Isolation coating of outer vamp of roller skate

A technology of isolation coating and roller skates, applied in the direction of coating, anti-corrosion coating, etc., can solve the problems of unusable, cracking, falling off, etc., to achieve the effect of product wear resistance, reasonable method and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

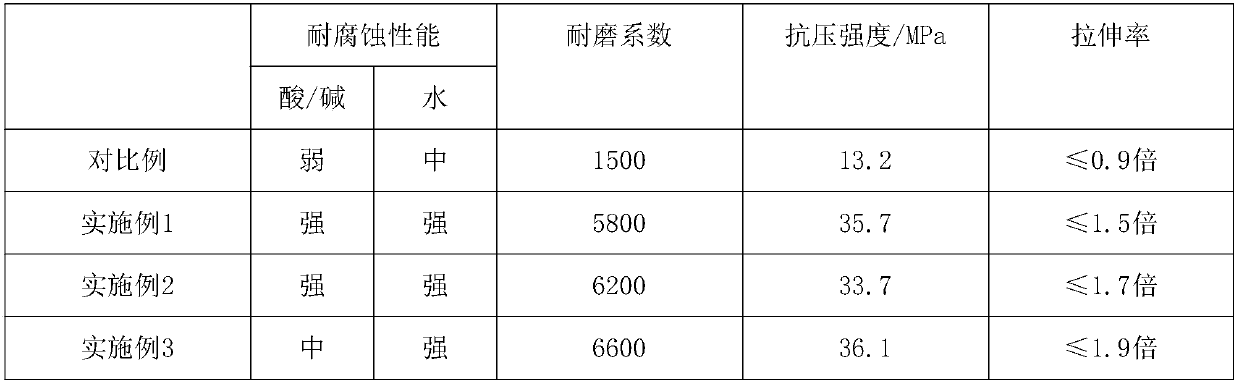

Examples

Embodiment 1

[0026] An isolation coating for the outer vamp of roller skates, characterized in that: it is made of the following materials by weight,

[0027] 13 parts of resin, 1 part of polydimethylsiloxane, 2 parts of dibutyl maleate, 1 part of 2,6-di-tert-butyl p-cresol, 7 parts of silane coupling agent KH-550, modified silicon 8 parts of algae earth, 1 part of lauric acid diethanolamide, 1 part of hydrogenated castor oil, 1 part of N-methylolacrylamide, 8 parts of ethanol, 8 parts of anti-aging agent, 9 parts of biological auxiliary agent, 27 parts of deionized water;

[0028] Described resin is the one in polyester resin, C5 petroleum resin, epoxy resin, methacrylic resin, phenolic resin;

[0029] Described anti-aging agent is the one in anti-aging agent IPPD, anti-aging agent H, 4.4-two (2.2-dimethylbenzyl) diphenylamine, anti-aging agent 264;

[0030] The preparation method of the modified diatomite powder is as follows: grind the diatomite and pass through a 400-500 mesh sieve, t...

Embodiment 2

[0042] An isolation coating for the outer vamp of roller skates, characterized in that: it is made of the following materials by weight,

[0043] 20 parts of resin, 4 parts of polydimethylsiloxane, 6 parts of dibutyl maleate, 3 parts of 2,6-di-tert-butyl p-cresol, 11 parts of silane coupling agent KH-550, modified silicon 13 parts of algae earth, 5 parts of lauric acid diethanolamide, 4 parts of hydrogenated castor oil, 4 parts of N-methylolacrylamide, 13 parts of ethanol, 13 parts of anti-aging agent, 13 parts of biological auxiliary agent, 33 parts of deionized water;

[0044] Described resin is the one in polyester resin, C5 petroleum resin, epoxy resin, methacrylic resin, phenolic resin;

[0045] Described anti-aging agent is the one in anti-aging agent IPPD, anti-aging agent H, 4.4-two (2.2-dimethylbenzyl) diphenylamine, anti-aging agent 264;

[0046] The preparation method of the modified diatomite powder is as follows: grind the diatomite and pass through a 400-500 mes...

Embodiment 3

[0058] An isolation coating for the outer vamp of roller skates, characterized in that: it is made of the following materials by weight,

[0059] 16 parts of resin, 2 parts of polydimethylsiloxane, 3 parts of dibutyl maleate, 2 parts of 2,6-di-tert-butyl p-cresol, 10 parts of silane coupling agent KH-550, modified silicon 11 parts of algae earth, 3 parts of lauric acid diethanolamide, 2 parts of hydrogenated castor oil, 3 parts of N-methylolacrylamide, 12 parts of ethanol, 9 parts of anti-aging agent, 10 parts of biological auxiliary agent, 31 parts of deionized water;

[0060] Described resin is the one in polyester resin, C5 petroleum resin, epoxy resin, methacrylic resin, phenolic resin;

[0061] Described anti-aging agent is the one in anti-aging agent IPPD, anti-aging agent H, 4.4-two (2.2-dimethylbenzyl) diphenylamine, anti-aging agent 264;

[0062] The preparation method of the modified diatomite powder is as follows: grind the diatomite and pass through a 400-500 mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com