High-oil-resistance high-wear-resistance sealing gasket and preparation method thereof

A technology of wear resistance and oil resistance, which is applied in the field of sealing gaskets with good oil resistance and wear resistance and its preparation, can solve the problems of poor elasticity, oil resistance, wear resistance and unsatisfactory strength, etc., and achieve long service life , Improve the tensile properties and mechanical properties, improve the effect of wear resistance and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

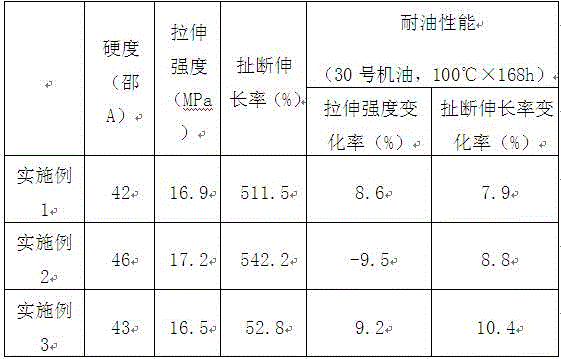

Embodiment 1

[0013] Example 1, a sealing gasket with good oil resistance and wear resistance, made of the following raw materials in parts by weight (kg): nitrile rubber 52, natural rubber 6, silicone rubber 8, halloysite 7, spherical silica powder 4 , carbon black N660 22, zinc stearate 1, dibutyl maleate 2, zinc oxide 3, aluminum oxide 2, polyethylene glycol 2, sodium tripolyphosphate 1, silane coupling agent KH5501, Nano chromium boride 2, nano carbon sol 2, antioxidant RD1, rosin 2, castor oil 1.

[0014] A preparation method of a sealing gasket with good oil resistance and wear resistance, comprising the following steps:

[0015] (1) Calcinate the halloysite at 460°C for 3 hours, take it out, cool it, and grind it into powder, then add sodium tripolyphosphate and nano-chromium boride, mix and stir for 35 minutes, then spray into the silane coupling agent KH550, at 14000r Stir for 55 minutes under / min to obtain modified halloysite for subsequent use;

[0016] (2) Mix spherical silic...

Embodiment 2

[0019] Example 2, a gasket with good oil resistance and wear resistance, made of the following raw materials in parts by weight (kg): nitrile rubber 54, natural rubber 7, silicone rubber 9, halloysite 8, spherical silica powder 5 , carbon black N660 23, zinc stearate 2, dibutyl maleate 3, zinc oxide 4, aluminum oxide 3, polyethylene glycol 3, sodium tripolyphosphate 2, silane coupling agent KH5502, Nano chromium boride 3, nano carbon sol 3, antioxidant RD2, rosin 3, castor oil 2.

[0020] A preparation method of a sealing gasket with good oil resistance and wear resistance, comprising the following steps:

[0021] (1) Calcinate the halloysite at 480°C for 4 hours, take it out, cool it, and grind it into powder, then add sodium tripolyphosphate and nano-chromium boride, mix and stir for 40 minutes, then spray into the silane coupling agent KH550, at 15000r Stir for 60 minutes under / min to obtain modified halloysite for subsequent use;

[0022] (2) Mix spherical silica powder...

Embodiment 3

[0025] Example 3, a gasket with good oil resistance and wear resistance, made of the following raw materials in parts by weight (kg): nitrile rubber 56, natural rubber 8, silicone rubber 10, halloysite 9, spherical silica powder 6 , carbon black N660 24, zinc stearate 3, dibutyl maleate 4, zinc oxide 5, aluminum oxide 4, polyethylene glycol 4, sodium tripolyphosphate 3, silane coupling agent KH5503, Nano chromium boride 4, nano carbon sol 4, antioxidant RD3, rosin 4, castor oil 3.

[0026] A preparation method of a sealing gasket with good oil resistance and wear resistance, comprising the following steps:

[0027] (1) Calcinate halloysite at 500°C for 5 hours, take it out, cool it, and grind it into powder, then add sodium tripolyphosphate and nano-chromium boride, mix and stir for 45 minutes, then spray into silane coupling agent KH550, at 16000r Stir for 65 minutes under / min to obtain modified halloysite for subsequent use;

[0028] (2) Mix spherical silicon micropowder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com