PC material with low blue light transmittance

A transmittance and blue light technology, applied in the field of low blue light transmittance PC materials, can solve the problems of poor environmental protection, reduce blue light transmittance, and reduce the transmittance of blue light absorbers, and achieve the effect of reducing the decrease in light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

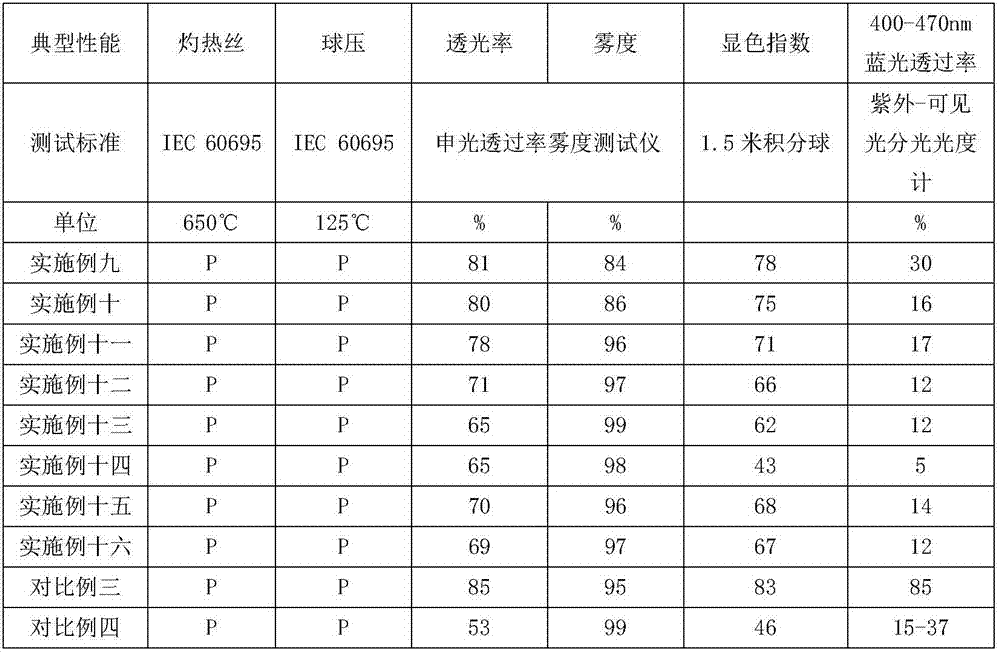

Examples

Embodiment 1

[0028] With HCL (hydrochloric acid), HNO 3 One or two mixtures of (nitric acid) to prepare a corrosive acid solution, in which HCL and HNO 3 The volume ratio is 10:1-3, the concentration of HCL is 1-2%, HNO 3 The concentration is 0.5-1%, in the acid solution, add the volume of HCL, HNO 3 The total volume of the mixed solution is 1-2%, and the concentration is 0.05% corrosion inhibitor LAN-826 to reduce the corrosion inhibition rate. Then put the light diffusing agent into the prepared corrosion acid solution for microporous corrosion, and the corrosion time is 13-17s. Then wash away the acid and corrosion inhibitor on the surface of the light diffusing agent with deionized water. A light diffusing agent with a micropore diameter of 0.05-0.08 μm is obtained.

[0029] According to the number of parts by mass, dry 1 part of light diffusing agent and 0.05 part of blue light absorbing agent at 75°C for 4-5 hours, and then add them to a high-speed mixer for mixing at a speed of ...

Embodiment 2

[0031] The pre-micropore treatment of the light diffusing agent is the same as in Example 1. According to the mass parts, 1 part of the light diffusing agent and 0.1 part of the blue light absorbing agent are dried at 75°C for 4-5 hours, and then mixed in a high-speed mixer at a speed of 4000-5000r / min, the blue light absorbing agent is filled in the micropores of the light diffusing agent, and the light diffusing-blue light absorbing agent of Example 2 is obtained.

Embodiment 3

[0033] The pre-micropore treatment of the light diffusing agent is the same as in Example 1. According to the mass parts, 1.5 parts of the light diffusing agent and 0.1 part of the blue light absorbing agent are dried at 75°C for 4-5 hours, and then mixed in a high-speed mixer at a speed of 4000-5000r / min, the blue light absorbing agent is filled in the micropores of the light diffusing agent, and the light diffusion-blue light absorbing agent of Example 3 is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com