Method for synthesizing dibutyl maleate

A technology for dibutyl malate and malic acid, which is applied in the field of synthesizing dibutyl malate, can solve the problems of difficulty in refining, corrosion of equipment, complicated post-treatment, etc., and achieves no environmental pollution, mild reaction conditions, and small amount of catalyst. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Step 1 Preparation of Naphthalene Sulfonate Methylal

[0016] Heat 10g of naphthalene to 160°C, then slowly add 10ml of concentrated sulfuric acid dropwise, heat and stir at 140°C for 5h, then cool to 100°C, add 2ml of water, add 10ml of formaldehyde solution dropwise, and keep heating at 100°C for 4h to get Add boiling water to the black solid, wash with suction, and dry at 120°C to obtain methylal of naphthalenesulfonic acid.

[0017] Step 2 Esterification

[0018] Add 0.1mol of malic acid, 0.25mol of n-butanol and 0.1g of naphthalenesulfonic acid methylal into a 100mL three-necked flask equipped with electromagnetic stirring, thermometer, reflux condenser and water separator, heat to reflux and stir, and heat to 90 °C, the water produced by the reaction is separated from the water separator, and the reaction is stopped until there is no water and then enters the water separator (about 3h).

[0019] Step 3 Catalyst separation and product purification

[0020] The m...

Embodiment 2-4

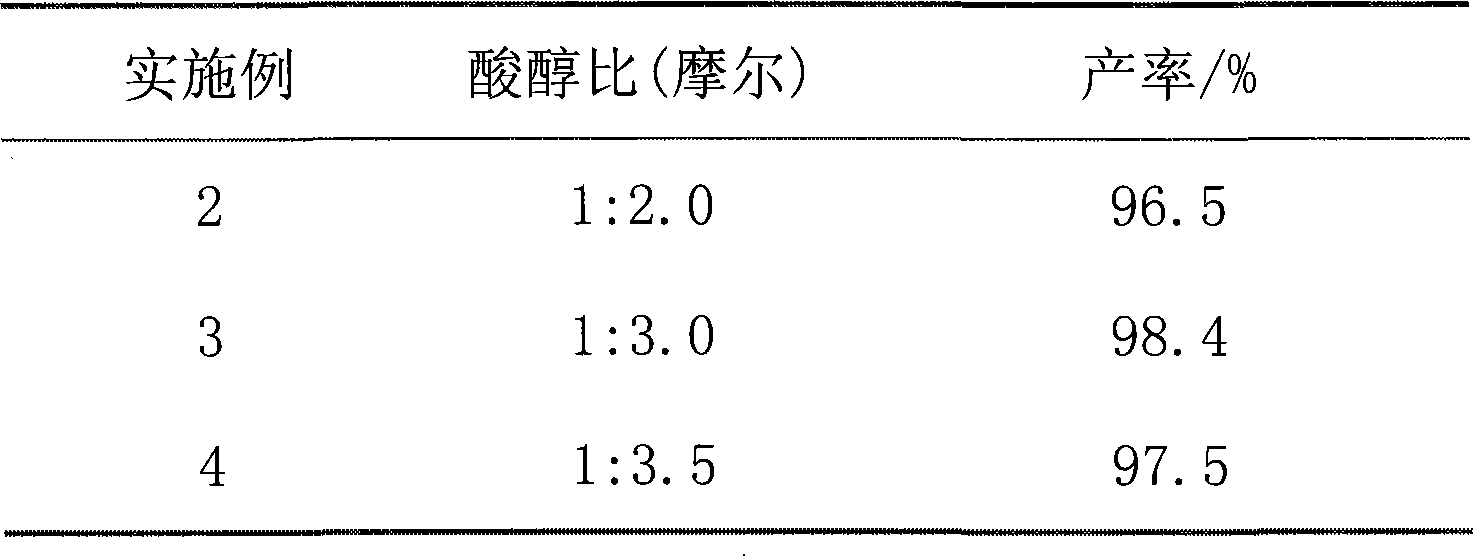

[0023] Except following difference, all the other are identical with embodiment 1, be 0.3g in naphthalenesulfonic acid methylal consumption, malic acid consumption is 0.1mol, n-butanol is by the ratio consumption of table 1.

[0024] Table 1

[0025]

Embodiment 5-7

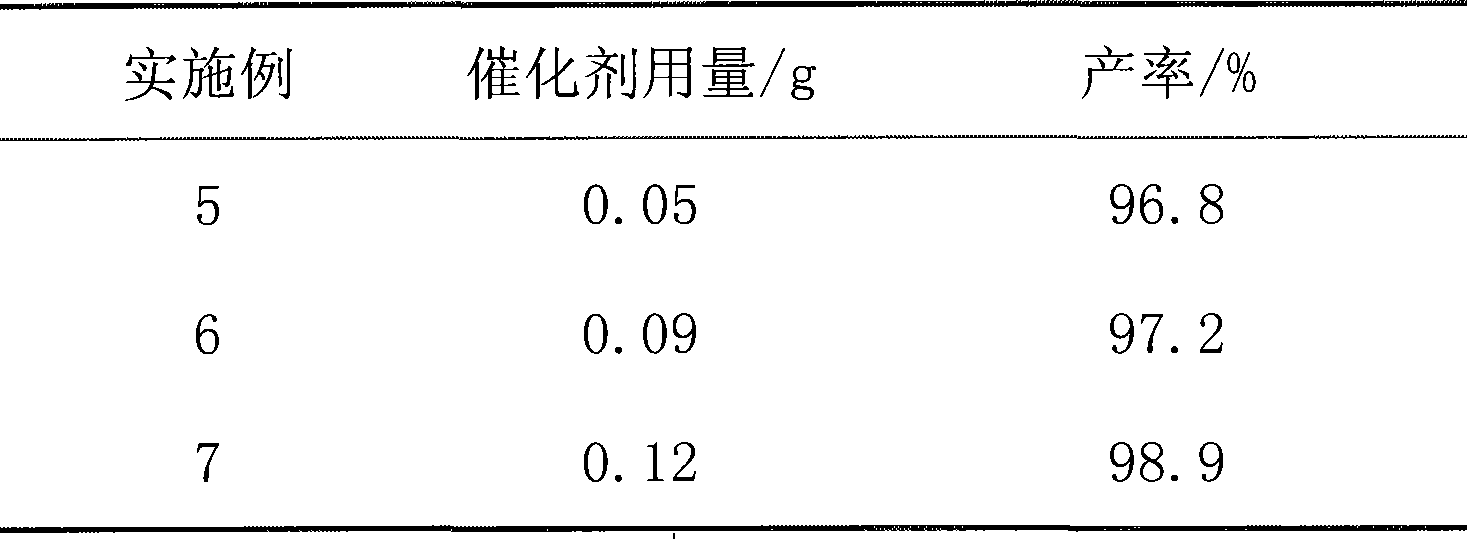

[0027] Except following difference, all the other are identical with embodiment 1, and the consumption of naphthalenesulfonic acid methylal is respectively by table 2.

[0028] Table 2

[0029]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com