Special decorative mortar for lightweight thermal insulation walls

A technology for insulating walls and plastering mortar, which is applied in the field of construction mortar, which can solve problems such as inability to paint the plastering mortar, falling off, and cracking of the plastering mortar, and achieve excellent water retention, safe raw materials, and simple construction methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

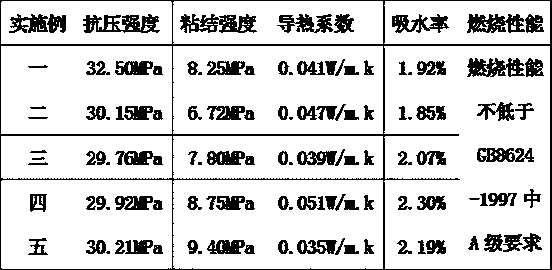

Examples

Embodiment 1

[0015] The special plastering mortar for lightweight thermal insulation walls proposed by the present invention is composed of the following raw materials and water in parts by weight, wherein the mass ratio of raw materials to water is 6: 1.2, and the raw materials in parts by weight are: 45 parts of cement, 12 parts of calcined gypsum , 18 parts of slag fine powder, 22 parts of polyphenylene particles and vitrified microbead composition, 1.5 parts of polyurethane fiber, 3 parts of polyacrylate emulsion, 0.5 part of mortar water retaining agent, and 3 parts of additives.

[0016] Among them, the additives include titanium dioxide, sodium methyl silicate, diffusing agent, coupling agent, wherein the weight percentage of each component is: titanium dioxide 30%, sodium methyl silicate 28%, diffusing agent 22%, coupling agent 20% , the total weight percentage is 100%.

[0017] Its preparation method comprises the following steps:

[0018] S1. After the polyurethane fiber of the ...

Embodiment 2

[0021] The special plastering mortar for lightweight thermal insulation walls proposed by the present invention is composed of the following raw materials and water in parts by weight, wherein the mass ratio of raw materials to water is 4.5: 1.2, and the raw materials in parts by weight are: 30 parts of cement and 15 parts of calcined gypsum , 20 parts of slag fine powder, 25 parts of polystyrene particles and ceramsite composition, 1 part of polyurethane fiber, 6 parts of polyacrylate emulsion, 0.3 part of mortar water retaining agent, and 4 parts of additives.

[0022] Among them, the additives include titanium dioxide, sodium methyl silicate, diffusing agent, coupling agent, wherein the weight percentage of each component is: titanium dioxide 32%, sodium methyl silicate 22%, diffusing agent 22%, coupling agent 24% , the total weight percentage is 100%.

[0023] Its preparation method comprises the following steps:

[0024] S1. Cut the polyurethane fiber of the specific gra...

Embodiment 3

[0027] The special plastering mortar for lightweight thermal insulation walls proposed by the present invention is composed of the following raw materials and water in parts by weight, wherein the mass ratio of raw materials to water is 5:1, and the raw materials in parts by weight are: 35 parts of cement and 10 parts of calcined gypsum , 25 parts of slag fine powder, 28 parts of expanded perlite and polystyrene particle composition, 1.8 parts of polyurethane fiber, 5 parts of polyacrylate emulsion, 0.8 part of mortar water retaining agent, and 2 parts of additives.

[0028] Among them, the additives include titanium dioxide, sodium methyl silicate, diffusing agent, coupling agent, wherein the weight percentage of each component is: titanium dioxide 30%, sodium methyl silicate 25%, diffusing agent 25%, coupling agent 20% , the total weight percentage is 100%.

[0029] Its preparation method comprises the following steps:

[0030] S1. Cut the polyurethane fiber of the specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com