Water-based steel structural anti-corrosive coating and preparation method thereof

A technology for anti-corrosion coatings and steel structures, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of increased construction difficulty, complex coating process, harsh working conditions, etc., to achieve simple construction and good anti-corrosion performance, reduce labor intensity. , The effect of super weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with examples.

[0035] First prepare carbon-titanium modified acrylic resin according to the following steps:

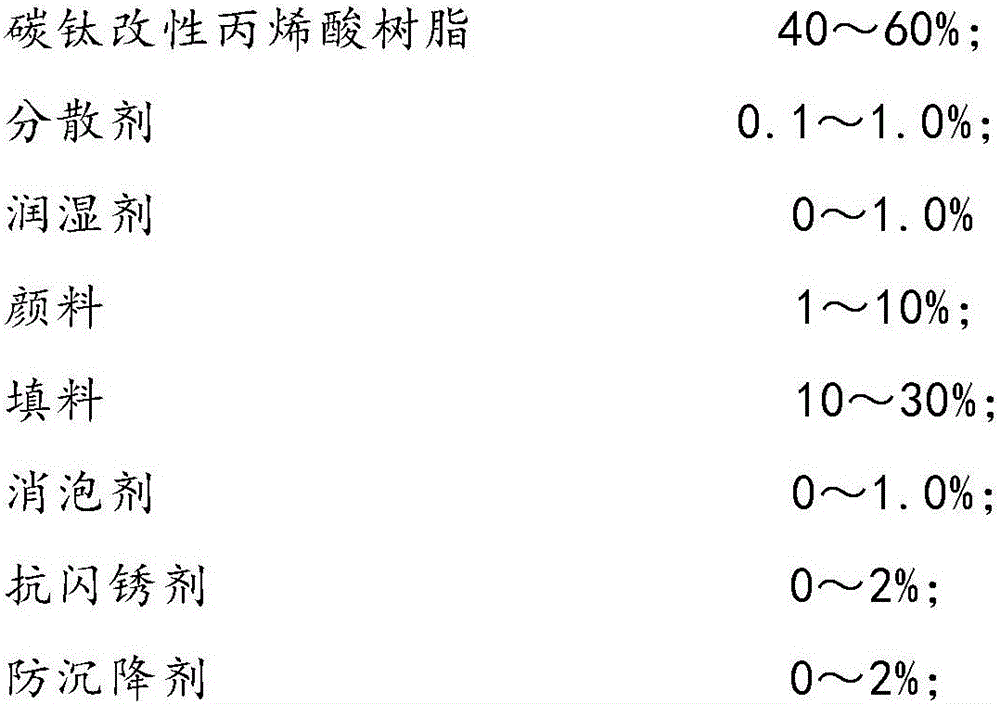

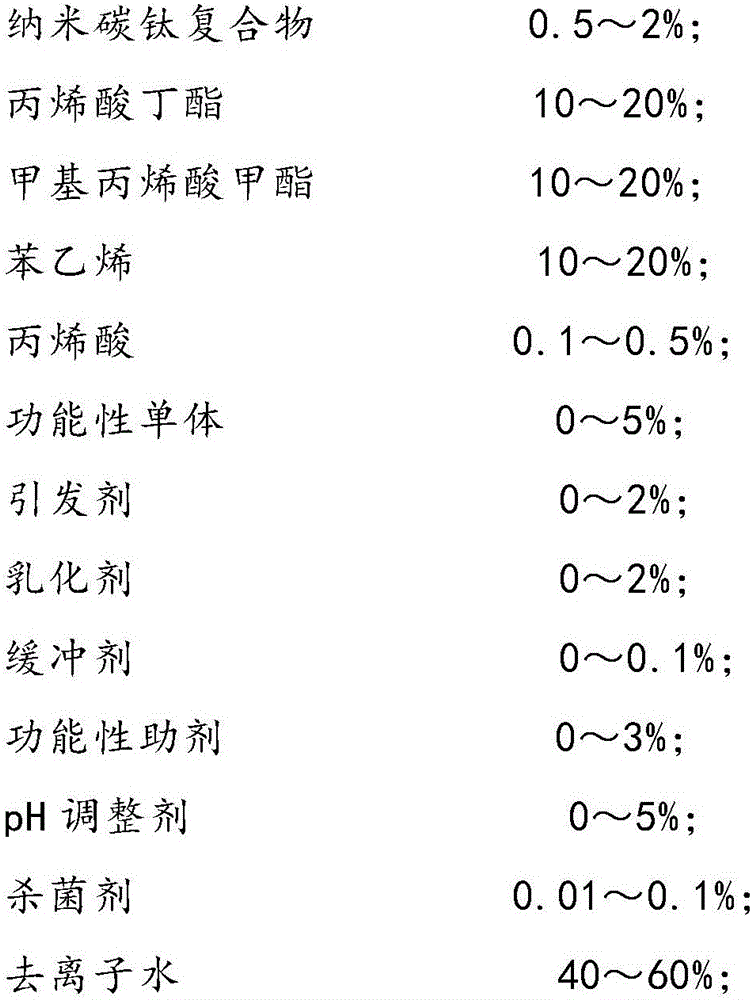

[0036] (1) Take the raw materials of the following quality:

[0037]

[0038]

[0039] (2) Put 2400g of deionized water, 500g of nano-carbon-titanium composite and 3g of ammonium bicarbonate into the reactor and stir to raise the temperature to 88°C;

[0040] (3) 2300g deionized water, 400g nano-carbon-titanium composite and 20g sulfosuccinate are dropped into the pre-emulsification kettle under agitation state and drop into all butyl acrylate, methyl methacrylate, styrene and acrylic acid, stir for 30 Take out after minutes;

[0041] (4) Add the mixed liquid of step (3) into the reaction kettle that has been heated to 88° C. and stir;

[0042] (5) remove 200g deionized water and 30g ammonium persulfate and make solution;

[0043] (6) half of the solution obtained in step (5) is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com