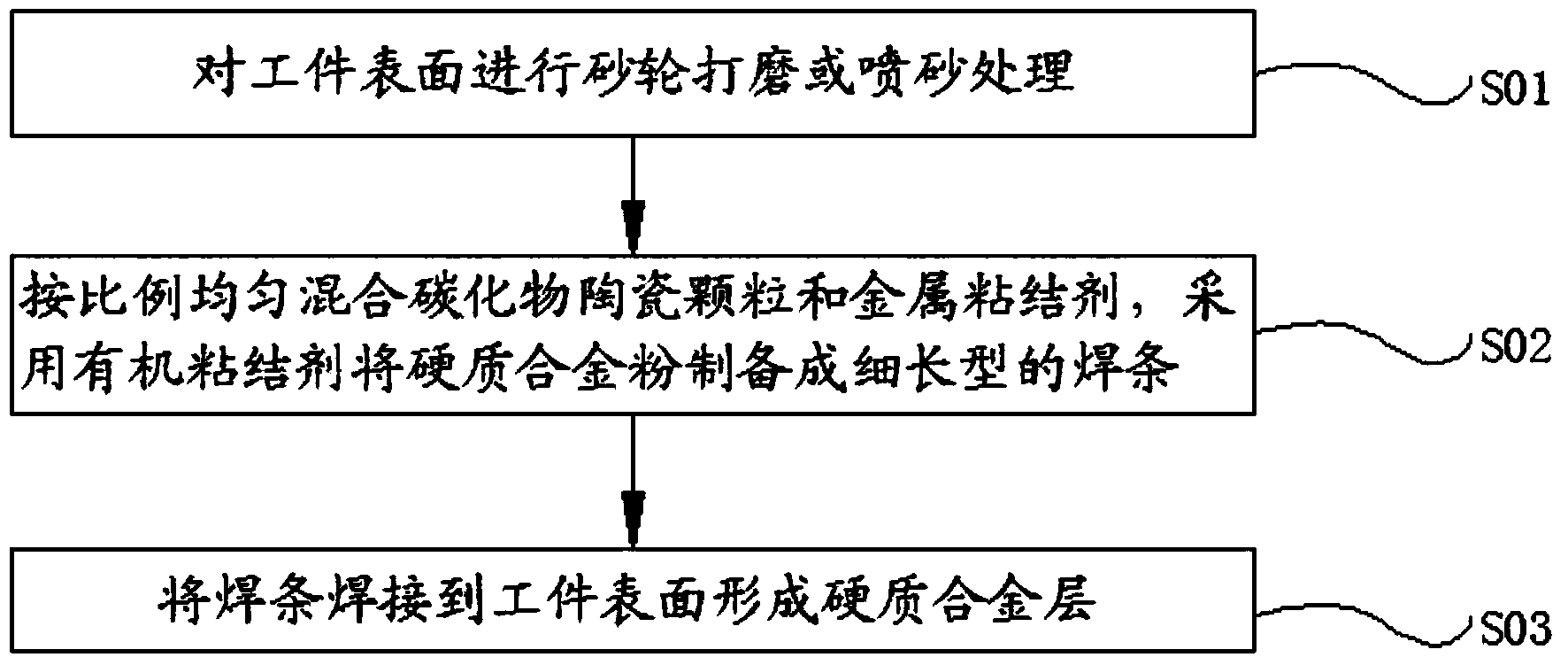

[0027] Manufacture the hard alloy layer on the surface of the workpiece according to the following process:

[0028] Step 1, grinding or sandblasting the surface of the workpiece;

[0029] Step 2, uniformly mixing the carbide ceramic particles and the metal binder according to the above ratio, and preparing the cemented carbide powder into a slender electrode by using an organic binder;

[0030] Step 3, welding the welding rod to the surface of the workpiece by means of flame welding to form a cemented carbide layer.

Embodiment 2

[0032] The mass ratio of each component of the cemented carbide in this embodiment is: WC 80%, Co 20%, wherein 75-150 μm WC accounts for 90% of the whole WC powder.

[0033] Manufacture the hard alloy layer on the surface of the workpiece according to the following process:

[0034] Step 1, grinding or sandblasting the surface of the workpiece;

[0035] Step 2, uniformly mixing the carbide ceramic particles and the metal binder according to the above ratio, and preparing the cemented carbide powder into a slender electrode by using an organic binder;

[0036] Step 3, welding the welding rod to the surface of the workpiece by means of flame welding to form a cemented carbide layer.

Embodiment 3

[0038] The mass ratio of each component of the cemented carbide in this embodiment is: WC65%, Co25%, Mo10%, wherein 75-150 μm WC accounts for 50% of the whole WC powder.

[0039] Manufacture the hard alloy layer on the surface of the workpiece according to the following process:

[0040] Step 1, grinding or sandblasting the surface of the workpiece;

[0041] Step 2, uniformly mixing the carbide ceramic particles and the metal binder according to the above ratio, and preparing the cemented carbide powder into a slender electrode by using an organic binder;

[0042] Step 3, welding the welding rod to the surface of the workpiece by means of flame welding to form a cemented carbide layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com