Polyethylene glue nucleation melting-boosting adhesive special for oil and gas pipelines

A technology for oil and gas pipelines and polyethylene, applied in the direction of adhesives, grafted polymer adhesives, adhesive types, etc., can solve the problems of mechanical strength and tensile properties, insufficient anti-corrosion function, and impact on anti-corrosion performance, etc., to achieve High mechanical strength and thermal stability, prevention of insufficient mechanical properties, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Raw material ratio:

[0042] Raw material: polyethylene, white granular chips, molecular weight 60000-70000g / mol

[0043] Reaction monomer: maleic anhydride, content≥99%, melting point, 51-54℃

[0044] Initiator: Dibenzoyl peroxide

[0045]Nucleating agent: 1,3,2,4-bis(3-methyl4-benzyl)sorbitol

[0046] Antioxidant: main antioxidant 1010, auxiliary antioxidant 618; carbon black

[0047] Raw material ratio: polyethylene 68%, reaction monomer 10%, initiator 0.5%, nucleating agent 1%, carbon black 20%, antioxidant 0.5% (all are mass percentages, of which the main antioxidant is 0.4%, Co-antioxidant 0.1%).

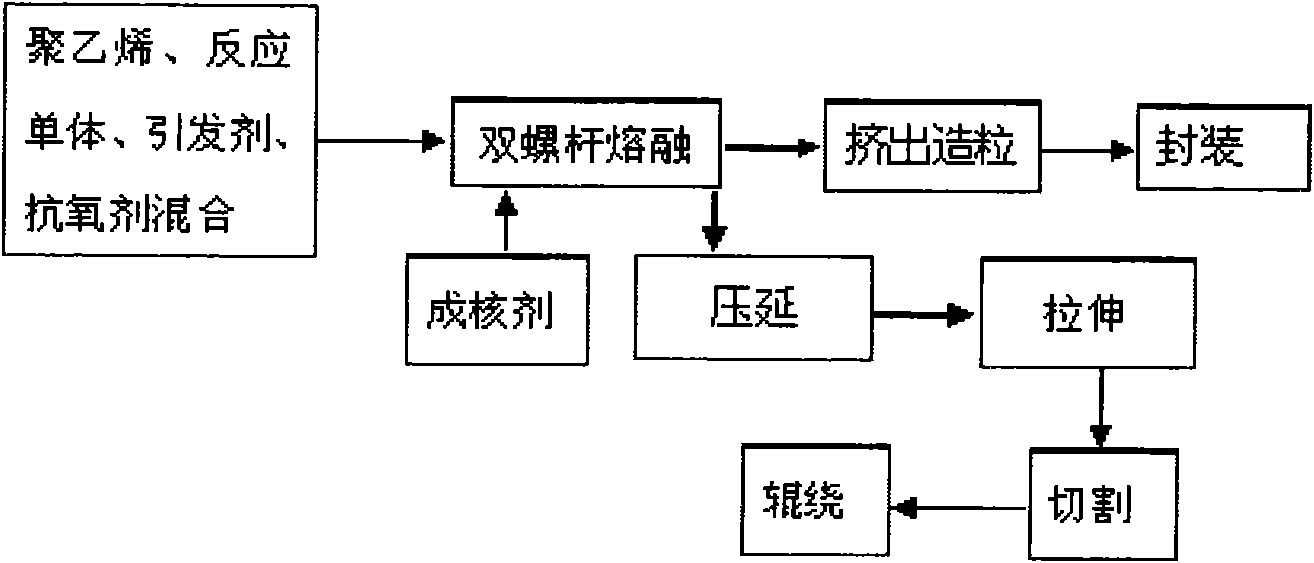

[0048] (2) Preparation method:

[0049] A preparation method of a film made from a polyethylene glue nucleating and melting adhesive specially used for oil and gas pipelines:

[0050] Mix the polyethylene, reaction monomer, initiator and antioxidant evenly and feed them into the twin-screw extruder. Control the rotational speed of the screw extruder to make th...

Embodiment 2

[0057] (1) Raw material ratio:

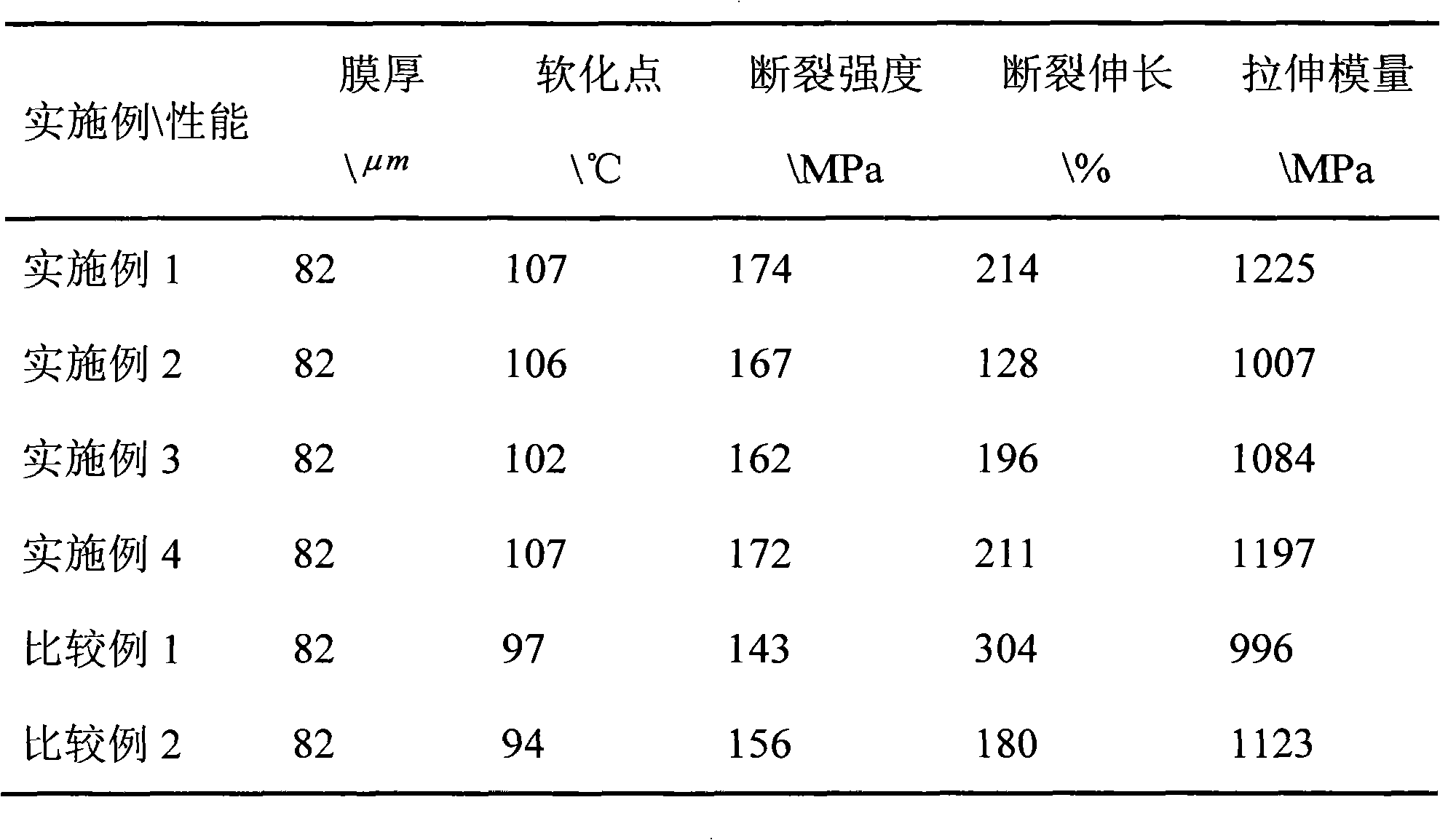

[0058] Except for polyethylene 63%, maleic anhydride 15%, and dicumyl peroxide 0.5%, the composition of other raw materials is the same as that of Example 1, and the properties of the obtained polyethylene jacket material film are shown in Table 1.

[0059] (2) Preparation method:

[0060] The preparation method is the same as in Example 1.

Embodiment 3

[0062] (1) Raw material ratio:

[0063] Except that the reaction monomer uses dibutyl maleate, the initiator is di-tert-butane peroxide, and other raw material compositions are the same as those in Example 1. The properties of the obtained polyethylene jacket material film are shown in Table 1.

[0064] (2) Preparation method:

[0065] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com